ABB 3BSE008062R1 PM633 is a high-performance processor module designed for high-end industrial automation scenarios, belonging to the ABB Advant OCS and AC800M control system core component series. It focuses on high-speed computation of complex control algorithms and centralized control of large-scale I/O devices. It adopts a multi-core processor architecture and redundant design, which can be seamlessly integrated into ABB distributed control systems (DCS). It is designed to provide logic control, process regulation, and safety interlocking functions for large-scale production equipment in industries such as petrochemicals, power, metallurgy, etc. With microsecond level computing speed, high reliability redundancy, and extensive protocol compatibility, it has become the "brain core" of automation control for large-scale industrial equipment.

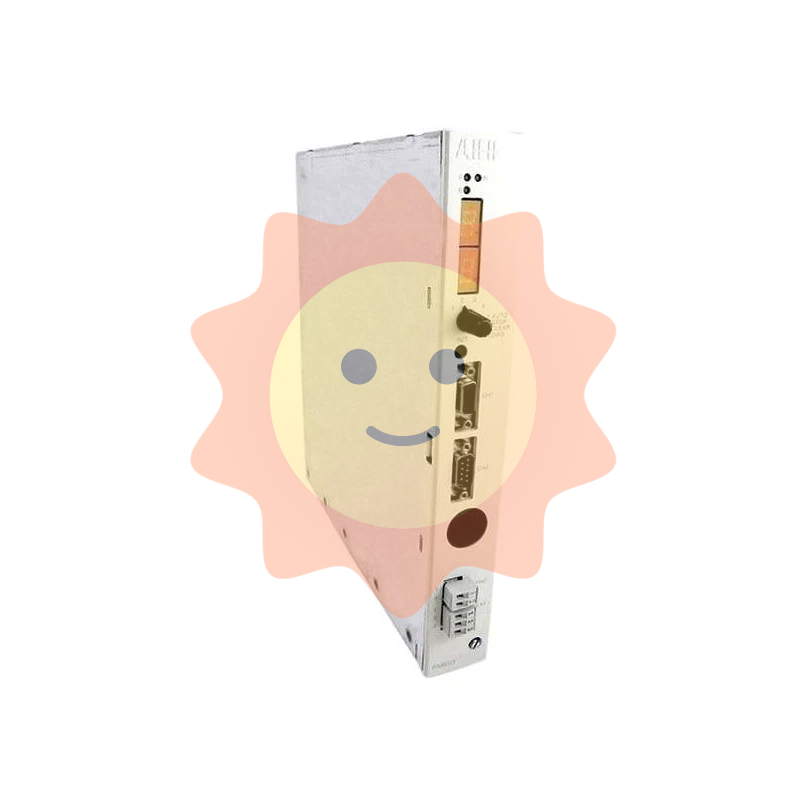

ABB 3BSE008062R1 PM633 Processor Module

Product Overview

ABB 3BSE008062R1 PM633 is a high-performance processor module designed for high-end industrial automation scenarios, belonging to the ABB Advant OCS and AC800M control system core component series. It focuses on high-speed computation of complex control algorithms and centralized control of large-scale I/O devices. It adopts a multi-core processor architecture and redundant design, which can be seamlessly integrated into ABB distributed control systems (DCS). It is designed to provide logic control, process regulation, and safety interlocking functions for large-scale production equipment in industries such as petrochemicals, power, metallurgy, etc. With microsecond level computing speed, high reliability redundancy, and extensive protocol compatibility, it has become the "brain core" of automation control for large-scale industrial equipment.

Specification parameters

1. Core operations and control parameters

Processor configuration

Dual core 32-bit RISC processor with a clock speed of 800MHz and built-in hardware floating-point unit (FPU)

Memory configuration

512MB DDR3 SDRAM (running memory), 256MB Flash (program storage), supporting up to 1GB memory expansion

Control cycle

Basic control cycle ≤ 1ms, high-speed logic operation cycle as low as 100 μ s

I/O expansion capability

Supports up to 256 I/O submodules, capable of connecting digital, analog, and special function modules, with a total of 8192 I/O points

2. Hardware and communication parameters

Communication interface

2 x Ethernet (100/1000Mbps, supports redundancy), 1 x RS-485 (Modbus RTU), 1 x PROFIBUS DP master interface

Redundant design

Support processor redundancy (1:1 hot standby), communication redundancy, power redundancy, with a switching time of ≤ 100ms

Environmental tolerance

Working temperature 0 ° C to 60 ° C, storage temperature -40 ° C to 85 ° C, relative humidity 5% -95% (no condensation), anti vibration level IEC 60068-2-6

Physical specifications

Size 160 × 130 × 50mm, weight 0.8kg, supports ABB AC800M standard rack installation, protection level IP20

3. Certification and compatibility

Certification: CE (EN 61131-3), UL 61010-1, ATEX explosion-proof certification, compliant with IEC 61508 SIL 2 safety standard

System compatibility: compatible with ABB Advant OCS and AC800M DCS systems, compatible with third-party I/O modules (compliant with PROFIBUS DP standard)

Software compatibility: Supports ABB Control Builder M V5.1 and above versions, supports ladder diagram (LD), structured text (ST), function block diagram (FBD), and sequential function diagram (SFC) programming

Performance characteristics

Multi core high-speed computing: With a dual core 800MHz processor paired with a hardware FPU, the computational efficiency of complex control algorithms (such as MPC model predictive control and PID cascade control) is improved by 60% compared to a single core processor. It can simultaneously process real-time acquisition and control of over 1000 I/O signals.

