YASKAWA JAMSC-B1063 is a high-performance positioning control module launched by Yaskawa brand, designed specifically for Yaskawa servo amplifiers. Its core positioning is high-precision servo motor positioning control unit in industrial automation scenarios. This module integrates integrated functions such as pulse train control, absolute/incremental positioning, and encoder signal acquisition, enabling precise linkage control between the upper controller and servo motor. Through industrial grade high reliability components and anti-interference structure design, it has high-frequency pulse output, precise positioning control, and excellent environmental adaptability. Its standardized installation interface and wide compatibility can be seamlessly integrated into various mainstream industrial automation control systems, providing core control support for scenarios such as CNC machining and precision assembly that require high positioning accuracy. It is a key adaptation module for high-precision servo control scenarios.

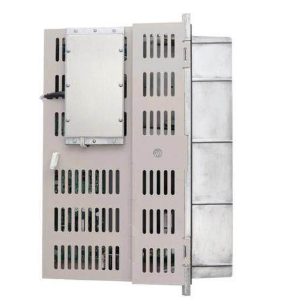

YASKAWA JAMSC-B1063 Industrial Control Module

Product Overview

YASKAWA JAMSC-B1063 is a high-performance positioning control module launched by Yaskawa brand, designed specifically for Yaskawa servo amplifiers. Its core positioning is high-precision servo motor positioning control unit in industrial automation scenarios. This module integrates integrated functions such as pulse train control, absolute/incremental positioning, and encoder signal acquisition, enabling precise linkage control between the upper controller and servo motor. Through industrial grade high reliability components and anti-interference structure design, it has high-frequency pulse output, precise positioning control, and excellent environmental adaptability. Its standardized installation interface and wide compatibility can be seamlessly integrated into various mainstream industrial automation control systems, providing core control support for scenarios such as CNC machining and precision assembly that require high positioning accuracy. It is a key adaptation module for high-precision servo control scenarios.

Specification parameters

Based on the technical standards of Yaskawa Industrial Automation series products and the general design specifications for positioning control modules, the core specification parameters of YASKAWA JAMSC-B1063 are as follows:

-Job Description: High precision positioning control card, integrating pulse train control, positioning mode switching, and encoder signal acquisition functions

-Adaptation device type: Yaskawa servo amplifier and matching servo motor, supporting high-precision motion control equipment

-Input voltage: 24VDC, meets the power supply requirements of industrial control standards

-Output voltage: 24VDC, matched with input voltage to ensure stable output of control signals

-Input current: 1.2A, output current: 1.2A, meets the requirements of conventional servo control signal transmission

-Maximum pulse output frequency: 500kHz, ensuring fast response of high-precision positioning control

-Number of control axes: 1 axis, focusing on single axis high-precision positioning control

-Control mode: Pulse train control, supporting absolute/incremental positioning modes

-Encoder input: A/B phase, 90 ° phase shift, 5VDC power supply, ensuring accurate acquisition of position signals

-Working environment: temperature 0 ℃~55 ℃, relative humidity 5%~95% RH (no condensation); Storage temperature -20 ℃~75 ℃

-Insulation level: Insulation resistance between terminals and between modules and enclosures>1000M Ω (50V DC), ensuring electrical safety

-Mechanical strength: possessing excellent resistance to vibration and impact (in compliance with industrial site mechanical environmental standards); Support standardized rail installation, with an installation interface plug life of ≥ 100 times

-Electromagnetic compatibility: Complies with the IEC 61000-4 series of industrial electromagnetic compatibility standards and has strong resistance to electromagnetic interference

-Product certification: Complies with the general certification standards for industrial automation products and relevant IEC specifications, ensuring safety and reliability of use

-Processing customization: supports processing customization and can adapt to the control requirements of specific scenarios

Performance characteristics

-High precision positioning control: supports both absolute and incremental positioning methods, with a maximum pulse output frequency of 500kHz, which can achieve high-precision position control of servo motors and meet the requirements of precision machining, precision assembly and other scenarios.

