ABB DSAO120A (order number 3BSE018293R1) is a high-performance advanced analog output board designed specifically for the signal output requirements of industrial automation control systems. Its core function is to accurately convert digital control signals into analog signals and output them to on-site devices such as actuators, regulating valves, and frequency converters, achieving precise adjustment of key parameters such as temperature, pressure, flow rate, and liquid level in industrial production processes. This module is widely compatible with mainstream distributed control systems (DCS) such as ABB Advant OCS and 800xA, and is a core component for ensuring stable and precise control of industrial production processes, especially suitable for complex industrial scenarios that require strict control accuracy and response speed.

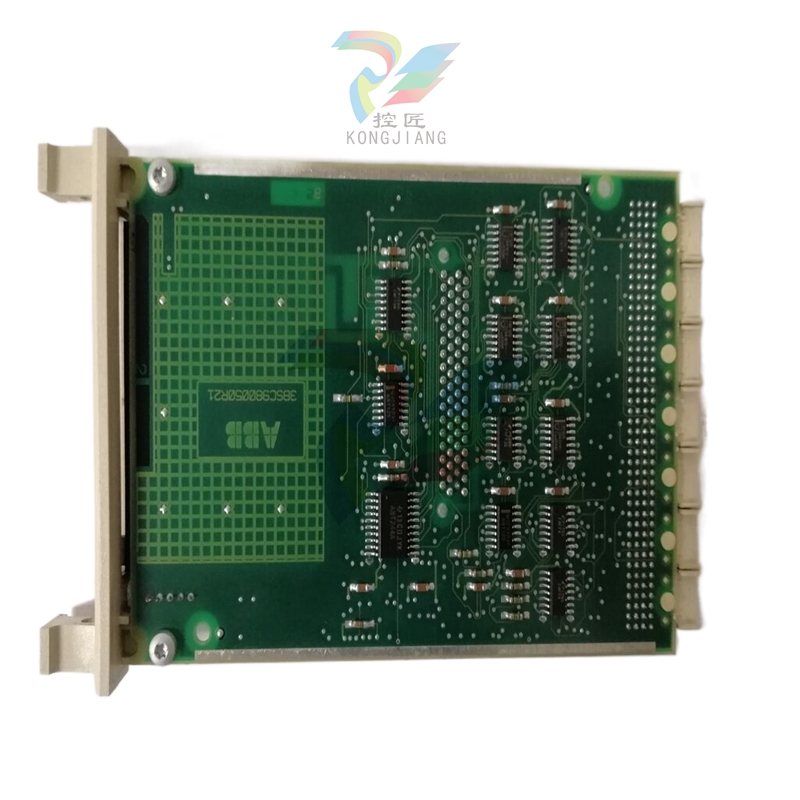

ABB DSAO120A 3BSE018293R1 Advanced Analog Output Board

Product core positioning

ABB DSAO120A (order number 3BSE018293R1) is a high-performance advanced analog output board designed specifically for the signal output requirements of industrial automation control systems. Its core function is to accurately convert digital control signals into analog signals and output them to on-site devices such as actuators, regulating valves, and frequency converters, achieving precise adjustment of key parameters such as temperature, pressure, flow rate, and liquid level in industrial production processes. This module is widely compatible with mainstream distributed control systems (DCS) such as ABB Advant OCS and 800xA, and is a core component for ensuring stable and precise control of industrial production processes, especially suitable for complex industrial scenarios that require strict control accuracy and response speed.

Key technical parameters

1. Basic specifications

Model identification

DSAO120A 3BSE018293R1

The standard order number corresponds uniquely to the model, ensuring the accuracy of product traceability

Dimensions (W × H × D)

140mm×180mm×75mm

Compliant with standard industrial cabinet installation dimensions and compatible with other ABB I/O modules

Weight

About 0.8kg

Including the weight of the metal shell, balancing structural strength and installation convenience

Protection level

IP20

Suitable for indoor cabinet installation, effectively preventing dust and solid foreign objects from entering

Power supply mode

24V DC ±15%

Supports wide voltage input, adapts to industrial field voltage fluctuation environment, requires external independent power supply

2. Electrical and output characteristics

Output channels: 8 independent analog output channels, supporting simultaneous control of multiple field devices to improve system control efficiency

Output signal type: compatible with 4-20mA DC current signal and 0-10V DC voltage signal. The two signal types can be switched through software configuration to meet the signal requirements of different field devices

Output accuracy: Current signal accuracy ± 0.1% FS (full range), voltage signal accuracy ± 0.2% FS, ensuring high accuracy of control signals

Output load capacity: maximum current output load of 750 Ω, minimum voltage output load of 1k Ω, meeting the load requirements of most industrial actuators

Response time: The signal conversion response time is ≤ 10ms, which can quickly respond to control instructions and ensure the dynamic control performance of the production process

Resolution: 16 bit D/A conversion resolution, achieving fine adjustment of control signals and improving production process control accuracy

3. Environmental adaptability

Working temperature: -25 ° C to 70 ° C, suitable for harsh industrial plant environments such as high and low temperatures

Storage temperature: -40 ° C to 85 ° C, meeting the environmental requirements for long-term inventory and transportation of products

Relative humidity: 5% -95% (no condensation), to avoid problems such as circuit short circuits and component damage caused by humid environments

Anti interference: Complies with the IEC 61000-6-2 industrial anti electromagnetic interference (EMI) standard, has the ability to resist radio frequency interference (RFI), and can stably output control signals in strong electromagnetic radiation and high-frequency interference environments

Vibration and Shock: Capable of withstanding sine vibrations within the frequency range of 5-150Hz with an acceleration of 1g, as well as shocks with a peak acceleration of 10g and a duration of 11ms, suitable for the vibration environment during the operation of industrial field equipment

Core functions and advantages

1. High precision analog signal output and flexible configuration

The module adopts high-precision 16 bit D/A conversion chip and advanced signal conditioning circuit to ensure the high precision and stability of the output signal, meeting the requirements of precision industrial control. At the same time, the signal types (current/voltage) of the 8 output channels can be independently configured through ABB system configuration software, without the need to replace hardware, greatly improving the module's versatility and on-site application flexibility, and reducing equipment selection and inventory costs.

