The core competitiveness of DMC9940 lies in its deeply optimized hardware architecture and software algorithms, which can be summarized as follows:

The controller supports up to 8-axis synchronous control, with inter axis linkage delay as low as microseconds, and can achieve complex trajectory control such as linear interpolation, arc interpolation, spline curve interpolation, etc. The positioning accuracy reaches ± 0.1 pulse equivalent, meeting the strict precision requirements of precision machining, semiconductor packaging and other scenarios. Its built-in PID+feedforward control algorithm can effectively suppress load disturbances and mechanical vibrations, ensure the smoothness of the motion process, and reduce positioning errors.

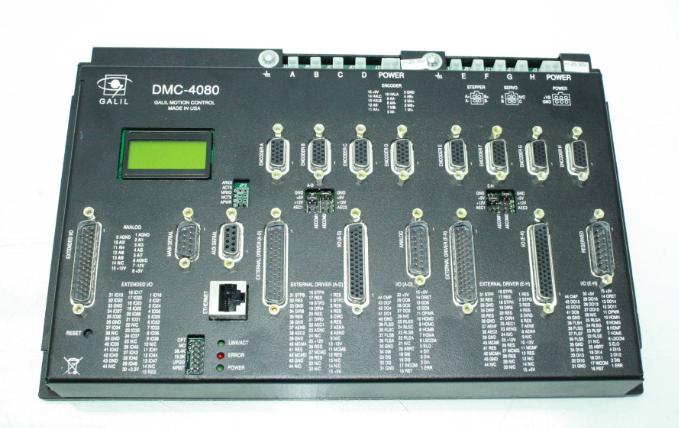

GE GALIL DMC9940 Advanced Motion Controller

Core feature: Empowering complex motion control requirements

The core competitiveness of DMC9940 lies in its deeply optimized hardware architecture and software algorithms, which can be summarized as follows:

1. Multi axis collaboration and high-precision control

The controller supports up to 8-axis synchronous control, with inter axis linkage delay as low as microseconds, and can achieve complex trajectory control such as linear interpolation, arc interpolation, spline curve interpolation, etc. The positioning accuracy reaches ± 0.1 pulse equivalent, meeting the strict precision requirements of precision machining, semiconductor packaging and other scenarios. Its built-in PID+feedforward control algorithm can effectively suppress load disturbances and mechanical vibrations, ensure the smoothness of the motion process, and reduce positioning errors.

2. Powerful computing and expansion capabilities

Equipped with a high-performance 32-bit microprocessor with a computing speed of up to 100MHz, it can simultaneously process multiple sets of motion instructions and I/O signals, supporting complex logic judgment and real-time data processing. Rich expansion interfaces, including industrial communication interfaces such as EtherCAT, Modbus TCP, RS-485, as well as digital input/output interfaces and analog interfaces, can easily interface with servo motors, sensors, human-machine interfaces (HMI) and other peripherals, adapting to different automation system architectures.

3. Flexible programming and debugging experience

Support GALIL exclusive G language programming, with concise and easy to understand syntax, and compatible with IEC 61131-3 standard structured text (ST), ladder diagram (LD) and other programming methods, reducing engineers' learning and development costs. The accompanying GalilTools debugging software provides a visual operation interface, which can monitor the axis motion status in real time, modify control parameters, record motion trajectories, and facilitate quick troubleshooting and optimization of control solutions.

4. High reliability and industrial grade protection

Adopting industrial grade components and modular design, the working temperature range is wide up to -40 ℃~85 ℃, which can adapt to harsh industrial environments. Equipped with multiple protection functions such as overcurrent, overvoltage, overheating, and position deviation, it can respond to abnormal situations in a timely manner, protect the safety of controllers and peripherals, reduce equipment failure risks, and enhance production continuity.

Key technical parameters: Quantitative performance advantages

Number of controlled axes

Up to 8 axes, supporting synchronous linkage between axes

Pulse output frequency

Single axis maximum 2MHz, supports differential signal output

positioning accuracy

± 0.1 pulse, supporting electronic gear and electronic cam functions

communication interface

EtherCAT (supporting CoE protocol) Modbus TCP、RS-485、USB 2.0

I/O interface

16 digital inputs (optoelectronic isolation), 16 digital outputs (relays/transistors), 4 analog inputs (0-10V)

power supply voltage

DC 24V ± 10%, power consumption ≤ 15W

working environment

Temperature: -40 ℃~85 ℃, humidity: 10%~90% (no condensation), protection level IP30

Typical application scenarios: covering the needs of multiple industries

With its comprehensive performance, DMC9940 has been widely used in multiple fields and has become the core control unit of automation equipment

1. Precision manufacturing and processing

In CNC engraving machines, laser cutting machines, PCB drilling machines and other equipment, DMC9940 achieves multi axis collaborative motion control to ensure the accuracy and efficiency of cutting, engraving, drilling and other processes, reduce material waste, and improve product qualification rate. For example, in the field of laser cutting, its high-speed interpolation function can ensure the smoothness of curve cutting and meet the processing requirements of complex shaped workpieces.

2. Robots and automated production lines

Used for motion control of multi joint robots, palletizing robots, and assembly robots, achieving precise positioning and smooth movement of robot arms. On an automated production line, multiple devices such as conveyor belts, robotic arms, and testing equipment can be coordinated to achieve full process automation control of loading, processing, testing, and unloading, thereby improving the production line's capacity and stability.

3. Semiconductor and Electronic Manufacturing

In equipment such as semiconductor wafer handling, chip packaging, and electronic component placement machines, the high-precision control capability of DMC9940 ensures precise grasping and placement of small components, with positioning errors controlled at the micrometer level, meeting the ultimate requirements of the semiconductor industry for process accuracy. At the same time, its high reliability can ensure 24-hour continuous operation of equipment, adapting to the high production capacity needs of semiconductor factories.

4. Medical and research equipment

In the motion control unit of medical imaging equipment (such as CT, MRI), biological sample detection equipment, and laboratory automation platform, DMC9940 ensures the accuracy and repeatability of equipment operation with stable performance and precise control, providing reliable support for medical diagnosis and scientific research experiments.

Product Advantage: Why choose DMC9940?

Compared with similar motion controllers, the core advantages of DMC9940 are reflected in three dimensions:

-Performance balance: Balancing high precision, high speed, and multi axis collaboration capabilities, without compromising between performance indicators, suitable for complex scene requirements;

-Usability: Flexible programming methods and visual debugging tools reduce development and maintenance costs, shorten equipment launch cycles;

-Compatibility and Scalability: With rich communication interfaces and modular design, it can be compatible with different brands of servo motors, sensors, and other peripherals, making it easy to upgrade and modify the system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-