ABB L110-24-1 is a compact control module designed for low-voltage industrial control scenarios, belonging to ABB's low-voltage automation core component series. It focuses on precise control and status monitoring of small and medium-sized loads. It adopts standardized modular design and can be seamlessly integrated into ABB low-voltage control cabinets and third-party automation systems. It is designed to provide stable control signals and power support for low-voltage equipment such as relays, small contactors, sensors, etc. With wide voltage adaptation, high reliability protection, and convenient installation characteristics, it has become a key control unit in scenarios such as machine tools, automated production lines, and small process equipment.

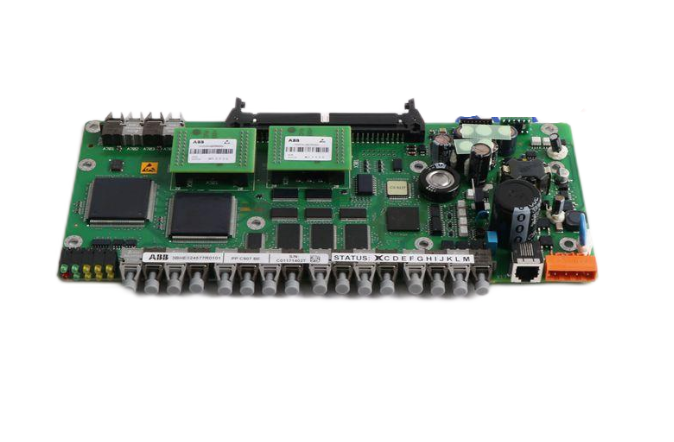

ABB L110-24-1 Industrial Control Module

Product Overview

ABB L110-24-1 is a compact control module designed for low-voltage industrial control scenarios, belonging to ABB's low-voltage automation core component series. It focuses on precise control and status monitoring of small and medium-sized loads. It adopts standardized modular design and can be seamlessly integrated into ABB low-voltage control cabinets and third-party automation systems. It is designed to provide stable control signals and power support for low-voltage equipment such as relays, small contactors, sensors, etc. With wide voltage adaptation, high reliability protection, and convenient installation characteristics, it has become a key control unit in scenarios such as machine tools, automated production lines, and small process equipment.

Specification parameters

1. Core control and power supply parameters

Control signal output

8-channel independent digital control output, supporting dry contact/wet contact mode switching

Scope of power supply adaptation

Input voltage: 24V DC (wide range adaptation 18-30V DC), output voltage: 24V DC constant output

Load driving capability

Each control output has a maximum current of 1A, and the total output current is ≤ 5A (suitable for small electromagnetic loads)

Signal response speed

Control instruction received to output action delay ≤ 5ms, status feedback response time < 2ms

2. Hardware and environmental parameters

Communication interface

1 × RS-485 interface (supporting Modbus RTU protocol), realizing data exchange with upper computer/PLC

Status monitoring

Support monitoring of load current and module operating temperature for each output, with overload/over temperature status feedback

Environmental tolerance

Working temperature -10 ° C to 55 ° C, storage temperature -40 ° C to 80 ° C, relative humidity 5% -95% (no condensation)

Physical specifications

Size 90 × 60 × 35mm, weight 0.2kg, supports DIN rail installation (35mm standard rail), protection level IP20

3. Certification and compatibility

Certification: CE (EN 61131-2), UL 508 industrial safety certification, compliant with IEC 61010-1 low voltage control equipment standard

System compatibility: compatible with mainstream low-voltage control systems such as ABB AC500 small PLC and Siemens S7-1200

Software compatibility: Supports parameter configuration through Modbus protocol, compatible with ABB Automation Builder and third-party Modbus configuration software

Performance characteristics

Low voltage load precise adaptation: 24V DC constant output and 1A/channel driving capability, specially designed for low voltage loads such as relays and small contactors, to avoid load misoperation caused by voltage fluctuations, suitable for machine tool auxiliary circuits and small actuator control scenarios.

Flexible communication and monitoring: Remote control command issuance and operation status uploading can be achieved through the RS-485/Modbus protocol, with real-time monitoring of output current and module temperature for each channel, making it easy for the upper computer to grasp the load operation status and warn potential faults in advance.

Multiple safety protections: Built in overload protection for each output (1A current limit), module over temperature protection (triggered at 65 ° C), and power reverse protection. When the load is short circuited or the module overheats, the corresponding output is automatically cut off and a fault signal is fed back to avoid equipment damage.

Compact installation and low power consumption: With a compact size of 90 × 60 × 35mm, it occupies only 60% of the space in the control cabinet compared to traditional control modules; Typical working power consumption ≤ 3W, low heat design reduces control cabinet heat dissipation pressure, suitable for high-density installation scenarios.

Convenient operation and maintenance design: supports online configuration of output modes and protection thresholds through upper computer software, without the need for on-site disassembly and debugging; The front of the module is equipped with LED indicator lights (power/communication/output status of each channel), making the fault status visually visible and improving troubleshooting efficiency by 50%.

Working principle

This module operates based on the low-voltage control logic of "instruction reception logic processing load driving state feedback", with the core process as follows:

Instruction reception stage: Receive control instructions issued by the upper computer or PLC through the RS-485 interface (such as an output "on/off" signal), and after Modbus protocol parsing and data verification, transmit them to the core control unit.

Logic processing stage: The embedded MCU performs logical judgment on the control instructions, combines the current module temperature and the load current status of each channel, confirms that there are no abnormalities, generates the corresponding output channel drive signal, and activates the state monitoring circuit.

Load driving stage: The driving circuit converts logical signals into power signals and supplies power to loads such as relays and small contactors through output terminals; When the load current exceeds 1A, the current limiting protection circuit is activated to prevent overload damage to the load.

State feedback stage: The current sampling resistor real-time collects the output current of each channel, and the temperature sensor monitors the core temperature of the module. After digital processing, the data is transmitted back to the upper computer through the RS-485 bus, forming a closed-loop link of "control monitoring feedback".

Precautions

1. Installation specifications

Adopting 35mm standard DIN rail for vertical installation, with at least 15mm gap reserved between modules to ensure air circulation and heat dissipation; Avoid being in close proximity to strong interfering equipment such as frequency converters and high-power motors (with a distance of ≥ 30cm) to reduce the impact of electromagnetic interference.

When wiring, distinguish between power input, control output, and communication lines: the power line uses 0.75mm ² copper core wire, the control output line uses 0.5-1mm ² copper core wire according to the load current, and the communication line uses shielded twisted pair (shielded layer single ended grounding).

2. Operation and maintenance

Before the first use, the module address and communication baud rate (default 9600bps) need to be configured through Modbus configuration software to ensure that they match the communication parameters of the upper computer/PLC; Simultaneously calibrate the accuracy of current monitoring (error ≤ ± 5%).

Check the module operation data through the upper computer every month, focusing on whether the load current of each channel is stable (to avoid approaching the upper limit of 1A for a long time); Check the tightness of the wiring terminals every quarter, clean the dust on the surface of the module, and ensure smooth heat dissipation.

3. Safety protection

Before installation and maintenance, the module power supply and associated load power supply must be cut off, and the capacitor must be discharged (at least 2 minutes) before operation to prevent electric shock or load misoperation.

It is recommended to install a 5A fast fuse at the power input end to prevent external power short circuits from damaging the module; When used in humid environments, moisture-proof devices should be installed on the control cabinet to prevent the internal components of the module from becoming damp and failing.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-