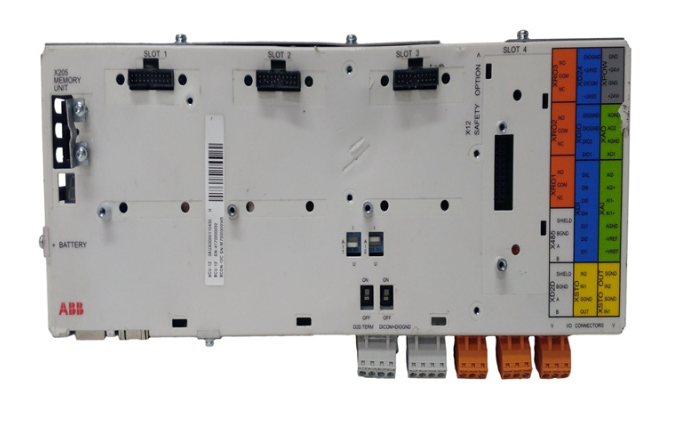

This module is a high-performance input module developed by ABB for industrial automation control systems. Its model system includes multiple key identifiers, and the meanings and core information of each part are as follows:

-Core model: 500CSP04, representing the module belonging to ABB 500 series, is a CSP series input module focused on signal acquisition. "04" usually corresponds to specific channel configurations or functional specifications.

-Part number: HE401314/0002, is the production and inventory management identifier for the module, where "0002" may represent the production batch or version number, used to distinguish products with different production cycles.

-Order number: 1MRB150051R2, is the core identifier for customer procurement and ABB internal material management. "R2" usually indicates that the module is designed for version 2 and may have been optimized for stability or compatibility compared to earlier versions.

-Applicable system: It is mainly compatible with ABB AC 500 series PLC (programmable logic controller) and is a key component for achieving on-site signal access in this series of control systems.

ABB 500CSP04 HE401314/0002 1MRB150051R2 Input Module

Basic information of module

This module is a high-performance input module developed by ABB for industrial automation control systems. Its model system includes multiple key identifiers, and the meanings and core information of each part are as follows:

-Core model: 500CSP04, representing the module belonging to ABB 500 series, is a CSP series input module focused on signal acquisition. "04" usually corresponds to specific channel configurations or functional specifications.

-Part number: HE401314/0002, is the production and inventory management identifier for the module, where "0002" may represent the production batch or version number, used to distinguish products with different production cycles.

-Order number: 1MRB150051R2, is the core identifier for customer procurement and ABB internal material management. "R2" usually indicates that the module is designed for version 2 and may have been optimized for stability or compatibility compared to earlier versions.

-Applicable system: It is mainly compatible with ABB AC 500 series PLC (programmable logic controller) and is a key component for achieving on-site signal access in this series of control systems.

Core functions and performance parameters

1. Core functions

As an input module, its core function is to collect, convert, and isolate various analog or digital signals from industrial sites, convert them into standard digital signals recognizable by PLCs, and provide accurate data support for logical operations and decision-making of control systems. Specific functions include:

-Signal acquisition and conversion: Accurately collect signals output by on-site sensors, transmitters, and other devices, complete the conversion between analog signals (such as current and voltage) and digital signals, or directly collect digital signals (such as switch status).

-Electrical isolation: It has a complete electrical isolation function, effectively isolating signals from the field side and system side, avoiding electromagnetic interference, surges and other factors that may affect the PLC system, and improving the system's anti-interference ability.

-Status monitoring: Some models support module self working status monitoring, such as power failure, channel failure, etc., which are fed back to the PLC through specific signals, making it easy for operation and maintenance personnel to quickly locate problems.

-Hot swappable compatibility (partial versions): If the module supports hot swappable functionality, module replacement can be completed without shutting down the PLC system, reducing system downtime and improving production continuity.

2. Key performance parameters

The following are typical performance parameters of the module (refer to the product manual for details):

-Input type: Commonly used are analog inputs (such as 4-20mA DC current, 0-10V DC voltage) or digital inputs (such as 24V DC switch signal), which need to be confirmed based on the actual model.

