Foxboro FBM202 P0926EQ is a high-precision analog input module in the Foxboro brand I/A Series series under Schneider Electric. Its core function is to receive on-site thermocouple or millivolt signals and convert them into stable digital signals, achieving efficient data exchange with distributed control systems (DCS) and providing accurate signal acquisition support for industrial process control. This module adopts a compact and sturdy industrial grade design, with excellent anti-interference ability and environmental adaptability. It can operate stably for a long time in harsh industrial scenarios and is a key bridge component connecting on-site sensing equipment and control centers. It is equipped with 8 independent input channels and 1 isolated RTD reference junction compensation channel, supporting standard thermocouple signal access and thermocouple burnout detection, widely compatible with Foundation fieldbus devices, and adaptable to various industrial automation control needs.

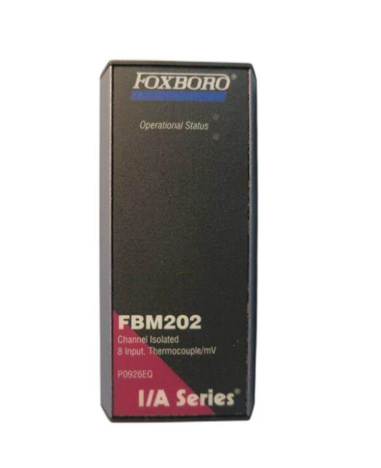

Foxboro FBM202 P0926EQ thermocouple/mV input module

Product Overview

Foxboro FBM202 P0926EQ is a high-precision analog input module in the Foxboro brand I/A Series series under Schneider Electric. Its core function is to receive on-site thermocouple or millivolt signals and convert them into stable digital signals, achieving efficient data exchange with distributed control systems (DCS) and providing accurate signal acquisition support for industrial process control. This module adopts a compact and sturdy industrial grade design, with excellent anti-interference ability and environmental adaptability. It can operate stably for a long time in harsh industrial scenarios and is a key bridge component connecting on-site sensing equipment and control centers. It is equipped with 8 independent input channels and 1 isolated RTD reference junction compensation channel, supporting standard thermocouple signal access and thermocouple burnout detection, widely compatible with Foundation fieldbus devices, and adaptable to various industrial automation control needs.

Specification parameters

-Core parameters: Model FBM202 P0926EQ, input type supports thermocouple and millivolt signals, equipped with 8 thermocouple input channels and 1 isolated RTD reference junction compensation channel (for terminal temperature sensing);

-Accuracy performance: The measurement accuracy reaches ± 0.03% of full scale (± 24 µ V), using Sigma Delta data conversion technology. Each channel can provide new analog input readings every 25ms, and supports configurable integration periods to eliminate process noise and power frequency interference;

-Environmental parameters: working temperature range of -40 ° C to 85 ° C, working humidity of 5% to 95% RH (non condensing), protection level of IP65, suitable for G3 level harsh environments;

-Power supply and communication: The power supply voltage supports 110V or 230V AC, and some specifications support 24V DC power supply. The communication interface is compatible with Ethernet bus and fieldbus protocols such as Modbus, Profibus DP, DeviceNet, etc;

-Physical specifications: The size is approximately 4.5 × 11.5 × 11.5cm (some specifications are 4.2 × 4.5 × 6 inches, approximately 10.7 × 11.4 × 15.2 cm), using a one-time formed aluminum alloy shell, weighing approximately 100g;

-Compliance standards: Compliant with ISA S71.04 standard, supports Foundation Fieldbus system, compatible with all Foundation Fieldbus devices and industrial grade components.