2. Comprehensive fault diagnosis and safety protection

Fault diagnosis function: supports channel level fault diagnosis, can monitor real-time output signal open circuit, short circuit, overload and other fault states, and upload fault information to the DCS system for easy operation and maintenance personnel to quickly locate the fault point

Overcurrent protection: Each output channel is equipped with an overcurrent protection circuit. When the output current exceeds the rated range, the output of that channel is automatically cut off to protect the module and backend actuator from damage

Overvoltage protection: When the power supply voltage is too high, the built-in overvoltage protection component will quickly operate, cutting off the power supply circuit and protecting the internal circuit of the module

Thermal protection: Temperature monitoring components are installed inside the module. When the operating temperature of the module exceeds the safe range, the output power will be automatically reduced or some non critical channel outputs will be cut off to prevent damage to the module due to overheating

3. Convenient system integration and operation management

System compatibility: seamlessly integrated into ABB Advant OCS, 800xA and other DCS systems, supporting data communication with controllers through the system bus. Parameter configuration, status monitoring and fault query can be directly performed at the DCS operator station without the need for additional configuration software

Remote configuration and maintenance: Supports remote configuration and modification of module output channel parameters (such as signal type, range, zero/full range calibration) through the DCS system. At the same time, it can remotely read module working status, channel output values, and fault codes, reducing on-site operation and maintenance workload and improving operation and maintenance efficiency

Status indication: The module is equipped with LED indicator lights on the front, which can intuitively display the module's power status (normal/faulty), overall working status (normal/faulty), and output status of each channel (normal/faulty), making it easy for on-site operation and maintenance personnel to quickly judge the module's operating status

4. High reliability and long-term stable operation

The module adopts industrial grade high reliability electronic components and reinforced PCB board design. After strict environmental adaptability testing (high and low temperature, humidity, vibration, impact, etc.) and long-term aging testing, the mean time between failures (MTBF) exceeds 100000 hours, ensuring the long-term stable operation of industrial production processes, reducing equipment downtime risks and maintenance costs. In addition, the module supports use in conjunction with ABB redundant power supply systems. When the main power supply fails, it can quickly switch to the backup power supply, ensuring uninterrupted analog output signals and guaranteeing the continuity of the production process.

Applicable scenarios and industry applications

1. Core application areas

Process industry: In petrochemical, chemical, metallurgical, pharmaceutical, food and beverage and other process industries, it is used to output control signals to actuators such as regulating valves, frequency converters, solenoid valves, etc., to achieve precise adjustment of key process parameters such as reactor temperature, pressure, pipeline flow rate, liquid level, and material mixing ratio, ensuring the stability of the production process and consistency of product quality. For example, in petrochemical production, the module outputs a 4-20mA current signal to control the opening of the regulating valve in the crude oil pipeline, accurately adjusting the crude oil flow rate; In the pharmaceutical industry, outputting a 0-10V voltage signal controls the speed of the mixing motor frequency converter and adjusts the mixing speed of the materials in the reaction kettle.

Energy and electricity: In the energy field of thermal power plants, nuclear power plants, hydropower stations, etc., it is used to control key equipment such as boiler feedwater regulating valves, steam pressure regulating valves, turbine speed regulating valves, etc., to achieve precise control of parameters such as boiler water level, steam temperature, and turbine speed, ensuring the safe and efficient operation of generator sets. For example, in a thermal power plant, output control signals to regulate the opening of the boiler feedwater control valve and maintain the normal water level of the boiler; Control the opening of the steam regulating valve to stabilize the steam pressure and temperature.

Water treatment industry: In water and sewage treatment plants, it is used to control the speed of the dosing pump, the opening of the inlet valve, the frequency of the aeration fan inverter, etc., to achieve the control of process parameters such as raw water dosage, sewage treatment tank inlet flow rate, aeration intensity, etc., and improve water treatment efficiency and water quality compliance rate. For example, in a sewage treatment plant, the speed of the dosing pump is controlled by module output signals, and the dosage of chemicals is accurately adjusted according to the sewage quality indicators; Control the frequency converter of the aeration fan to regulate the dissolved oxygen concentration in the aeration tank.

Manufacturing industry: In the automation production lines of discrete manufacturing industries such as automobile manufacturing, electronic equipment manufacturing, and mechanical processing, it is used to control the servo drives of robotic arms, the speed regulating valves of production lines, the temperature control modules of heating equipment, etc., to achieve precise control of the motion accuracy, production rhythm, and processing temperature of production equipment, and to improve product processing accuracy and production efficiency. For example, in the production line of automotive parts processing, the output signal controls the servo motor driver of the CNC machine tool to adjust the tool feed speed and processing position; In electronic component welding equipment, control the temperature of the heating module to ensure that the welding temperature meets the process requirements.

2. Typical device connections

Actuators: electric control valves, pneumatic control valves (in conjunction with electric valve positioners), solenoid valves, etc

Drive equipment: frequency converter (used to control motor speed), servo drive (used to control robotic arms, precision transmission mechanisms)

Process control equipment: dosing pump, metering pump, aeration fan, water pump, etc

Temperature control equipment: temperature control module for heating rods and cooling fans

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-