NU8976A99 is an industrial grade logic level input module (some suppliers label it as a digital I/O hybrid module) launched by ABB. Its core function is to receive logic level signals from external devices (such as switch status, sensor output, etc.), convert them into digital signals recognizable by the control system, and achieve real-time status monitoring and data acquisition in industrial scenarios. Its modular design makes it a key component of ABB automation systems, widely adaptable to various industrial control architectures.

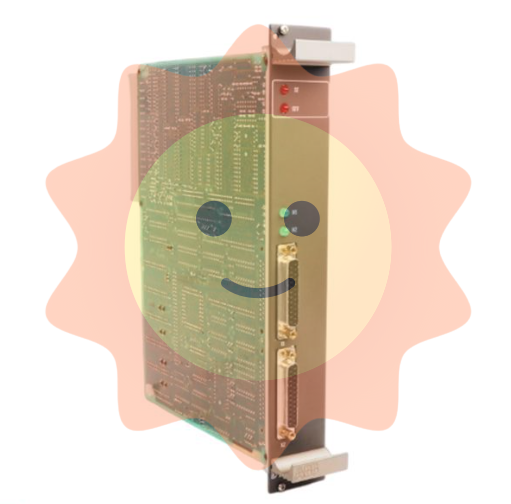

ABB NU8976A99 Digital Input Module

Product core positioning

NU8976A99 is an industrial grade logic level input module (some suppliers label it as a digital I/O hybrid module) launched by ABB. Its core function is to receive logic level signals from external devices (such as switch status, sensor output, etc.), convert them into digital signals recognizable by the control system, and achieve real-time status monitoring and data acquisition in industrial scenarios. Its modular design makes it a key component of ABB automation systems, widely adaptable to various industrial control architectures.

Key technical parameters

1. Signal and interface characteristics

Input type: logic level input, compatible with various standards such as TTL and CMOS, and can adapt to mainstream industrial sensor signals; Some information shows that it supports mixed processing of digital/analog signals, and the specific channel configuration should be based on the actual model.

Communication capability: Supports industrial protocols such as Profibus, Modbus, and Ethernet, equipped with interfaces such as RS-485 and Ethernet, and can seamlessly integrate with existing control systems.

Response performance: With fast signal response capability, the sampling rate can reach up to 50GSa/s (single channel), meeting real-time control requirements.

2. Environmental and physical parameters

Working temperature range

-40 ℃ to+85 ℃ or -20 ℃ to+60 ℃

Adapt to extreme industrial environments

Protection level

IP65

Dustproof and waterproof, suitable for installation outside control cabinets

Physical dimensions

180 × 82 × 480mm (mainstream specifications)

Compact design, compatible with standard control cabinets

Weight

0.66kg or approximately 200g

Due to differences in configuration, there may be variations

Power requirements

24V DC or 100-240V AC

Compliant with industrial power standards

3. Electrical safety characteristics

Output voltage: 24V DC, maximum output current 2A, with overload protection function;

Anti interference capability: Through electromagnetic compatibility testing, it can resist electromagnetic interference (EMI) in industrial environments and ensure signal stability.

Core performance advantages

High reliability: After rigorous environmental adaptability testing (high and low temperature, vibration, electromagnetic compatibility, etc.), it can operate stably for a long time in harsh scenarios such as manufacturing and energy.

Flexible Expansion: The modular architecture supports stacking multiple modules, allowing for the expansion of input channels and functionality according to requirements, reducing system upgrade costs.

Usability design: Adopting plug-in or screw fixed connections, equipped with an intuitive configuration interface, supporting multiple programming methods such as ladder diagrams and C language, simplifying installation and debugging processes.

Multiple protection: Built in fault diagnosis functions such as overload, short circuit, and overheating, which can provide real-time feedback on module status and enhance system safety.

Application scenarios and industry adaptation

1. Core application areas

Manufacturing industry: production line equipment status monitoring, process node control (such as automotive manufacturing, electronic assembly);

Energy industry: collection of operating parameters for wind and solar power equipment, monitoring of power system distribution status;

Transportation and infrastructure: railway signal collection, building security system status monitoring (such as access control, fire switch);

Environmental Protection and Water Affairs: Signal reception of liquid level and flow sensors in sewage treatment plants, and data transmission of pollution monitoring equipment.

2. Typical adaptation system

ABB AC500S series PLC system (as an extended I/O module);

The signal front-end acquisition unit of industrial DCS system (distributed control system).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-