The ABB DSQC313 is a highly versatile and reliable automation product designed to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. Engineered for performance, the DSQC313 boasts exceptional technical features that set it apart in the industry.

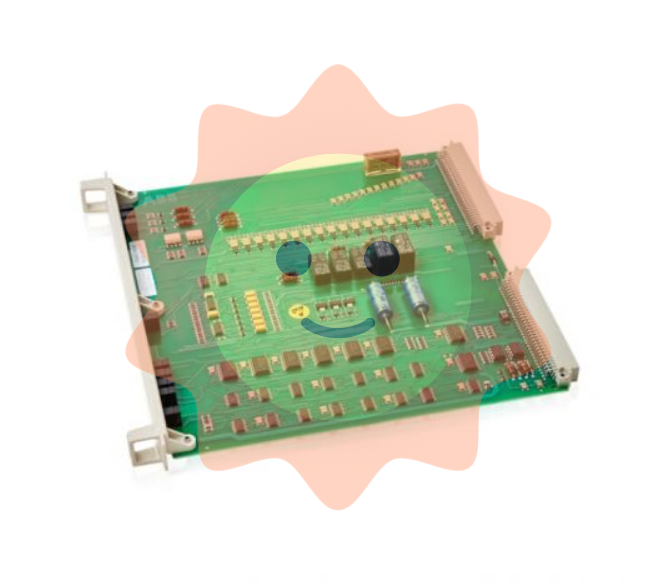

ABB DSQC313 Robot Control Unit

Product Definition

ABB DSQC313 is a high-precision robot control unit designed specifically for ABB industrial robots. As the "brain center" of the robot system, it undertakes the core responsibilities of instruction parsing, motion control, signal interaction, and safety monitoring. This unit is developed based on ABB's mature robot control technology, which can accurately coordinate the joint movements of robots, ensuring high-precision and high stability operations in industrial production scenarios. It is a key bridge connecting the robot body with external control systems, widely applicable to ABB's multiple series of industrial robots, and provides reliable control guarantees for automated production processes.

Core functionality

(1) Motion control function

Multi axis collaborative control: supports synchronous motion control of multiple joints in robots, accurately calculates the motion trajectory, velocity, and acceleration of each joint, and achieves smooth switching of multiple motion modes such as straight lines, arcs, and joints, meeting the trajectory accuracy requirements in complex work scenarios. The positioning accuracy can reach ± 0.01mm level (specific accuracy needs to be combined with the robot body model).

Dynamic trajectory correction: Real time collection of position and velocity feedback signals during robot motion, and real-time correction of trajectory deviations caused by external load changes, mechanical errors, and other factors through built-in dynamic compensation algorithms, ensuring that the robot can maintain stable operational accuracy even after load fluctuations or long-term operation.

(2) Signal interaction and integration function

External device communication: Equipped with rich communication interfaces, including mainstream industrial communication protocol interfaces such as Ethernet, PROFINET, DeviceNet, etc., it can seamlessly interact with external devices such as PLC (Programmable Logic Controller), MES (Manufacturing Execution System), and vision system to support production instruction issuance, job data uploading, and equipment status monitoring, achieving integrated control of automated production lines.

I/O signal management: Integrated with multi-channel digital input/output (I/O) interfaces, it can directly connect peripheral devices such as sensors, solenoid valves, and fixtures to achieve real-time acquisition and control of production site signals, simplify external wiring, and improve system integration efficiency.

(3) Safety control function

Safety Movement Monitoring: Equipped with a built-in safety control module that complies with international safety standards such as EN ISO 13849-1, it can monitor the robot's movement speed and position range in real time. When the robot exceeds the safe working area or has abnormal movement speed, it can quickly trigger a safe shutdown to ensure the safety of operators and equipment.

Fault diagnosis and protection: With comprehensive fault diagnosis functions, it can monitor the internal circuits, communication links, and external device connection status of the control unit in real time. When a fault is detected (such as power supply abnormality, communication interruption, sensor failure), a fault alarm signal will be immediately issued, and corresponding protective measures will be taken (such as emergency shutdown, cutting off output). At the same time, fault information will be stored for subsequent fault investigation and maintenance.

