GE DS200RTBAG3AEB Power Excitation Board

GE DS200RTBAG3AEB Power Excitation Board

Product Overview

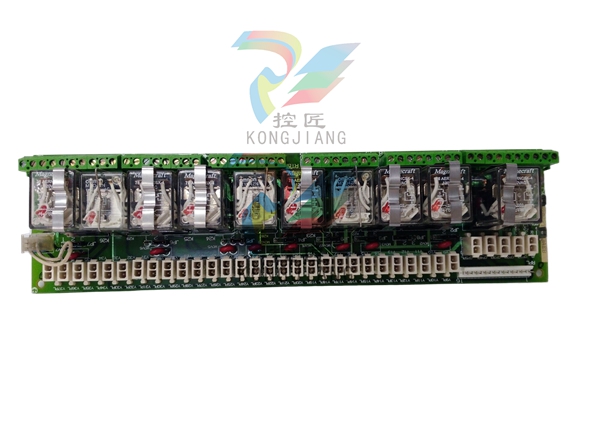

The GE DS200RTBAG3AEB power excitation board is an optional board manufactured by GE (General Electric) for installation in drive cabinets. It is designed for industrial automation and control systems, providing reliable power excitation to drive and control a variety of industrial equipment.

Main Functions

Power excitation:

The DS200RTBAG3AEB board has a power excitation function, which can provide a stable power supply for the connected motor or equipment to ensure the normal operation of the equipment.

Relay Control:

The board contains 10 relays that can be driven directly from the mapping relay or remotely by the user. The relays can be used to control the on/off state of various external devices.

Wiring Points:

The DS200RTBAG3AEB board provides 52 wiring points that can be used by the user to connect wires that control relay behaviour and drive through signals.

Technical features

Modular design:

The DS200RTBAG3AEB adopts a modular design, which is easy to install and replace and improves the flexibility and expandability of the system.

High Reliability:

The board has high reliability and is suitable for complex industrial environments, which can ensure the stable operation of the system.

Easy diagnosis:

Users can access diagnostics through the control panel on the drive to verify that relay settings are correct or to detect problems with the drive or DS200RTBAG3AEB board. The diagnostic program provides inclusive reports that users can download to a laptop for analysis.

Application Scenarios

GE DS200RTBAG3AEB power excitation board is widely used in industrial automation control systems, such as automated production lines, equipment monitoring and control systems. It can be used to control a variety of industrial equipment, such as motors, sensors, actuators, etc., to achieve precise motion control and process control.

Precautions

Safe Operation:

Before operating the DS200RTBAG3AEB board, make sure you have disconnected all power supplies and wait 5 seconds for the current to leave the assembly. Do not touch anything until you are sure the current has disappeared.

Proper Installation:

Follow the instructions in the product manual for proper installation to ensure that the DS200RTBAG3AEB board is properly and reliably connected to the drive.

Regular Maintenance:

Periodically inspect and maintain the DS200RTBAG3AEB board to ensure proper operation and stable performance.

Protection and control

• Thermal model biased with RTD and negative sequence current feedback

• Stator winding & bearing overtemperature • Motor multiple starts

• 8 standard overload curves

• User defined overload FlexCurve™

• Undercurrent for load loss

• Locked rotor

• Rapid trip/mechanical jam

• Unbalance/single phasing

• Short circuit

• Ground fault

• Phase reversal (meter option)

• Variable lock-out time

• Latched main trip relay, alarm relay

• 2 auxiliary relays

• Emergency restart capability

• Pre-trip alarm warnings

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-