ABB DSRF197 (order number 3BSE019297R1) is a high-performance industrial controller module designed specifically for the core control requirements of industrial automation control systems. Its core function is to receive input signals from various sensors and I/O modules, perform real-time calculations and decisions through built-in control algorithms (such as PID control, logic control, etc.), and then send control instructions to actuators and output modules to achieve precise control and dynamic adjustment of industrial production processes. This module is widely compatible with mainstream distributed control systems (DCS) such as ABB 800xA and Advant OCS. It is a "brain" component that ensures the continuous, stable, and efficient operation of industrial production processes, especially suitable for large-scale industrial scenarios that require extremely high control logic complexity, computing speed, and reliability.

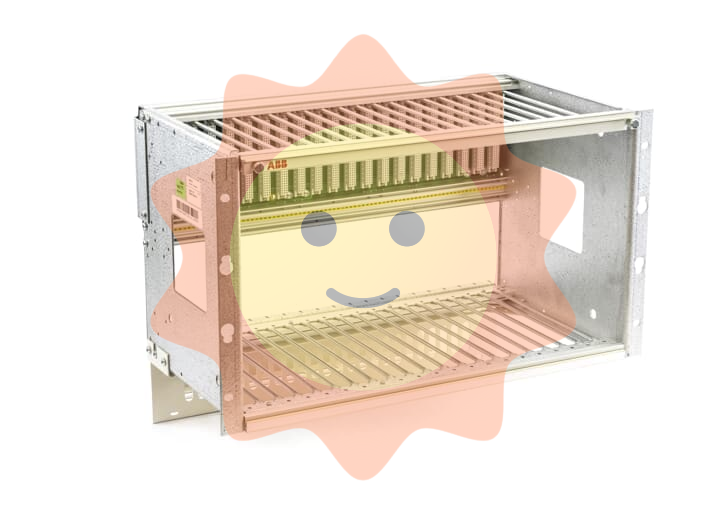

ABB DSRF197 3BSE019297R1 Controller Module

Product core positioning

ABB DSRF197 (order number 3BSE019297R1) is a high-performance industrial controller module designed specifically for the core control requirements of industrial automation control systems. Its core function is to receive input signals from various sensors and I/O modules, perform real-time calculations and decisions through built-in control algorithms (such as PID control, logic control, etc.), and then send control instructions to actuators and output modules to achieve precise control and dynamic adjustment of industrial production processes. This module is widely compatible with mainstream distributed control systems (DCS) such as ABB 800xA and Advant OCS. It is a "brain" component that ensures the continuous, stable, and efficient operation of industrial production processes, especially suitable for large-scale industrial scenarios that require extremely high control logic complexity, computing speed, and reliability.

Key technical parameters

1. Basic specifications

Model identification

DSRF197 3BSE019297R1

The standard order number corresponds uniquely to the model, ensuring product traceability and procurement accuracy

Dimensions (W × H × D)

150mm×200mm×85mm

Compliant with standard industrial cabinet installation dimensions and compatible with ABB series I/O modules and bus modules

Weight

About 1.2kg

Containing metal protective shell weight, balancing structural strength and installation flexibility, suitable for dense layout inside cabinets

Protection level

IP20

Suitable for indoor cabinet installation, effectively preventing dust and solid foreign objects from entering, avoiding external impurities from affecting internal circuits

Power supply mode

24V DC ±10%

Supports wide voltage input, adapts to industrial field voltage fluctuation environment, requires external independent redundant power supply to ensure uninterrupted operation

2. Electrical and computational characteristics

Processor performance: Equipped with a 32-bit industrial grade high-performance microprocessor with a clock frequency of up to 800MHz, supporting multitasking parallel processing and fast computing speed, it can meet the real-time computing needs of complex control logic

Memory configuration: Built in 1GB DDR3 RAM to ensure smooth multitasking operation; Equipped with 8GB industrial grade flash memory (Flash) for storing control programs, parameter configurations, and historical data, supporting data power-off saving

Input/output interface: Provides 16 digital input interfaces (DI, supporting 24V DC signals), 8 digital output interfaces (DO, supporting 24V DC/5A driving capability), and 4 analog input interfaces (AI, supporting 4-20mA DC, 0-10V DC signals), and 2 analog output interfaces (AO, supporting 4-20mA DC signals), which can directly connect basic sensors and actuators, reducing external module dependence

