ABB DSU10 is a high-precision control module designed for the industrial automation field, belonging to the ABB process control and motor management core component series. It focuses on multi parameter collaborative control and precise control of equipment status. It adopts a modular design and can be seamlessly integrated into ABB AC500 PLC systems and third-party automation platforms. It is compatible with various types of equipment such as motor drivers, sensors, and actuators. With wide range current adaptation, flexible communication capabilities, and reliable control logic, it has become a key control unit for motor control and process regulation scenarios in industries such as manufacturing and energy.

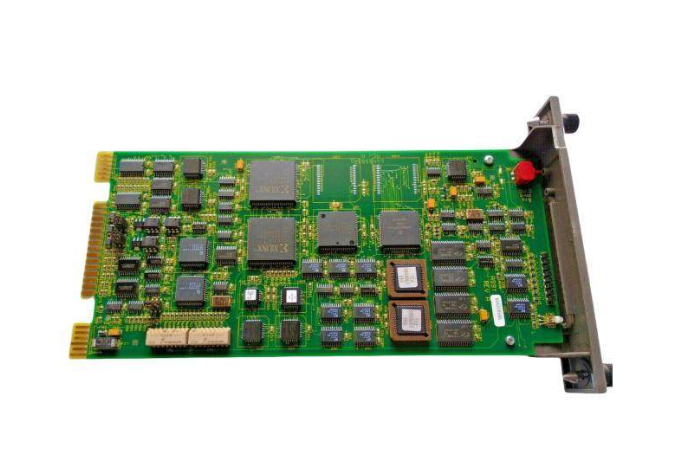

ABB DSU10 Control Module

Product Overview

ABB DSU10 is a high-precision control module designed for the industrial automation field, belonging to the ABB process control and motor management core component series. It focuses on multi parameter collaborative control and precise control of equipment status. It adopts a modular design and can be seamlessly integrated into ABB AC500 PLC systems and third-party automation platforms. It is compatible with various types of equipment such as motor drivers, sensors, and actuators. With wide range current adaptation, flexible communication capabilities, and reliable control logic, it has become a key control unit for motor control and process regulation scenarios in industries such as manufacturing and energy.

Specification parameters

1. Core control parameters

Current control range

Support 0.24A-63.0A wide current regulation, suitable for small and medium-sized motors and load equipment

Voltage adaptation range

230V-400V AC working voltage, compatible with mainstream industrial power grids worldwide (50/60Hz)

Control accuracy

Current regulation error ≤± 0.5% FS, dynamic response time < 10ms

Signal processing capability

Supports 4-channel analog input (0-20mA/0-10V), 2-channel analog output, and 2-channel digital I/O

2. Hardware and environmental parameters

Communication interface

1 × RS-485 interface, supporting Modbus RTU/ASCII protocol, realizing bidirectional data exchange with the upper computer

Power supply specifications

24V DC auxiliary power supply (18-36V DC wide input), with overvoltage and reverse connection protection

Environmental tolerance

Working temperature -10 ° C to 50 ° C, storage temperature -40 ° C to 70 ° C, relative humidity 5% -95% (no condensation)

Physical specifications

Size 160 × 100 × 40mm, weight 0.4kg, supports DIN rail installation, compatible with standard control cabinet layout

3. Certification and compatibility

Certification: CE (EN 61131-2), UL 61010-1 safety certification, compliant with IEC 61800-3 electromagnetic compatibility standard

Software compatibility: compatible with ABB Automation Builder programming software, supporting ladder diagram (LD) and function block diagram (FBD) programming

Performance characteristics

Wide range load adaptation: The current control range of 0.24A-63.0A can cover control requirements from micro actuators to motors below 30kW, without the need to replace modules to adapt to devices of different power levels, reducing system integration costs.

Flexible multi protocol communication: Through Modbus RTU/ASCII protocol, SCADA system and field devices can be directly connected, supporting bidirectional communication of control command download and operation parameter upload, and adapting to the centralized management requirements of distributed control scenarios.

Enhanced protection mechanism: Built in overcurrent, overvoltage, overheating, and stall protection functions. When abnormal load is detected, the protection action can be triggered within 5ms, cutting off the output and triggering an alarm to avoid equipment damage and production accidents.

