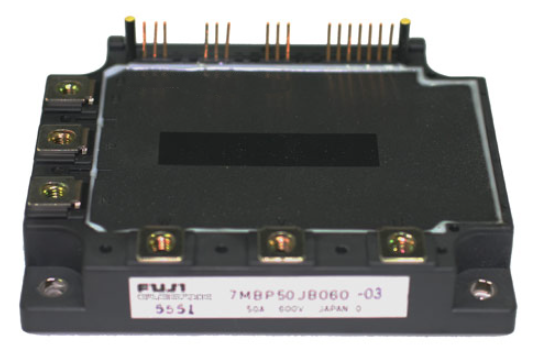

FUJI A50L-001-0266 # N is a programmable logic control (PLC) module designed specifically for industrial automation scenarios, belonging to Fuji Electric's industrial control product line. This module has the core advantages of high reliability, stable computing performance, and good compatibility, and is widely used in manufacturing production line control, equipment automation driving, and industrial process supervision, providing precise and efficient logic control solutions for various industrial systems.

FUJI A50L-001-0266 # N Programmable Logic Control Module

Basic information of module

-Product Model: A50L-001-0266 # N

-Manufacturer: Fuji Electric

-Product category: Programmable Logic Control (PLC) dedicated module

-Applicable scenarios: Medium and low voltage industrial automation systems, production line logic control, equipment linkage control, data acquisition and feedback systems

-Core positioning: As the core control unit or functional expansion module of the PLC system, it undertakes logical operations, instruction execution, and external device communication coordination tasks

Core functions and performance characteristics

1. Efficient logical operation capability

This module is equipped with a Fuji specific industrial grade processor, which has high-speed instruction execution capability. The basic logic instruction execution speed can reach microseconds, and it can quickly respond to complex control requirements. Supporting multiple programming methods such as ladder diagrams, structured text (ST), and functional block diagrams (FBD), adapting to the programming habits of different engineers, and compatible with Fuji standard PLC programming software (such as FUJI MICREX-F series programming tools), reducing development and debugging costs.

2. Stable hardware performance

Adopting industrial grade anti-interference hardware design, it has strong electromagnetic compatibility (EMC), which can resist the adverse environmental effects such as voltage fluctuations, electromagnetic radiation, dust, humidity, etc. in industrial sites. The working temperature range covers -10 ℃~60 ℃, meeting the environmental requirements of most industrial scenarios. The module integrates overcurrent and overvoltage protection circuits internally, effectively ensuring the safe operation of itself and connected devices.

3. Rich interfaces and scalability

The module is equipped with standard digital input/output interfaces, which can directly connect external devices such as sensors and actuators. It also supports common industrial communication protocols such as RS-485 and Ethernet, making it easy to exchange data with upper computers (such as SCADA systems, touch screens) and other control modules, achieving centralized monitoring and distributed control of the system. In addition, this module can be flexibly adapted to control requirements of different scales by expanding I/O modules, analog modules, etc. through Fuji dedicated bus.

4. Convenient maintenance and diagnostic functions

The integrated status indicator lights on the surface of the module (such as power lights, running lights, fault lights) can intuitively reflect the working status of the module. The remote diagnosis function can be achieved through programming software, which can monitor the operating parameters and fault information of the module in real time (such as communication interruption, input/output abnormalities), and support fault alarm and historical data recording, greatly reducing the difficulty and time cost of on-site maintenance.

Typical application scenarios

1. Manufacturing production line control: used for automotive parts production, electronic component assembly and other production lines to achieve automated process switching, equipment linkage control and production counting statistics, improving production efficiency and product qualification rate.

2. Mechanical equipment automation: adapted to CNC machine tools, packaging machinery, printing machinery and other equipment, achieving precise execution of equipment actions (such as feed, cutting, packaging) through logical control, ensuring stable operation of equipment.

3. Industrial process supervision: In industries such as chemical and food processing, sensors are used to collect process parameters such as temperature, pressure, and liquid level, and automatic adjustment and safety interlock control of the production process are achieved through logical operations.

4. Energy management system: used for controlling energy equipment such as factory distribution systems and photovoltaic inverters, achieving reasonable energy distribution, load monitoring, and abnormal protection, and reducing energy consumption.

Precautions for use

-The module installation must strictly follow the installation specifications provided by Fuji Electric, ensuring a firm installation, good heat dissipation, and avoiding close placement with strong electromagnetic interference sources (such as frequency converters).

-Before wiring, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the module. Reverse wiring is strictly prohibited to avoid module damage.

-When programming, it is necessary to write programs reasonably according to actual control requirements, avoid logical conflicts, and reserve necessary fault handling logic to improve the reliability of the system.

-Regularly clean and inspect the modules, promptly remove surface dust, check for loose wiring terminals, and ensure long-term stable operation of the modules.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-