Full dimensional redundancy guarantee: triple redundancy design for processor, communication, and power supply, with a switching time of ≤ 100ms in 1:1 hot standby mode, ensuring uninterrupted operation of large production equipment in case of module failure, and system availability reaching 99.999%.

Large scale I/O control: A single module supports 8192 point I/O signal access, compatible with multiple types of signals such as digital, analog, and pulse signals. It can be extended to remote I/O stations through PROFIBUS DP, adapting to the decentralized control needs of complex scenarios such as large petrochemical plants and thermal power plants.

Safety and Compliance: Complies with the IEC 61508 SIL 2 safety standard, supports safety interlock logic programming, and can achieve emergency shutdown (ESD) and fault safety control functions, meeting the safety regulatory requirements of high-risk industries such as petrochemicals and coal mines.

Flexible protocol adaptation: Dual Gigabit Ethernet supports industrial protocols such as Modbus TCP, EtherNet/IP, PROFINET, etc. The PROFIBUS DP master interface can directly interface with third-party devices such as frequency converters and smart meters without the need for additional protocol converters, reducing system integration complexity.

Working principle

This module operates based on the high-end control logic of "data acquisition operation processing instruction output redundant backup", with the core process as follows:

Data collection stage: Receive on-site data (such as temperature, pressure, flow rate, valve opening) uploaded by distributed I/O modules through PROFIBUS DP and Ethernet interfaces. After signal isolation and verification, store it in the high-speed cache area with a data update cycle of ≤ 1ms

Calculation processing stage: Dual core processors work together, with the main core executing preset control logic (such as PID regulation and interlock logic), and the sub core responsible for data preprocessing and communication management; Hardware FPU accelerates mathematical operations, quickly solves complex control models, and generates control instructions.

Instruction output stage: Control instructions are transmitted to the I/O module through redundant communication links to drive actuators (such as regulating valves, frequency converters, contactors) to act, while the instruction execution status is transmitted back to the processor to form a control loop; If the main module fails, the redundant module immediately takes over and outputs instructions, and there is no data loss during the switching process.

Redundancy and Diagnostic Stage: The redundancy management unit monitors the real-time operating status of the main/backup modules (such as processor load, memory usage, communication links), and triggers a hot backup switch when the main module encounters an abnormality; The built-in self diagnostic function can detect module hardware faults (such as memory errors, communication port faults), and upload fault information to the operation and maintenance system through Ethernet.

Precautions

1. Installation specifications

It must be installed in the designated slot of ABB AC800M standard rack, and the rack must be reliably grounded (grounding resistance ≤ 1 Ω); Reserve at least 50mm of heat dissipation space around the module, and equip the control cabinet with a forced air cooling system (wind speed ≥ 1m/s) to avoid performance degradation caused by high temperature.

Communication cables should use shielded twisted pair cables (PROFIBUS DP) or shielded Category 6 Ethernet cables, with both ends of the shielding layer grounded; Redundant communication links need to be wired independently to avoid parallel laying with power cables (spacing ≥ 30cm) and reduce electromagnetic interference.

2. Operation and maintenance

Before the first use, it is necessary to complete processor redundancy configuration, I/O mapping, and control logic download through Control Builder M software to ensure that the parameters of the main/backup modules are consistent; Suggest enabling the "online backup" function to backup programs and configuration files in real-time.

Check the module operation status (processor load, memory usage, redundancy switching times) through the ABB System 800xA monitoring platform every month, and it is recommended to control the load rate below 70%; Perform a redundancy switch test every quarter to verify the availability of backup modules.

3. Safety protection

Before installation and maintenance, it is necessary to cut off the module power supply, rack power supply, and associated I/O circuit power supply, wait for the capacitor to fully discharge (at least 10 minutes), and wear an anti-static wristband to prevent static electricity from damaging the processor chip.

When used in explosion-proof areas, it is necessary to cooperate with ABB explosion-proof control cabinets (compliant with ATEX standards), and I/O modules must not be plugged or unplugged during module operation; Software upgrades need to be carried out during production equipment downtime or low load periods, and control programs and historical data need to be backed up before the upgrade.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-