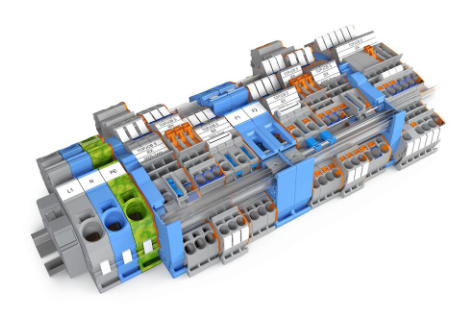

EMERSON DeltaV KJ2231X1-EE1 SIS Current limiter

It is a key component in the Emerson DeltaV Safety Instrumentation System (SIS). SIS is a safety protection system for monitoring and controlling potentially hazardous situations, and it plays a crucial role in industrial automation and process control. KJ2231X1-EE1 Current limiter is a safety current limiting device in SIS, which is used to limit and regulate the flow of process fluids to ensure that the process operates within a safe range.

EMERSON DeltaV KJ2231X1-EE1 SIS Current limiter

It is a key component in the Emerson DeltaV Safety Instrumentation System (SIS). SIS is a safety protection system for monitoring and controlling potentially hazardous situations, and it plays a crucial role in industrial automation and process control. KJ2231X1-EE1 Current limiter is a safety current limiting device in SIS, which is used to limit and regulate the flow of process fluids to ensure that the process operates within a safe range.

