ABB 500CMP04 HE401314/0001 1MRB150051R1 is a high stability power module designed specifically for industrial automation control systems. It belongs to the ABB AC 500 series PLC matching power supply product system, and its core function is to provide continuous and reliable DC power supply for PLC controllers, I/O modules, and other low-voltage electronic devices in the system. It is the "energy core" that ensures the stable operation of automation systems. It has a wide input voltage range, efficient conversion, comprehensive protection mechanism, and compact structural design, and is widely suitable for various industrial scenarios such as manufacturing production lines, process control, and intelligent warehousing that require strict power supply reliability and stability.

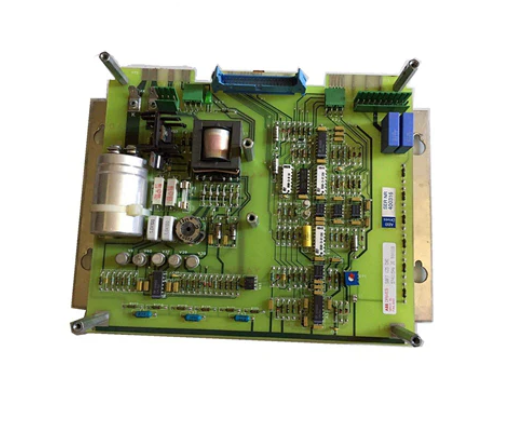

ABB 500CMP04 HE401314/0001 1MRB150051R1 power module

Basic overview of module

ABB 500CMP04 HE401314/0001 1MRB150051R1 is a high stability power module designed specifically for industrial automation control systems. It belongs to the ABB AC 500 series PLC matching power supply product system, and its core function is to provide continuous and reliable DC power supply for PLC controllers, I/O modules, and other low-voltage electronic devices in the system. It is the "energy core" that ensures the stable operation of automation systems. It has a wide input voltage range, efficient conversion, comprehensive protection mechanism, and compact structural design, and is widely suitable for various industrial scenarios such as manufacturing production lines, process control, and intelligent warehousing that require strict power supply reliability and stability.

Core functions and features

2.1 Wide range input and stable output

This module adopts a wide AC input design, which can adapt to the power grid standards of different countries and regions, effectively resisting the impact of power grid voltage fluctuations on output. The output terminal can provide precise and stable DC voltage (typically DC 24V, subject to actual model parameters), with low output voltage ripple coefficient, which can avoid problems such as controller calculation errors and I/O module signal distortion caused by unstable power supply. At the same time, the module has excellent load adjustment rate, and the output voltage can still remain within a very small fluctuation range when the load current dynamically changes from the minimum to the rated value, ensuring the stable operation of various equipment in the system.

2.2 Efficient Energy Saving and Low Loss Design

The module adopts advanced switching power supply technology, with a power conversion efficiency of over 90% (specific values need to refer to the official manual). Compared with traditional linear power supplies, it significantly reduces energy loss, not only reducing the power consumption in industrial sites, but also reducing the module's own heating and extending its service life. In addition, the module is equipped with an intelligent heat dissipation structure, and through optimized heat sink design and temperature adaptive heat dissipation strategy, it reduces the use of vulnerable components such as fans while ensuring heat dissipation effect, thereby improving the reliability of the system.

2.3 Comprehensive Security Protection Mechanism

To cope with the complex power supply risks in industrial sites, the module integrates multiple safety protection functions, including overcurrent protection, overvoltage protection, short circuit protection, over temperature protection, and input undervoltage protection. When faults such as load short circuit, abnormal increase in output voltage, module temperature exceeding the standard, or low input voltage occur, the module will quickly activate the protection mechanism to avoid damage to itself and backend equipment by cutting off the output or limiting the current. At the same time, some models support fault self recovery function, which can automatically restore normal power supply after troubleshooting, reducing manual intervention costs.

2.4 Convenient integration and operation features

The module adopts a standard DIN rail installation method compatible with the AC 500 series PLC, with a compact structure and small space occupation. It can be seamlessly integrated with other I/O modules, controllers, etc. in the same control cabinet, simplifying the system layout and installation process. The front of the module is equipped with clear status indicator lights (such as power input indicator light, normal output indicator light, fault alarm indicator light, etc.), and operation and maintenance personnel can intuitively judge the working status of the module through the indicator lights, quickly locate power supply faults, and improve operation and maintenance efficiency.

