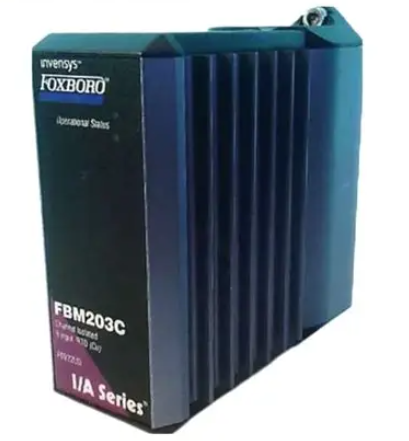

FOXBORO P0903NQ is a core control module launched by Foxboro Corporation in the field of industrial automation, belonging to its classic I/A series product lineup. This module integrates power supply and data communication functions, and adopts a modular structure design. It is mainly used to provide stable and reliable power support for industrial control equipment, and to achieve efficient data exchange and instruction transmission between devices.

With its compact size, excellent environmental adaptability, and mature industrial grade design, the P0903NQ module can be seamlessly integrated into various PLC control systems, serving as a key spare part to ensure the continuity of industrial production processes and widely serving automation control scenarios in multiple industries such as manufacturing, chemical, and energy.

FOXBORO P0903NQ control module

Product Overview

FOXBORO P0903NQ is a core control module launched by Foxboro Corporation in the field of industrial automation, belonging to its classic I/A series product lineup. This module integrates power supply and data communication functions, and adopts a modular structure design. It is mainly used to provide stable and reliable power support for industrial control equipment, and to achieve efficient data exchange and instruction transmission between devices.

With its compact size, excellent environmental adaptability, and mature industrial grade design, the P0903NQ module can be seamlessly integrated into various PLC control systems, serving as a key spare part to ensure the continuity of industrial production processes and widely serving automation control scenarios in multiple industries such as manufacturing, chemical, and energy.

Specification parameters

Basic Information

Brand: Foxboro; Model: P0903NQ; Series: I/A Series

Customized processing: No

Structure and Installation

Structural form: modular; Installation method: Control room installation

Easy to integrate and maintain

Electrical parameters

Working voltage: 24V DC; Output frequency: 30Hz; processing speed: 15Hz

Voltage stability, compatible with industrial standard power supply

storage capacity

Program capacity: 6MB; Data capacity: 3MB

Meet the storage requirements of conventional control programs

Physics and Authentication

Weight: approximately 1.2KG; Certification: UL certification; Origin: Europe and America

Compliant with international industrial safety standards

core component

LD instruction processor: hard PLC

Ensure the stability and real-time performance of instruction execution

Performance characteristics

-High reliability power supply: The module is equipped with a dual protection mechanism for overvoltage and overcurrent, which can effectively avoid damage to downstream equipment caused by voltage fluctuations or load abnormalities. At the same time, the output ripple and noise are extremely low, providing clean and stable power support for precision control equipment.

-Excellent environmental adaptability: Adopting industrial grade protection design, it can withstand harsh industrial environments such as high temperature, high dust, electromagnetic interference, etc. It can still maintain stable operation in complex scenarios such as steel smelting and electronic manufacturing, reducing the risk of failure in extreme environments.

-Efficient data processing capability: Equipped with a hard PLC instruction processor, coupled with 6MB program capacity and 3MB data capacity, it can quickly execute control instructions and store critical operational data, meeting the real-time and data integrity requirements of industrial automation systems.

-Convenient integration and maintenance: The modular structure design makes it easy to embed into existing PLC control systems, and standardized interfaces reduce the difficulty of compatibility with other devices; The lightweight (1.2KG) feature facilitates installation and disassembly, reducing labor costs for later maintenance.

Working principle

The FOXBORO P0903NQ control module is based on the core working logic of "power supply+instruction processing+data communication", forming a closed-loop control support system. The specific process is as follows:

1. Power conversion and stable output: After the module is connected to a 24V DC industrial power supply, it adjusts the voltage through an internal voltage regulator circuit, filters out interference signals in the power grid, and delivers clean power to connected control devices (such as sensors, actuators, PLC hosts, etc.). At the same time, the overvoltage/overcurrent protection circuit monitors the output status in real time, and immediately triggers the protection mechanism to cut off or adjust the output in case of abnormalities.