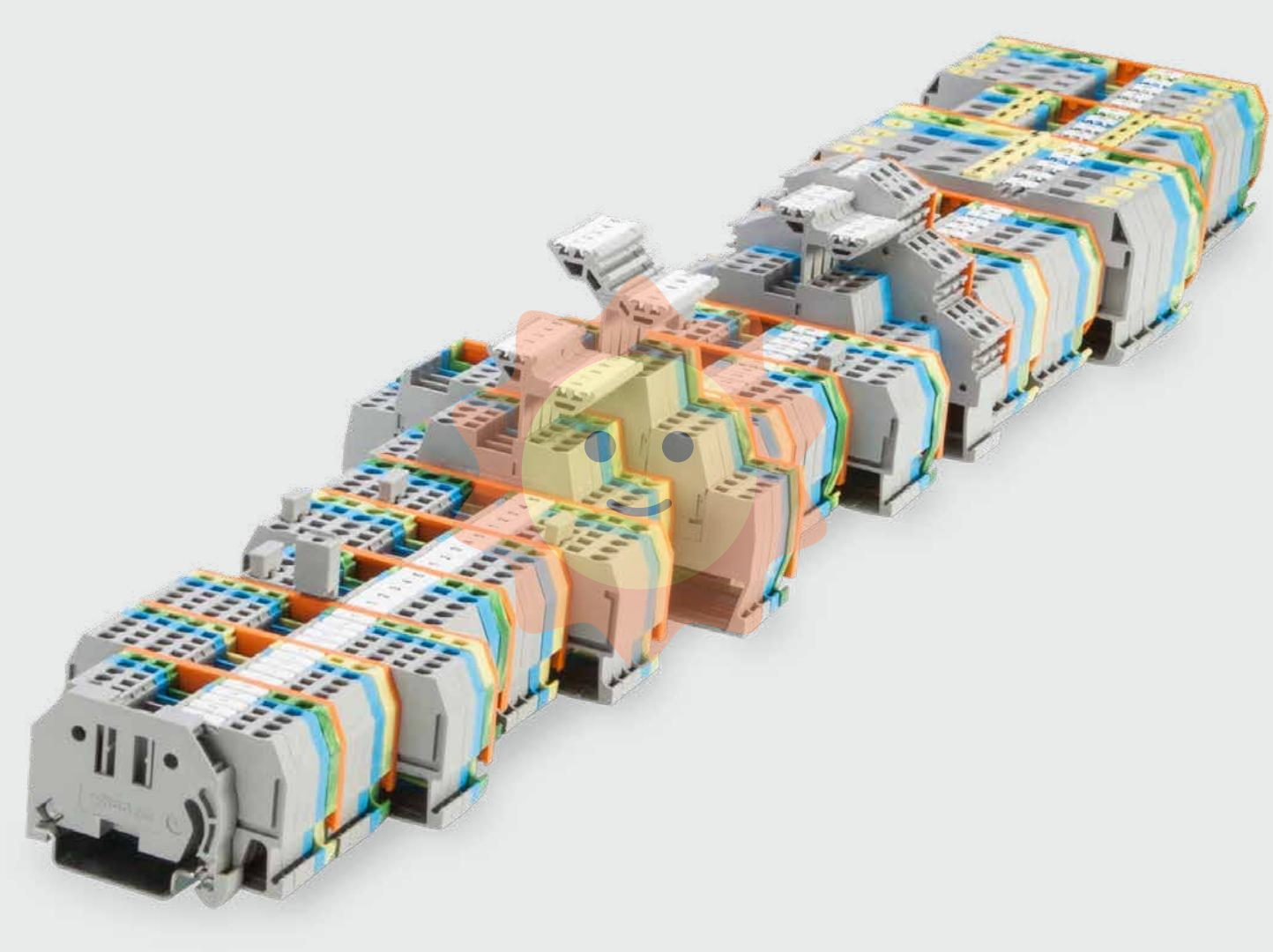

Main function

Flow limit: The KJ2231X1-EE1 current limiter is capable of monitoring and limiting the flow of fluid in the pipeline to prevent exceeding preset safety limits.

Safety protection: In the event of abnormal conditions or potential hazards, the current limiter can respond quickly to prevent accidents or mitigate their effects by restricting flow.

Fail-safe: The current limiter is designed to be fail-safe, that is, in the event of a failure, it will automatically take safety measures to ensure that the process will not get out of control.

Application scenario

KJ2231X1-EE1 SIS current limiter is usually used in industrial processes requiring high safety protection, such as petrochemical, natural gas processing, pharmaceutical, nuclear energy and other fields. In these scenarios, the current limiter ensures the stability and safety of the process, reducing potential risks and accidents.

Technical characteristics

Fast response: the current limiter has the ability to respond quickly and can make accurate judgments and responses to abnormal situations in a short time.

High precision measurement: The use of advanced flow measurement technology, can accurately monitor the flow changes in the pipeline.

High reliability: The current limiter is subject to strict quality control and testing to ensure stable operation in harsh industrial environments.

Easy integration: The current limiter can be easily integrated into existing DeltaV SIS systems to work in conjunction with other safety instrumentation.

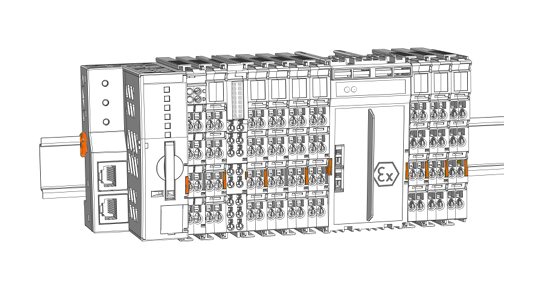

Configuration and setup

Configuring and setting up the KJ2231X1-EE1 SIS current limiter usually involves the following steps:

Parameter setting: According to the process requirements and safety standards, set the flow limit of the current limiter, response time and other key parameters.

System integration: The current limiter is integrated with other components in the DeltaV SIS system to ensure that information flows and works together.

Debugging and testing: After completing the configuration, debug and test the system to verify whether the function and performance of the current limiter meet the expected requirements.

Regular maintenance: Maintain and check the current limiter regularly to ensure its long-term stable operation.

Matters needing attention

When configuring and setting up the current limiter, be sure to follow the official documentation and guidelines provided by Emerson.

The current limiter parameters should be set reasonably according to the actual process flow and safety requirements.

Ensure compatibility and collaboration with other safety instruments during system integration and commissioning.

Maintain and check the current limiter regularly to identify and resolve potential problems in time.

Choose Xiamen control Smith after sale worry

Excellent product quality

Only cooperate with manufacturers of first-line brands in the industry

Imports/Products

Good pre-sale service

Communicated with customers repeatedly about product model, quality, price and delivery date

Work with the customer to determine the best solution

Address user concerns in advance

Business execution in place

Ordered products delivered on time

Make perfect delivery plan to ensure the time limit

Assist users to handle the acceptance procedures

Perfect after-sales service

During the warranty period, problems will only be replaced and not repaired

Never put a problem on the back of your head

Service hotline 7x24 hours service

Solemn promise

1. All the items sold by the company, module card parts, etc., the quality problems arising from normal use during the warranty period are replaced free of charge, and there is no evasion.

2. For materials and equipment that have not been discontinued beyond the warranty period, only the cost of relevant parts will be charged for quality problems.

3. Provide replacement models and equipment replacement process services for discontinued materials and equipment.

4. Customers have purchased materials and equipment, lifetime free upgrade system software, related technical information provided free of charge.

5. Visit the use of materials purchased by customers from time to time, and solve any problems in time.

6. The company hotline provides 24-hour service, and the questions raised by customers are answered within 1 hour.

7. Not done, the company spirit of "thoughtful service, responsible to the end" attitude, from the customer's point of view to solve the problem, with serious and rigorous enterprise style, dedicated to each customer service.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com