Convenient operation and maintenance design: supports online parameter configuration and firmware upgrade, built-in self diagnostic function can monitor the real-time status of input and output circuits and modules, and fault information is uploaded through communication interface, reducing troubleshooting time to minutes.

Durability in industrial environment: Using wide temperature industrial grade components and corrosion-resistant enclosures, it can withstand harsh environments such as dust and vibration, and operate stably under high temperature conditions from -10 ° C to 50 ° C, suitable for multiple industrial applications.

Working principle

This module operates based on the closed-loop control logic of "signal acquisition logic operation instruction output state feedback", with the core process as follows:

Signal acquisition stage: Real time data from current sensors and temperature detectors is received through analog input ports, filtered and isolated, converted into digital signals, and transmitted to the core processing unit.

Calculation processing stage: The embedded processor combines preset control logic (such as motor start stop curve, load protection threshold) to perform calculation and analysis on the collected signals, generating control instructions such as current regulation and equipment start stop.

Instruction output stage: Convert control instructions into analog or digital signals, drive motor drivers, contactors, and other actuators through output ports to achieve precise control of load current and operating status.

Feedback correction stage: The operating parameters of the actuator are transmitted back to the module through a feedback loop. The processor compares the actual values with the target values and dynamically corrects the output instructions to ensure control accuracy and stable operation of the equipment.

Precautions

1. Installation specifications

Adopting DIN rail vertical installation, with a reserved heat dissipation space of at least 20mm on both sides of the module, away from strong electromagnetic interference equipment such as frequency converters (spacing ≥ 30cm).

When wiring, distinguish between power lines and signal lines. The power lines use copper core cables (cross-sectional area ≥ 1.5mm ²), and the signal lines use shielded twisted pair cables. The shielding layer is grounded at one end to avoid signal interference.

2. Operation and maintenance

Before the first startup, the current detection circuit needs to be calibrated using Automation Builder software to ensure that the zero drift error is ≤ 0.1% FS

Check the tightness of the wiring terminals and module temperature every month (normal operation ≤ 60 ° C), perform a full function self check every quarter, and clean the dust in the heat dissipation holes to ensure heat dissipation efficiency.

3. Safety protection

Before installation and maintenance, it is necessary to cut off the power supply of the module and related equipment, and wait for the capacitor to discharge (at least 3 minutes) before operation.

The power circuit needs to be equipped with a 10A fast fuse and surge protector, with a grounding resistance of ≤ 4 Ω; When used in humid environments, an additional moisture-proof junction box is required.

Application scenarios

1. Manufacturing motor control

Production line motor speed regulation: Receive PLC speed commands, adjust the current of the conveyor belt motor (adjustable from 0.24A-63.0A), and cooperate with Modbus communication to achieve synchronous operation of multiple motors, suitable for assembly line conveying scenarios of automotive parts and electronic components.

Equipment load protection: Real time monitoring of stamping machine and machine tool motor current, triggering protection immediately when overload (exceeding 63A) or stalling occurs, cutting off motor power and uploading fault signals to reduce the risk of equipment damage.

2. Energy and power sector

Excitation control of small generators: By collecting the output current of the generator through analog input, adjusting the power supply current of the excitation coil, stabilizing the output voltage within the range of 230V-400V, and adapting to the control of small units in distributed power plants.

Fan and water pump speed regulation: Based on the pressure sensor signal of the pipeline network, dynamically adjust the current of the fan and water pump motors to achieve precise control of flow and pressure, reducing energy consumption by more than 20% compared to traditional fixed speed operation.

3. Process industry regulation

Speed control of mixing equipment: Receive temperature signals from the reaction kettle, adjust the current of the mixing motor to change the speed, ensure uniform mixing of materials, and adapt to intermittent production processes in chemical and food processing.

Heating load control: Control the power of the heating tube through current regulation, and achieve precise temperature control under 230V-400V voltage with temperature sensor feedback, with an error of ≤± 1 ° C, meeting the needs of plastic molding, pharmaceutical drying and other scenarios.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-