Communication interface: Supports multiple industrial communication protocols, including Profinet, EtherNet/IP, Modbus TCP, ABB dedicated ControlNet, etc., equipped with 2 Gigabit Ethernet ports (RJ45 interface), supports redundant communication, and ensures the stability and real-time performance of data transmission; Simultaneously equipped with one RS485 serial communication port for connecting third-party serial devices

Control cycle: The minimum control cycle can reach 1ms, which can quickly respond to on-site signal changes and achieve dynamic and precise control of the production process, especially suitable for fast response production scenarios (such as high-speed assembly lines, precision machining, etc.)

3. Environmental adaptability

Working temperature: -30 ° C to 75 ° C, suitable for extreme high and low temperature industrial environments, such as outdoor cabinets in northern winter and high-temperature production workshops

Storage temperature: -40 ° C to 85 ° C, meeting the environmental requirements for long-term inventory and long-distance transportation of products, avoiding low-temperature freezing damage or high-temperature aging

Relative humidity: 5% -95% (no condensation), through special PCB board moisture-proof treatment and component selection, to avoid circuit short circuit, corrosion and other problems caused by humid environment

Anti interference: Compliant with IEC 61000-6-2 Industrial Anti Electromagnetic Interference (EMI) standard and IEC 61000-6-4 Anti Radio Frequency Interference (RFI) standard, with electromagnetic shielding design, able to operate stably in strong interference environments such as high-voltage equipment and high-frequency motors, avoiding control errors caused by signal interference

Vibration and impact: able to withstand sinusoidal vibration within the frequency range of 5-200Hz and acceleration of 2g; Capable of withstanding a peak acceleration of 15g and an impact duration of 11ms, suitable for vibration and unexpected impact scenarios during industrial equipment operation (such as equipment start stop, minor collisions, etc.)

Core functions and advantages

1. Powerful control capability and flexible algorithm support

The module is equipped with a rich library of control algorithms, covering classic PID control (supporting PID parameter self-tuning), fuzzy control, logic control (such as ladder diagram and functional block diagram programming), sequential control, etc., which can meet the control needs of different industrial scenarios. Users can customize control logic according to production process requirements through configuration software such as ABB Control Builder M, supporting complex interlocking control, batch control, and process optimization control, and adapting to full scenario applications from simple single machine control to large-scale process industry overall control. At the same time, the module supports online modification of control programs and parameters, allowing configuration updates to be completed without downtime, greatly reducing production interruption time.

2. Comprehensive redundancy design and high reliability

Hardware redundancy: Supports controller redundancy configuration (1+1 redundancy). When the main controller fails, the backup controller can automatically switch within 100ms, achieving "disturbance free switching" and ensuring uninterrupted control process; Simultaneously supporting power redundancy and communication redundancy, from power supply and data transmission to control core, building a full link redundancy system to reduce the risk of single point failure

Fault diagnosis and self-healing: With multi-level fault diagnosis functions, it can monitor the working status of key components such as processors, memory, communication interfaces, and power modules in real time. At the same time, it can diagnose external I/O signal abnormalities (such as signal open circuits and short circuits), and upload fault information (including fault codes and fault locations) in real time to the DCS operator station and operation and maintenance system; Partial minor malfunctions (such as temporary communication interruptions) can be automatically restored through built-in self-healing mechanisms, reducing the need for manual intervention

Industrial level durability: Industrial level high stability electronic components (such as military grade capacitors and anti-aging resistors) and enhanced PCB design (thickened copper foil, anti-corrosion coating) are used. After strict high and low temperature cycling tests, long-term aging tests and electromagnetic compatibility tests, the average trouble free working time (MTBF) exceeds 200000 hours, ensuring long-term continuous operation and reducing equipment maintenance costs

3. Convenient system integration and intelligent operation and maintenance

System compatibility: Seamless integration into ABB 800xA, Advant OCS and other DCS systems, supporting high-speed data exchange with ABB series I/O modules (such as DSDP pulse counting module, DSAO analog output module) and bus modules (such as DSBC bus expansion module) through the system bus, without the need for additional hardware or software adaptation, simplifying system architecture design

