DSQC346U is a servo driven rectifier unit developed by ABB specifically for industrial robots, belonging to the S4C+controller supporting component system, with a core model of 3HAB8101-13. This product is not an independent robot control unit, but focuses on the power supply and motion control adaptation of servo motors. It is mainly used for single axis drive control of ABB IRB series industrial robots. Through rectification and drive signal processing, it achieves precise motor start stop, speed adjustment, and torque control. Its import originates from the United States and is often used as a core spare part for robot servo systems, widely used in the maintenance and upgrading of existing S4C+controller robots.

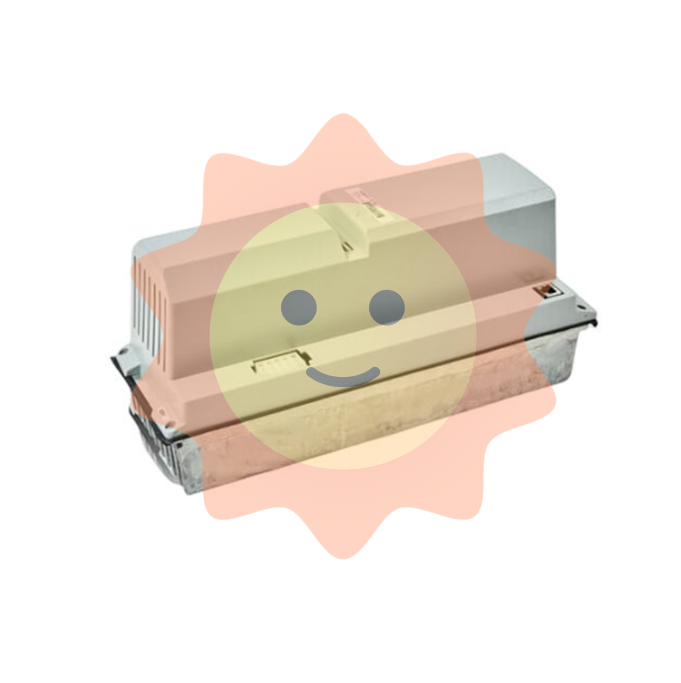

ABB DSQC346U Robot Control Unit

Product Overview

DSQC346U is a servo driven rectifier unit developed by ABB specifically for industrial robots, belonging to the S4C+controller supporting component system, with a core model of 3HAB8101-13. This product is not an independent robot control unit, but focuses on the power supply and motion control adaptation of servo motors. It is mainly used for single axis drive control of ABB IRB series industrial robots. Through rectification and drive signal processing, it achieves precise motor start stop, speed adjustment, and torque control. Its import originates from the United States and is often used as a core spare part for robot servo systems, widely used in the maintenance and upgrading of existing S4C+controller robots.

Specifications

1. Electrical parameters

Input voltage adaptability: Adopting a broadband design, it is compatible with 380V ± 5% voltage fluctuations and adapts to the characteristics of domestic industrial power grids without the need for additional voltage regulation equipment.

Rectification efficiency: The conversion efficiency of the internal rectification module is ≥ 92%, reducing energy loss, minimizing equipment heating, and extending service life.

Output stability: DC bus voltage ripple ≤ 5%, providing stable power for servo motors and ensuring motor operation accuracy.

2. Details of Physical and Installation Parameters

Installation compatibility: Supports standard 19 inch cabinet installation, with installation hole spacing of 250mm × 200mm, and can be co arranged with other S4C+supporting components.

Heat dissipation requirements: Natural heat dissipation design is adopted, and a heat dissipation spacing of ≥ 100mm should be reserved inside the cabinet. It is recommended to install a heat dissipation fan when the ambient temperature exceeds 35 ℃.

3. Supplementary Adaptation Parameters

Motor adaptation range: compatible with ABB Orange series 0.75kW~15kW servo motors, covering the single axis drive requirements of mainstream robots such as IRB 1410 and IRB 2400.

Signal interface: equipped with 2 CAN bus interfaces (for communication with the controller), 1 encoder feedback interface (for receiving motor position signals), and 4 digital input/output interfaces (for status monitoring and control).

Performance characteristics

High reliability design: Made of high-quality industrial grade materials and subjected to rigorous vibration and impact testing, it has an overload tolerance of 30 times the rated tension, with MTBF (mean time between failures) reaching an industrial high level, reducing maintenance costs.

Precision Drive Adaptation: Although there is no direct parameter annotation, its matching S4C+system can achieve high-precision position control and trajectory tracking, indirectly confirming the stability and accuracy of its driving signal.

Strong environmental adaptability: Supports dust-proof and anti-corrosion design, can be installed in enclosed wall mounted cabinets, and adapts to complex industrial environments.

Maintenance convenience: As a standardized spare part, the wiring and installation process is simple, and faulty units can be quickly replaced to ensure the shortest downtime of the production line.

Working principle

The workflow of DSQC346U revolves around three core steps: power conversion, signal interaction, and drive control

Rectification and Conversion Stage: After connecting industrial AC power, the AC power is converted into the DC power required by the servo motor through an internal rectification module, providing basic power guarantee for the motor operation.

Signal interaction stage: Establish real-time communication with S4C+main controller, receive control commands such as position, speed, torque, etc., and provide feedback on motor operating status data (such as current, temperature).

Drive execution stage: Based on control instructions, adjust the output power parameters to drive the servo motor to move along a predetermined trajectory. At the same time, monitor abnormal states through built-in protection mechanisms to achieve fault protection such as overload and overcurrent.

Precautions

Installation environment requirements: The installation should be carried out within the temperature range of 0 ℃~40 ℃, avoiding direct sunlight, humidity (relative humidity ≤ 85%), dusty and smoky environment, and should be horizontally fixed in a well ventilated cabinet without blocking the air vents.

Operating standards: It is strictly prohibited to disassemble or connect wires while powered on; Before cleaning, the power must be turned off and unplugged. Only brushes can be used for dust removal, and liquid contact with the equipment is prohibited.

Maintenance taboos: Non professionals are not allowed to repair or replace parts on their own. In case of malfunction, they must replace them with spare parts of the same model or compatible with revised versions (such as 3HAB8101-13/06A, etc.).

Load limit: Do not operate beyond the rated parameters of the adapted motor to avoid long-term overload that may cause damage to the unit.

Application scenarios

Industrial robot drive: As the single axis servo drive core of ABB IRB series robots (equipped with S4C+controller), it is used for motion control of welding, handling, assembly and other robots.

In the field of metal processing, the Millmate strip tension measurement system is adapted to achieve the coordinated operation of tension control and servo drive in rolling production lines such as steel plates and aluminum foils.

Automated production line: provides precise driving support for robot single machine or multi machine linkage systems in production lines such as automotive parts manufacturing and electronic component assembly.

Equipment maintenance and upgrade: mainly used for replacing spare parts of existing S4C+controller robots to ensure the continuous operation of old production lines.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-