YASKAWA CACR-HR10BB is a high-performance AC servo drive launched by Yaskawa Electric (YASKAWA), belonging to the HR series servo drive product camp, designed specifically for small and medium power servo motors. Its core positioning is to achieve efficient and stable operation of servo motors through precise current, speed, and position control, and it is widely used in industrial automation equipment that requires high precision in motion control. This driver integrates advanced vector control technology and reliable hardware design from Yaskawa Electric, with advantages such as fast response speed, high control accuracy, and strong anti-interference ability. It can seamlessly adapt to Yaskawa's corresponding servo motor models and provide excellent motion control solutions for equipment.

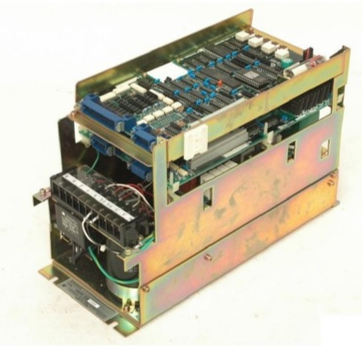

YASKAWA CACR-HR10BB servo drive

YASKAWA CACR-HR10BB is a high-performance AC servo drive launched by Yaskawa Electric (YASKAWA), belonging to the HR series servo drive product camp, designed specifically for small and medium power servo motors. Its core positioning is to achieve efficient and stable operation of servo motors through precise current, speed, and position control, and it is widely used in industrial automation equipment that requires high precision in motion control. This driver integrates advanced vector control technology and reliable hardware design from Yaskawa Electric, with advantages such as fast response speed, high control accuracy, and strong anti-interference ability. It can seamlessly adapt to Yaskawa's corresponding servo motor models and provide excellent motion control solutions for equipment.

Core performance parameters

The YASKAWA CACR-HR10BB servo drive has undergone precise tuning in terms of performance parameters, balancing power output and control accuracy. The key parameter details are as follows:

-Power parameters: Adopting three-phase AC power supply mode, rated input voltage is AC 200V~230V, allowable voltage fluctuation range is ± 10%, suitable for industrial standard power supply environment; The rated current of the main circuit is 1.7A, and the control circuit is powered by DC 24V with a rated current of 0.2A, ensuring stable power supply for the drive and control circuits.

-Adaptive motor: Designed specifically for Yaskawa 100W level servo motors, the compatible motor models include SGMGH series and other corresponding power specification products, supporting a rated motor speed of 3000r/min, which can fully utilize the motor's power performance and speed regulation potential, and achieve precise torque and speed control.

-Control performance: Adopting advanced vector control algorithms, it has three control modes: position control, speed control, and torque control, which can be flexibly switched according to different application scenarios; High position control accuracy, supporting multiple position command input methods such as pulse/direction, CW/CCW, etc., with a pulse response frequency of up to 500kpps, ensuring positioning accuracy under high-speed motion; Wide speed control range, low steady-state speed fluctuation, excellent low-speed stability, and can effectively suppress vibration and noise during low-speed operation.

-Hardware specifications: Adopting a compact body design, the external dimensions are suitable for installation in standard industrial control cabinets, making it easy to integrate systems in limited spaces; Equipped with comprehensive input and output interfaces, including motor power interface, encoder signal interface, digital I/O interface, and communication interface, to meet diverse system connection requirements; Built in high-efficiency heat dissipation module, excellent heat dissipation performance, can adapt to long-term continuous operation conditions.

-Environmental adaptability: The working temperature range is 0 ℃~40 ℃ (without freezing or condensation), and the storage temperature range is -20 ℃~60 ℃; The working humidity is 35%~85% RH (without condensation), which can adapt to the environmental conditions of most industrial production sites; Having excellent resistance to electromagnetic interference and passing strict electromagnetic compatibility (EMC) certification, it can effectively resist electromagnetic interference generated by high-power equipment, frequency converters, and other industrial sites.

Core functional features

The YASKAWA CACR-HR10BB servo drive relies on Yaskawa Electric's mature servo control technology, highlighting reliability, precision, and ease of use in its functional design. The core features are as follows:

-High precision vector control and smooth operation: Using fully closed-loop vector control technology, the stator current component of the motor can be accurately controlled, achieving independent control of torque and magnetic flux, greatly improving torque response speed and control accuracy; Built in micro step drive function effectively reduces vibration and noise during motor operation by refining current control pulses. Especially under low-speed operating conditions, it can still maintain excellent stability, ensuring the machining accuracy and operational stability of the equipment.