2. Instruction reception and high-speed processing: As the core spare part of the PLC system, the module receives LD instructions issued by the upper control system through the communication interface, and the built-in hard PLC processor parses and calculates them. Combined with the stored program logic (stored in 6MB program capacity), it quickly generates execution instructions and accurately transmits them to downstream execution units to ensure the timeliness of control actions.

3. Data feedback and interaction: The operating status data of downstream devices (such as temperature, pressure, operating parameters, etc.) is transmitted back through the input interface of the module, processed by the processor and stored in a 3MB data capacity. At the same time, it is synchronously uploaded to the upper system, providing real-time monitoring basis for operators and achieving a complete control loop of "instruction issuance action execution status feedback".

4. System collaboration and communication guarantee: The module serves as a communication hub, supporting seamless integration with industrial bus systems, integrating the data streams of dispersed devices and transmitting them in an orderly manner, ensuring collaborative operations between different devices and improving the linkage efficiency of the entire automation system.

Precautions

This module is an industrial grade control component, and its operation and maintenance must strictly follow safety regulations to avoid equipment damage or safety accidents caused by improper operation.

-Before installation, it is necessary to confirm that the module model matches the system requirements, carefully read the technical documentation provided by the manufacturer, clarify the interface definition and wiring specifications, and avoid misconnections that may cause short circuits and burns.

-It is necessary to use a 24V DC power supply that meets the specifications. It is strictly prohibited to connect power supplies beyond the rated voltage range. At the same time, ensure that the power supply line has reliable grounding measures to reduce the impact of electromagnetic interference.

-The installation environment should meet the requirements of good ventilation, no corrosive gases, and being away from strong magnetic fields. It is recommended to avoid direct exposure to water, oil, or dust dense areas. The working temperature should be controlled between -25 ° C and+60 ° C.

-During module operation, it is prohibited to randomly plug and unplug wiring or disassemble the casing. Before maintenance, the power supply must be cut off first, and the operation can only be carried out after the capacitor discharge is completed; Regularly check the contact status of the connector and clean the dust and oxide layer at the interface.

-Operators need to receive professional training, be familiar with the fault diagnosis methods of modules, and avoid modifying key parameters due to misoperation, which may affect the normal operation of the system.

Application scenarios

Based on its stable performance and wide compatibility, the FOXBORO P0903NQ control module has mature applications in multiple industrial fields, with core scenarios including:

1. Industrial automation production line: In automobile manufacturing, electronic component assembly and other production lines, modules provide power and communication support for CNC machine tools, robots, automated testing instruments and other equipment, realizing real-time data exchange between devices, ensuring timely feedback of component assembly accuracy and product quality testing data, and improving production efficiency.

2. Chemical Engineering and Process Control: In continuous production scenarios such as chemical engineering and petroleum refining, modules can withstand harsh environments with high temperatures and corrosive gases, providing stable power supply for equipment such as reaction vessels, flow meters, and valve actuators, and transmitting key process parameters such as pressure, temperature, and liquid level in real time to ensure the safety and controllability of the production process.

3. Ship automation control: In the face of complex environments such as vibration and humidity changes during ship navigation, modules serve as the core spare parts of ship automation systems, providing reliable power and data processing support for navigation equipment, power control systems, and cabin monitoring equipment, ensuring safe navigation and stable equipment operation.

4. Energy and Power System: In scenarios such as thermal power generation and new energy power stations, modules are connected to the power control system to provide power for monitoring units of key equipment such as boilers and turbines. Real time transmission of data on power generation and energy consumption helps optimize power generation efficiency and ensure stable power supply.

5. Intelligent warehousing and logistics: In e-commerce warehousing and industrial warehouses, modules provide communication hub functions for AGV (Automated Guided Vehicle), stacker cranes, conveyors and other equipment, enabling collaborative operations between devices, real-time transmission of warehousing data to management systems, and improving the efficiency of goods sorting and storage.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-