-Number of input channels: usually 4 channels (combined with the "04" model identification), supporting multi-channel simultaneous acquisition, with independent channels to avoid signal crosstalk.

-Accuracy level: The analog input accuracy can generally reach ± 0.1% FS (full range), ensuring the accuracy of collected data and meeting the precision requirements of industrial control.

-Response time: Analog input response time is usually ≤ 10ms, and digital input response time is ≤ 1ms, which can quickly capture changes in on-site signals.

-Working power supply: Generally using DC 24V power supply, compatible with PLC system power supply, the allowable fluctuation range of power supply voltage is usually DC 18-30V, suitable for industrial site power environment.

-Working temperature range: -25 ℃ to+60 ℃, suitable for harsh industrial environments such as high and low temperatures, ensuring stable operation under different working conditions.

-Protection level: The protection level of the module body is generally IP20 (after panel installation), suitable for installation environment inside the control cabinet.

Installation and wiring specifications

1. Installation requirements

-Installation location: It should be installed in a well ventilated control cabinet without severe vibration or strong electromagnetic radiation, avoiding direct sunlight and liquid splashing.

-Installation method: Standard DIN rail installation should be used, with at least 5mm gap between modules to ensure good heat dissipation.

-Grounding requirements: The grounding terminal of the module should be reliably grounded, with a grounding resistance of ≤ 4 Ω, and form an equipotential connection with the system grounding grid to enhance anti-interference ability.

2. Wiring specifications

-Power wiring: Strictly distinguish the positive and negative poles of the power supply (usually "+" connected to DC 24V, "-" connected to DC 0V) to avoid module damage caused by reverse connection.

-Signal wiring: Analog input signals need to use shielded twisted pair cables, with the shielding layer grounded at one end; Digital input signals should be kept away from power cables to avoid electromagnetic interference. When wiring, it is necessary to correspond to the module channel number to ensure correct signal access.

-Communication wiring: If the module needs to communicate with the PLC master station, communication cables should be connected according to the system communication protocol (such as PROFINET, EtherNet/IP, etc.) to ensure stable communication links.

Applicable scenarios and maintenance points

1. Applicable scenarios

This module, with its high stability and precision, is widely used in various industrial automation fields. Typical scenarios include:

-Manufacturing industry: Collecting parameters such as temperature, pressure, and flow rate of production line equipment, such as automotive parts production and electronic component assembly.

-Process industry: Monitoring process parameters in industries such as chemical, petroleum, and metallurgy to achieve precise control over the production process.

-Energy industry: collection of equipment status signals in the fields of electricity, new energy, etc., such as monitoring of operating parameters of generator sets, current and voltage collection of photovoltaic power stations, etc.

-Infrastructure: Collecting signals such as liquid level and flow rate in fields such as water treatment and sewage treatment to ensure stable operation of infrastructure.

2. Maintenance points

-Regular inspection: Regularly check whether the module wiring is loose and whether the terminals are oxidized every month. If there are any abnormalities, they should be dealt with in a timely manner.

-Cleaning and maintenance: Clean the module surface and heat dissipation holes every quarter to remove dust and debris and avoid affecting heat dissipation.

-Troubleshooting: If there is a signal abnormality in the module, the module status can be checked through the PLC diagnostic function. First, check the wiring and on-site equipment, and then determine whether the module is faulty.

-Firmware upgrade: According to the official firmware update information released by ABB, timely upgrade the module firmware to improve module performance and compatibility.

Precautions

-Before module installation and wiring, the system power must be disconnected to avoid module damage or personnel safety accidents caused by live operation.

-It is strictly prohibited to use beyond the rated parameter range of the module, such as overvoltage, overcurrent, etc., to avoid damaging the internal circuit of the module.

-When replacing modules, it is necessary to use products of the same model and version to ensure compatibility with the PLC system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-