-Excellent signal response performance: Using pulse train control and A/B phase encoder signal acquisition (90 ° phase shift), it can quickly capture motor position signals, reduce control delays, and improve the accuracy and stability of positioning control.

-Strong environmental adaptability and reliability: Adopting industrial grade high specification components and reinforced structural design, it can work stably for a long time in a wide temperature range of 0 ℃~55 ℃ and a high humidity environment of 5%~95%. It has excellent anti vibration and anti impact capabilities and is suitable for complex industrial site environments.

-Exclusive adaptation and convenient integration: designed specifically for Yaskawa servo amplifiers, with excellent compatibility; Standardized installation interface and wiring design, high integration efficiency, and quick integration into existing control systems without the need for additional complex configurations.

-Comprehensive electrical safety guarantee: insulation resistance>1000M Ω (50V DC), with excellent insulation performance; Compliant with industrial electromagnetic compatibility standards, it can effectively block the impact of electromagnetic interference on control signal transmission in industrial sites, ensuring control stability.

-Flexible customization and adaptation capabilities: Supports processing customization, can adjust parameter configuration according to the control requirements of specific industrial scenarios, adapt to different types of precision control equipment, and enhance scene adaptation flexibility.

Working principle

The YASKAWA JAMSC-B1063 core is based on the working logic of "instruction reception pulse output position feedback precise control". As a high-precision positioning control unit in industrial automation systems, its core function is to achieve precise conversion and execution of positioning instructions from the upper controller, drive servo motors to complete specified position movements, and achieve position closed-loop control through encoder signal acquisition to ensure positioning accuracy.

The specific workflow is as follows: Firstly, the positioning control instructions (such as target position and motion speed instructions) issued by the upper controller are connected to the signal input terminal of YASKAWA JAMSC-B1063; The internal control unit of the module parses the received instructions, generates corresponding control pulse signals according to the pulse train control method, and transmits them to the matching Yaskawa servo amplifier through the output terminal; The servo amplifier drives the servo motor to operate based on the pulse signal, and the encoder matched with the servo motor feeds back the real-time position signal (A/B phase, 90 ° phase shift) to the encoder input of the module; The module collects and analyzes the feedback position signal, compares it with the target instruction of the upper controller, dynamically adjusts the frequency and quantity of the output pulse signal, and achieves position closed-loop control; Throughout the entire working process, the high anti-interference design of the module ensures stable transmission of control signals and feedback signals in the strong electromagnetic environment of the industrial site, avoiding signal distortion and positioning deviation; In addition, the overcurrent and overvoltage protection circuits of the module continuously monitor the power supply status to ensure that all parameters are within the normal working range, ensuring the safe operation of the module and associated equipment.

Application scenarios

The YASKAWA JAMSC-B1063 industrial control module, with its 500kHz high-frequency pulse output, absolute/incremental dual positioning mode, and precise encoder signal acquisition function, is widely used in industrial automation scenarios that require high-precision servo positioning control, especially suitable for core equipment with high requirements for positioning accuracy and control stability. It mainly includes:

-CNC machining equipment: integrated into the control system of CNC lathes, milling machines, machining centers and other equipment, providing high-precision positioning control for servo motors, ensuring precise positioning of tool movement during the machining process, and improving the machining accuracy of parts.

-Precision assembly production line: applied to precision assembly production lines for electronic components, automotive parts, etc., it drives servo motors to achieve precise material grasping, handling, and assembly, ensuring consistency and accuracy in the assembly process.

-Automated detection equipment: Suitable for precision measurement, visual inspection and other automated detection equipment, controlling servo motors to drive detection mechanisms to complete precise positioning and scanning, ensuring accurate alignment of detection points and improving the accuracy of detection data.

-Robot control system: applied to joint control units of small industrial robots and collaborative robots, achieving high-precision positioning and motion control of robot joint motors, ensuring the accuracy and smoothness of robot movements.

-Special precision equipment: Suitable for semiconductor manufacturing, medical equipment and other special precision equipment, providing high-precision positioning control for their core moving parts, meeting the strict requirements of the special industry for equipment control accuracy.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-