Performance characteristics

-High precision signal conversion: equipped with high-precision A/D converter and Sigma Delta data conversion technology, combined with configurable integration period design, effectively filters out interference signals, ensuring the accuracy and stability of signal acquisition and conversion;

-Full channel electrical isolation: Each input channel adopts a galvanic isolation design, which is completely isolated from other channels and grounding, avoiding signal crosstalk between channels, improving anti-interference ability and system safety;

-Complete protection function: equipped with thermocouple burnout detection (upper bias) function, which can monitor sensor fault status in real time; Industrial grade component selection and sturdy shell design, with excellent dust, water, and impact resistance performance;

-High reliability and stability: Supports redundant operation configuration, some specifications have hot swappable function, can be maintained and replaced without system shutdown, ensuring production continuity; Complete self diagnostic function, which can monitor CPU status, memory usage, power supply voltage, and communication link health status in real time;

-Flexible adaptability: Supports multiple standard thermocouple signal connections, compatible with multiple fieldbus protocols, and can seamlessly integrate with Foxboro I/A Series DCS systems and other mainstream PLC and DCS systems to meet the needs of different industrial scenarios;

-Strong usability: providing clear wiring identification and user-friendly configuration software, simplifying installation, debugging, and maintenance processes; The front panel is equipped with red and green LED status indicator lights, which can intuitively display the operation status of the module.

Working principle

The core working logic of Foxboro FBM202 P0926EQ module is to achieve the full process conversion and transmission of "on-site analog signal digital signal control system interaction". Firstly, on-site thermocouple sensors generate corresponding thermoelectric potentials (millivolt level signals) based on temperature changes, which are connected to one of the eight input channels of the module through wiring terminals; The built-in RTD reference junction compensation channel in the module real-time collects terminal temperature, performs cold end compensation on thermocouple signals, and eliminates the influence of environmental temperature on measurement accuracy; Subsequently, the signal is processed by a channel isolation circuit and sent to a high-precision A/D converter. The analog signal is converted to a digital signal through Sigma Delta data conversion technology, and the data is averaged within a configurable integration period to filter out process noise and power frequency interference; The processed digital signal is transmitted to the controller unit of the distributed control system (DCS) or PLC through Ethernet bus or fieldbus protocol. After the controller executes the control logic, the instructions are fed back to the on-site execution mechanism to achieve closed-loop control of the industrial process. At the same time, the module executes real-time self diagnostic programs to monitor channel status, power stability, and communication links. If faults such as thermocouple burnout are detected, an alarm signal is immediately sent to the upper system, and the fault status is indicated by LED indicator lights.

Precautions

-Installation specifications: Wiring must strictly follow the requirements of the product manual to ensure that the input signal type matches the channel configuration; Before wiring, the power supply should be disconnected to avoid module damage or personnel safety risks caused by live operation; The module should be installed in an environment with good ventilation, no severe vibration, and no strong electromagnetic interference, away from high temperature heat sources and corrosive gases;

-Power configuration: Select the appropriate power supply voltage according to the module specifications to avoid module failures caused by high or low voltage; The power supply circuit should be equipped with appropriate protective devices (such as fuses) to prevent overload or short circuit from affecting the operation of the module;

-Cold end compensation: Ensure that the terminals of the RTD reference junction compensation channel are clean and free of oxidation, and the installation position should be close to the thermocouple wiring terminals to avoid temperature gradients affecting compensation accuracy; Regularly calibrate compensation channels to ensure measurement accuracy;

-Maintenance and Calibration: Regularly calibrate the accuracy of the module, and it is recommended to follow the conventional requirements of industrial control equipment for calibration cycles (such as once a year); If it is necessary to plug and unplug modules during maintenance, it is necessary to confirm that the module supports hot plugging function. For non hot plugging specifications, the machine should be shut down and powered off first to avoid damaging the module or losing system data;

-Fault handling: If there is a signal abnormality or alarm prompt, first check whether the sensor wiring is loose and whether the thermocouple is damaged. Then, check the self diagnostic fault information through the upper system, locate the fault point, and carry out targeted treatment; When replacing a module, it is necessary to ensure that the new module model and specifications are consistent with the original module to avoid compatibility issues;

-Redundant configuration: When using redundant operation configuration, it is necessary to ensure that the parameter configuration of the main and backup modules is completely consistent, regularly test the redundant switching function, verify the switching reliability, and avoid system shutdown caused by the failure of the main and backup modules.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-