-Complete protection and fault diagnosis functions: equipped with comprehensive safety protection mechanisms, including overcurrent protection, overload protection, overvoltage protection, undervoltage protection, overheating protection, motor overload protection, and encoder fault protection, etc; When abnormal working conditions occur, the driver can quickly cut off the output and trigger an alarm, while recording the fault code and fault log, making it easier for staff to accurately locate the fault point and shorten the troubleshooting time; Equipped with fault self recovery function, some minor faults can automatically reset after the working conditions are restored to normal, improving the continuity of system operation.

-Flexible control modes and parameter configuration: supports seamless switching between position, speed, and torque control modes, which can be set through panel buttons, external signals, or upper computer software to adapt to different motion control requirements; Provide rich configurable parameters, including PID parameters, electronic gear ratios, torque limits, speed limits, etc. Engineers can accurately calibrate and optimize control performance based on equipment characteristics and process requirements; Support parameter backup and recovery functions, facilitating batch device parameter replication and system maintenance.

-Excellent compatibility and scalability: Using standardized communication interfaces and control signals, it can easily integrate seamlessly with various PLCs, motion controllers, touch screens, and other upper level devices, supporting multiple control methods such as pulse commands, analog commands, and bus control; Equipped with extended I/O interfaces, external sensors, actuators, and other devices can be connected according to actual needs to enhance the system's scalability; Compatible with multiple series of servo motors from Yaskawa Electric, while also supporting third-party servo motors that meet standards (requiring parameter matching), reducing the difficulty of system integration.

-Energy saving and easy-to-use design: Built in automatic torque compensation and energy-saving operation functions, can automatically adjust the output torque according to load changes, reduce energy consumption under light load conditions, and meet industrial energy-saving requirements; Equipped with an intuitive operation panel and LED status indicator lights, it can display the real-time operation status, control mode, and fault information of the driver, making it easy to operate and debug on site; Support online debugging and monitoring functions, and real-time collection of driver operating parameters (such as current, voltage, speed, position, etc.) through dedicated software, enabling online modification and optimization of parameters.

Typical application scenarios

YASKAWA CACR-HR10BB servo drive is widely used in the high-end industrial automation field with high requirements for motion control accuracy and stability, thanks to its precise control performance, reliable operation performance, and flexible adaptability. Typical application scenarios are as follows:

-In the field of precision machining, it is used in conjunction with Yaskawa 100W servo motors in small precision machine tools, CNC engraving machines, laser cutting machines, and other equipment to achieve precise position and speed control of the spindle or feed axis, ensuring the dimensional accuracy and surface smoothness of the machined parts; By achieving fast torque response and stable low-speed operation performance, the processing efficiency and product qualification rate of the equipment are effectively improved.

-Automated assembly and handling equipment: In electronic component assembly machines, small robotic arms, automatic loading and unloading devices, etc., responsible for driving the actuator to complete precise grasping, handling, assembly and other actions; With high-precision positioning function, it ensures the accuracy and consistency of component assembly, and adapts to different action process requirements through flexible control mode switching.

-Packaging and printing machinery: used in small packaging machines, label printers, bill printing machines, and other equipment to control the movement of feeding and cutting mechanisms, achieving precise conveying and fixed length cutting of materials; Through stable speed control and synchronous control functions, the accuracy of packaging and printing is ensured, avoiding problems such as material deviation and uneven cutting.

-Medical devices and laboratory equipment: In small medical devices (such as medical syringe filling equipment, small diagnostic equipment) and laboratory precision instruments (such as sample automatic samplers, precision measuring equipment), their high precision, low noise, and high reliability are utilized to achieve precise mechanical motion control, ensuring the stability of equipment operation and detection/treatment accuracy.

-Textile and light industry machinery: used in small textile machines, embroidery machines, knitting machines and other equipment to control yarn conveying, stitch movement and other mechanisms, ensuring the quality and texture consistency of textile products through precise speed and position control; Suitable for long-term continuous operation of equipment, with reliable heat dissipation and protection functions, reducing equipment failure rate.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-