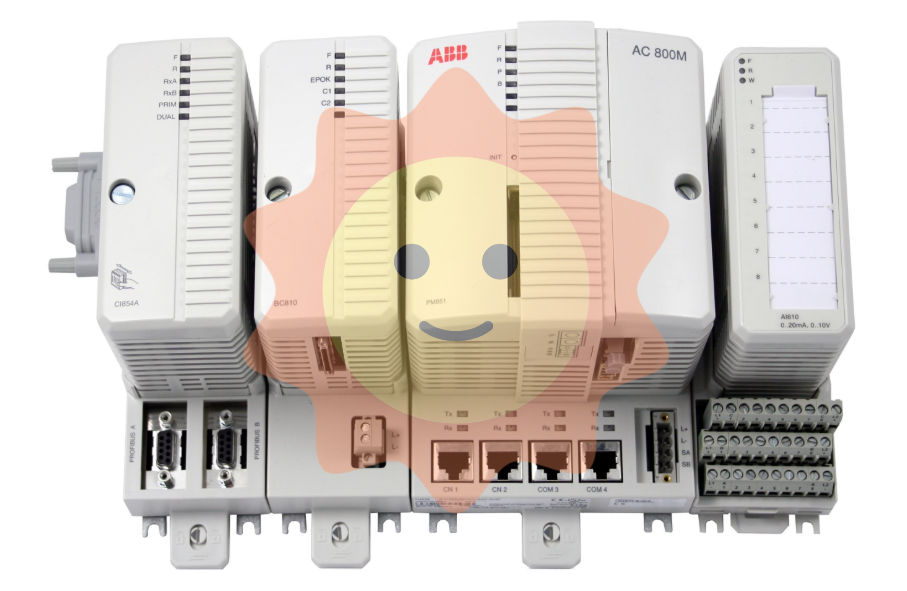

ABB CI873K01 (order number: 3BSE058899R1) is a high-performance Ethernet/IP interface module designed specifically for industrial automation control systems, belonging to the I/O expansion module category of ABB AC 800M controller series. The core function of this module is to build a high-speed data communication bridge between the AC 800M controller and external devices and control systems that support Ethernet/IP protocols, achieving industrial grade real-time data exchange and device collaborative control. It is widely used in industrial scenarios such as power, chemical, metallurgical, and manufacturing industries that require strict communication stability and real-time performance.

ABB CI873K01 3BSE058899R1 Ethernet/IP interface module

Basic overview of module

ABB CI873K01 (order number: 3BSE058899R1) is a high-performance Ethernet/IP interface module designed specifically for industrial automation control systems, belonging to the I/O expansion module category of ABB AC 800M controller series. The core function of this module is to build a high-speed data communication bridge between the AC 800M controller and external devices and control systems that support Ethernet/IP protocols, achieving industrial grade real-time data exchange and device collaborative control. It is widely used in industrial scenarios such as power, chemical, metallurgical, and manufacturing industries that require strict communication stability and real-time performance.

As a key communication component in ABB's automation solutions, the CI873K01 module, with its high reliability, flexible configuration capabilities, and strong protocol compatibility, can seamlessly integrate into complex industrial control networks, providing core support for users to build efficient and stable automation control architectures.

Core functions and advantages

2.1 High speed Ethernet/IP communication

The module is fully compatible with Ethernet/IP industrial protocols and supports communication modes based on Producer/Consumer, which enables efficient data distribution and avoids bandwidth waste in traditional point-to-point communication. Its communication speed can reach up to 100Mbps, supporting full duplex communication mode, effectively reducing data transmission delay, ensuring real-time interaction between control instructions and device status data, and meeting the strict requirements for response speed in industrial control.

2.2 Flexible Network Adaptation Capability

The module is equipped with a standard RJ45 Ethernet interface and supports Auto Negotiation function. It can automatically match the communication speed (10Mbps/100Mbps) and communication mode (full duplex/half duplex) of the connected devices without manual configuration, greatly simplifying the on-site installation and commissioning process. At the same time, it supports Ethernet/IP VLAN (Virtual Local Area Network) function, which can logically partition the network, improve network security and data transmission stability, and avoid communication interference between different devices.

2.3 Powerful integration and expansion capabilities

The CI873K01 module can seamlessly interface with the local bus of ABB AC 800M controller (such as PROFIBUS DP or ABB dedicated I/O bus) without the need for additional switching devices, achieving fast interconnection between the controller and devices in Ethernet/IP networks. In addition, the module supports connecting multiple Ethernet/IP slave devices, such as smart sensors, actuators, frequency converters, human-machine interfaces (HMI), etc., and can manage up to hundreds of node devices, meeting the expansion needs of medium to large industrial control systems.