Key technical parameters

Input voltage range

AC 85-264V

Wide input, compatible with most global industrial power grid standards

Input frequency range

47-63Hz

Compatible with common frequency fluctuations in industrial power grids

output voltage

DC 24V ±0.5V

Accurate output to meet the power supply requirements of PLC and I/O modules

Rated output current

4A (typical value)

Reasonably allocate power supply resources based on system load requirements

Output Ripple and Noise

≤50mVp-p

Low ripple output ensures stable operation of sensitive electronic devices

conversion efficiency

≥ 90% (under rated load)

Efficient and energy-saving, reducing operating costs

Load adjustment rate

≤±1%

High stability of output voltage during load changes

Working temperature range

-20℃ ~ +60℃

Adapt to harsh industrial environments with high and low temperatures

protection function

Overcurrent, Overvoltage, Short Circuit, Over Temperature, Undervoltage Protection

Comprehensive guarantee of module and backend device security

Installation method

35mm standard DIN rail installation

Compatible installation with AC 500 series PLC and I/O modules

Installation and wiring specifications

4.1 Installation Requirements

The module should be installed in a well ventilated control cabinet free of dust, oil, and corrosive gases, avoiding direct sunlight. During installation, it is necessary to maintain a heat dissipation gap of at least 10mm with other heating devices (such as high-power contactors and frequency converters) to ensure smooth air circulation. If there is a strong electromagnetic interference source (such as a high-frequency frequency converter) inside the control cabinet, the power module should be physically isolated from the interference source or shielded to prevent electromagnetic interference from affecting the stability of the module operation. The installation surface should be firm and flat to avoid vibration causing loose module wiring or damage to internal components.

4.2 Wiring precautions

-Input wiring: Strictly distinguish the phase line (L), neutral line (N), and grounding (PE) of the input terminal. The grounding terminal must be reliably grounded, and the grounding resistance should be ≤ 4 Ω to enhance the anti-interference ability and safety of the module; It is recommended to use copper core wires with a cross-sectional area of ≥ 1.5mm ² for the input circuit, and equip them with 10A fuses for overcurrent protection.

-Output wiring: The output terminals (+V, - V) should be correctly connected to the positive and negative poles of the backend load, and reverse connection is strictly prohibited to avoid damage to the load equipment or module; The output circuit should select wires with appropriate cross-sectional area based on the total load current to ensure sufficient current carrying capacity and reduce line voltage drop.

-Wiring specifications: Input and output lines should be wired separately to avoid parallel laying and prevent interference signals from the output side from coupling to the input side; All wiring terminals must be securely fastened in place to avoid contact resistance caused by virtual connections, which can lead to local heating or unstable voltage.

Typical application scenarios

1. Manufacturing production line: Provides centralized power supply for AC 500 series PLC controllers, digital I/O modules, analog I/O modules, and sensors (such as photoelectric sensors and proximity switches) to ensure the continuous and stable operation of the automation control process of the production line, suitable for scenarios such as automotive parts manufacturing and electronic component assembly.

2. Process control field: In process control systems in industries such as chemical and petrochemical, power is supplied to PLC control systems and control circuits of on-site actuators (such as solenoid valves, regulating valve positioners) to ensure precise control of process parameters such as temperature, pressure, and flow.

3. Intelligent warehousing system: Provides reliable power supply for PLC control systems, conveyor drive modules, scanning equipment, and positioning sensors in warehousing logistics, ensuring efficient operation of automatic sorting, handling, and storage processes for goods.

4. Municipal automation equipment: applied in municipal engineering such as sewage treatment and water supply systems, it supplies power to various electronic devices in the on-site PLC control cabinet, ensuring the automatic start stop and operation monitoring of water pumps, valves and other equipment.

Maintenance and troubleshooting

6.1 Key points of daily maintenance

Regularly (recommended once a month) inspect the appearance of the module, clean the dust on the surface of the module and the heat sink, and ensure good heat dissipation; Check whether the input and output wiring terminals are loose or oxidized. If there is oxidation, it needs to be sanded with fine sandpaper and re tightened; Observe the working status through the module status indicator lights, record the changes in the indicator lights, and provide a basis for fault prediction. In addition, it is necessary to regularly check the input voltage and output voltage of the module to ensure that the voltage values are within the normal range.

6.2 Common faults and solutions

Normal input but no output voltage

1. Internal power circuit failure of the module; 2. Output terminal load short circuit triggers overcurrent protection; 3. Module temperature too high triggers over temperature protection

1. Disconnect all loads and power on the module separately. If there is still no output, repair or replace the module; 2. Check the output circuit and load, eliminate short circuit faults, and restart the module; 3. Improve ventilation conditions, lower ambient temperature, and restart after the module cools down

Unstable output voltage or excessive ripple

1. Excessive fluctuations in input voltage; 2. Excessive or unbalanced output load; 3. Aging of internal filtering capacitors in the module

1. Install a voltage regulator or UPS on the input side; 2. Reduce or redistribute the load to ensure that it does not exceed the rated output current of the module; 3. Contact professionals to replace aging filter capacitors

The fault indicator light is constantly on

1. Input voltage is too high or too low; 2. Output short circuit or overcurrent; 3. Internal module malfunction

1. Check the input voltage to ensure it is within the module's adaptation range; 2. Check the output circuit and load, eliminate short circuits and overcurrent problems; If the fault still exists after the above problems are eliminated, the module needs to be replaced

Severe module heating

1. The load current exceeds the rated value; 2. Insufficient heat dissipation gap or poor ventilation; 3. Internal heat dissipation structure failure of the module

1. Reduce the load current to ensure that it does not exceed the rated output; 2. Adjust the installation position of the module, increase the heat dissipation gap, and improve the ventilation of the control cabinet; 3. Contact after-sales service for repair or module replacement

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-