Key technical parameters

Power specification: Input voltage: DC 24V ± 10%; Rated current: maximum 5A

Communication interface: Ethernet interface (10/100Mbps) x 2, PROFINET interface x 1, DeviceNet interface x 1

I/O interface: Digital input: 16 channels (optional PNP/NPN); Digital output: 16 channels (transistor output, maximum 0.5A/channel)

Number of Control Axes: Supports up to 6-axis robot control (expandable to 7-axis, requires specialized modules)

Motion control accuracy: Position repeatability accuracy: ± 0.005mm~± 0.01mm (depending on the robot body model)

Environmental adaptability: Working temperature: 0 ℃~45 ℃; Relative humidity: 20%~80% (no condensation); Protection level: IP20 (panel installation)

Storage capacity: Built in flash memory: 8GB (used for storing programs, parameters, and fault logs)

Applicable scenarios and industry applications

(1) Core applicable scenarios

High precision assembly operations: used in industries such as electronics and automotive components for robot high-precision assembly processes, such as circuit board component welding and automotive component assembly. With its precise motion control capabilities, it ensures that assembly tolerances meet product quality requirements.

Material handling and sorting: In the logistics and food and beverage industries, control robots to complete material grabbing, handling, and sorting operations. Through collaboration with visual systems, precise identification and positioning of materials of different specifications and shapes can be achieved, improving sorting efficiency and accuracy.

Welding and cutting operations: In the automotive and construction machinery industries, robots are controlled to perform arc welding, laser welding, plasma cutting, and other operations. Through dynamic trajectory correction function, the welding path is ensured to be continuous and stable, the cutting edge is smooth, and the welding and cutting quality is improved.

(2) Main application industries

The automotive manufacturing industry includes processes such as body welding, component assembly, and vehicle inspection;

Electronic and electrical industry: circuit board soldering, chip packaging, electronic component sorting and assembly;

Logistics and warehousing industry: material handling, shelf access, and order sorting in intelligent warehouses;

Food processing industry: The grabbing, packaging, and sorting of food materials meet the hygiene standards of the food industry.

Key points for installation and maintenance

(1) Installation specifications

Installation environment preparation: Choose an installation location that is free of dust, corrosive gases, and strong vibrations, avoid close proximity to strong magnetic field equipment (such as large motors and transformers), and ensure that the environmental temperature and humidity meet the technical parameter requirements; The installation table should be flat and stable, with a load-bearing capacity of not less than 5kg (the net weight of the control unit is about 3kg).

Key points of wiring operation: Strictly distinguish power circuits, communication circuits, and I/O circuits according to the wiring diagram to avoid equipment damage caused by wiring errors; The power wiring should ensure that the positive and negative poles are connected correctly and equipped with appropriate fuses (recommended rated current of 5A); Communication cables should use shielded cables to reduce electromagnetic interference, and the shielding layer should be grounded at one end.

System debugging steps: After installation, perform a pre power on inspection to confirm that the wiring is correct and the equipment appearance is not damaged; After power on, connect the control unit through ABB robot teaching pendant or dedicated software for parameter configuration (such as robot model matching, communication protocol settings, I/O address allocation); After completing the parameter configuration, conduct a no-load trial run to test whether the robot's various axis movements are normal and whether signal interaction is smooth.

(2) Daily maintenance and troubleshooting

Daily maintenance matters:

Regularly check the status of the control unit panel indicator lights every week to confirm that the power, communication, and I/O signal indicator lights are displaying normally;

Clean the surface and ventilation openings of the control unit every month to prevent dust accumulation from affecting heat dissipation;

Backup the programs and parameters within the control unit through dedicated software every quarter to prevent data loss;

Every year, tighten and inspect the wiring terminals of the control unit to prevent poor contact caused by loose wiring.

Product advantages and selection suggestions

(1) Core advantages

High reliability: Using industrial grade components and redundant design, after rigorous environmental adaptability testing and lifespan testing, the mean time between failures (MTBF) can reach over 50000 hours, ensuring long-term stable operation.

Strong usability: Supports parameter configuration and debugging through ABB robot teaching pendant or dedicated software, with an intuitive and easy to understand interface, simple operation process, and reduced operating threshold for technical personnel.

Wide compatibility: It can adapt to multiple series of industrial robots such as ABB IRB 120, IRB 2600, IRB 4600, etc., and supports integration with mainstream brands of PLC and vision systems to meet the needs of different automation systems.

(2) Selection suggestions

According to the number of robot axes, if controlling a robot with 6 or fewer axes, the DSQC313 control unit can be directly selected; To control a 7-axis robot, an additional ABB dedicated expansion module is required.

According to communication requirements, if the automation system adopts PROFINET communication protocol, priority can be given to choosing DSQC313 (standard PROFINET interface); If other communication protocols are required, they can be implemented through an extension module.

Selection based on homework accuracy: For high-precision homework scenarios (such as electronic component assembly), a high-precision robot body should be used, and dynamic trajectory correction function should be enabled in the control unit to ensure that the homework accuracy meets the standard.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-