2.4 High reliability and industrial grade protection

The module adopts industrial grade hardware design and has a wide temperature working range (usually -20 ℃~+60 ℃), which can adapt to harsh industrial site environments such as high temperature, low temperature, and high humidity changes. At the same time, the module has a complete fault diagnosis and fault tolerance mechanism, supporting communication fault alarm, module status monitoring and other functions. When there are network interruptions, equipment failures and other problems, it can send alarm information to the controller in a timely manner, which facilitates the operation and maintenance personnel to quickly locate and solve the problem, and improves the overall reliability of the system.

2.5 Convenient Configuration and Maintenance

The module supports centralized configuration through ABB Control Builder M engineering software, and operation and maintenance personnel can intuitively set key parameters such as communication parameters, device mapping relationships, and data transmission cycles in the software, without the need to debug each device on site. At the same time, the module supports online diagnostic function, which can monitor the working status, communication traffic, fault information, etc. of the module in real time through software, achieve remote maintenance and management, and reduce operation and maintenance costs.

Key technical parameters

Basic Information

Model/Order Number

CI873K01 / 3BSE058899R1

Communication parameters

communication protocol

Ethernet/IP (IEEE 802.3)

communication rate

10Mbps/100Mbps adaptive

interface type

1 RJ45 Ethernet interface

Power parameters

power supply voltage

Usually 24V DC (18V~30V DC wide voltage range)

power consumption

Typical value is about 5W, maximum not exceeding 8W

environmental parameters

Operating Temperature

-20℃~+60℃

Storage temperature

-40℃~+85℃

relative humidity

5%~95% (no condensation)

mechanical parameters

Installation method

DIN rail installation (35mm standard rail)

Dimensions (length x width x height)

Approximately 100mm x 150mm x 80mm (subject to actual product)

compatibility

Adaptive controller

ABB AC 800M series controller

Typical application scenarios

4.1 Industrial production line automation control

In production lines such as automobile manufacturing and electronic equipment assembly, the CI873K01 module can achieve Ethernet/IP communication between the AC 800M controller and equipment such as frequency converters, robots, conveying equipment, and detection instruments in the production line. Real time transmission of control instructions and equipment operation data ensures the coordinated work of various links in the production line, improving production efficiency and product quality.

4.2 Chemical Engineering and Process Control

In process industries such as chemical and petrochemical, modules can be connected to intelligent devices such as pressure transmitters, temperature sensors, flow sensors, valve actuators, etc. on site, transmitting real-time collected process parameters to the AC 800M controller, and issuing control instructions from the controller to on-site equipment to achieve precise control of equipment such as reactors, storage tanks, pipelines, etc., ensuring the stability and safety of the production process.

4.3 Power System Automation

In power scenarios such as substations and power plants, modules can achieve communication between AC 800M controllers and power monitoring equipment (such as relay protection devices, smart meters, switchgear), collect real-time power parameters (voltage, current, power, etc.) and equipment status information, realize remote monitoring, fault diagnosis, and automated scheduling of the power system, and improve the operational reliability of the power system.

4.4 Smart Factory and Industry 4.0 Applications

In the construction of smart factories, the CI873K01 module serves as a connecting node between industrial control networks and enterprise information networks. It can upload equipment data and production data from the workshop site to MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning) systems through Ethernet/IP networks, achieving transparent management of the production process and providing data support for production scheduling, quality traceability, and cost control of enterprises, helping to implement Industry 4.0.

Installation and commissioning precautions

-The module installation must strictly follow the DIN rail installation specifications to ensure a secure installation and avoid interface looseness or module damage caused by vibration; The installation location should be far away from strong electromagnetic interference sources (such as high-power motors and transformers), and shielding measures should be taken if necessary.

-When wiring, it is necessary to confirm that the power supply voltage matches the rated voltage of the module to avoid module burnout caused by overvoltage; Ethernet cables should use industrial grade shielded twisted pair cables (such as CAT5e or CAT6), and the cable length should comply with Ethernet communication specifications (maximum transmission distance of 100 meters). If the distance exceeds 100 meters, industrial switches should be used for relaying.

-Before configuration, it is necessary to ensure that the Control Builder M software version is compatible with the module firmware version to avoid configuration failure caused by version mismatch; During the configuration process, it is necessary to accurately set the IP address, subnet mask, gateway, and other network parameters of the device to ensure that the module, controller, and other devices are in the same network segment.

-During the debugging phase, it is important to focus on testing communication stability, which can be monitored through software for indicators such as data transmission delay and packet loss rate; Simultaneously simulate communication faults (such as disconnecting cables, shutting down slave devices), and verify whether the fault alarm function of the module is normal.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-