Remote monitoring and operation: Support real-time viewing of the controller's working status (such as processor load, memory usage, communication status), control parameters, and historical operating data through DCS system or ABB remote operation platform; It can remotely download control programs, modify parameters, and support remote fault diagnosis and firmware upgrades, reducing the workload of on-site operation and maintenance personnel, especially suitable for the operation and maintenance needs of remote areas or high-risk industrial scenarios (such as chemical parks and nuclear power plants)

Status indication and local operation: The module is equipped with a high-definition LCD display screen on the front, which can intuitively display the controller's operating status, key parameters (such as input/output signal values, control output values), and fault information; Simultaneously set physical operation buttons to support local parameter adjustment and fault reset, facilitating quick troubleshooting by on-site operation and maintenance personnel

4. Data storage and traceability capability

Built in large capacity industrial grade flash memory, supporting storage of up to 1 year of historical operating data (such as key process parameters, equipment status, fault records), with customizable data sampling intervals (minimum 1 second). Users can access historical data through DCS systems or third-party data platforms (such as MES systems) for production process traceability, quality analysis, and process optimization; Simultaneously supporting data encryption storage to prevent the leakage or tampering of critical production data and ensure data security.

Applicable scenarios and industry applications

1. Core application areas

Petrochemical and chemical industry: used in large refineries and chemical plants for reactor temperature/pressure control, distillation tower level/flow regulation, pipeline transportation system interlock control, and other scenarios. For example, in the process of crude oil refining, the module receives signals from temperature sensors and pressure sensors, and uses PID control algorithm to adjust the power of the heating device and the opening of the feed valve to maintain the temperature and pressure inside the reaction kettle stable within the process requirements; Simultaneously implementing the logic control of the Emergency Shutdown System (ESD), when danger signals such as overheating and overpressure are detected, the feeding and heating are quickly cut off to ensure production safety.

Energy and power industry: used in core scenarios such as boiler combustion control, turbine speed regulation, and generator grid connection control in thermal power plants, nuclear power plants, and large wind farms. For example, in thermal power plants, modules receive signals such as boiler water level, steam pressure, and flue gas oxygen content. Through complex coordinated control algorithms, they adjust the water supply, air supply, and fuel supply to achieve efficient and stable operation of the boiler; Simultaneously control the turbine speed control system to maintain stable unit speed and ensure power quality.

Metallurgical industry: used for process control in blast furnace ironmaking, converter steelmaking, and steel rolling production lines in steel mills and non-ferrous metal smelters. For example, in steel rolling production, the module receives signals from the rolling mill pressure sensor and speed sensor, controls the rolling mill pressure and conveying speed, and ensures that the steel thickness and flatness meet quality standards; Simultaneously achieve sequential control of the production line, coordinate the start stop sequence of various equipment (such as heating furnaces, rolling mills, cooling devices), and improve production efficiency.

Water treatment and environmental protection industry: used for full process control of water treatment processes in large sewage treatment plants, water treatment plants, and solid waste treatment plants. For example, in the biochemical treatment process of a sewage treatment plant, the module receives signals from dissolved oxygen sensors and pH sensors, controls the speed of the aeration fan and the amount of chemicals added, maintains microbial activity in the biochemical tank, and improves sewage treatment efficiency; Simultaneously achieve logical control of the sludge dewatering system, coordinating the operation of equipment such as sludge conveying, pressure filtration, and drying.

High end manufacturing industry: used for logic control and motion control in automated production lines for automobile manufacturing, semiconductor production, and precision electronic equipment manufacturing. For example, in the automotive welding production line, the module receives signals from the position sensor of the robotic arm and the welding current sensor, controls the motion trajectory of the robotic arm and welding parameters, and ensures welding quality; Simultaneously achieve cycle control of the production line, coordinate the sequence of actions of various workstation equipment, and improve production cycle efficiency.

2. Typical device connections

Input devices: temperature sensor, pressure sensor, flow sensor, liquid level sensor, displacement sensor, proximity switch, photoelectric switch, etc

I/O modules: ABB DSDP series pulse counting module, DSAO series analog output module, DSDI series digital input module, DSDO series digital output module, etc

Execution equipment: electric control valve, pneumatic control valve, frequency converter (controlling motor speed), servo drive (controlling mechanical arm, precision transmission mechanism), solenoid valve, relay, etc

Communication equipment: industrial switches, bus expansion modules (such as ABB DSBC series), remote I/O stations, etc

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-