FOXBORO P0926PA is a high-performance industrial control module launched by FOXBORO Corporation, belonging to the I/A series (some scenarios are classified as FPS400 series), with the core positioning of input/output (I/O) terminal components and control pulse modules. Its core function is to build a communication bridge between on-site instruments, sensors, actuators, and the central control system, achieving bidirectional signal conversion, data acquisition, real-time monitoring, and precise control. This module, with its modular design and wide environmental adaptability, can be seamlessly integrated into various industrial automation systems, providing stable and reliable control solutions for complex industrial scenarios, and widely adapting to the automation needs of multiple fields such as process industry, energy industry, and manufacturing.

FOXBORO P0926PA Industrial Control Module

Product Overview

FOXBORO P0926PA is a high-performance industrial control module launched by FOXBORO Corporation, belonging to the I/A series (some scenarios are classified as FPS400 series), with the core positioning of input/output (I/O) terminal components and control pulse modules. Its core function is to build a communication bridge between on-site instruments, sensors, actuators, and the central control system, achieving bidirectional signal conversion, data acquisition, real-time monitoring, and precise control. This module, with its modular design and wide environmental adaptability, can be seamlessly integrated into various industrial automation systems, providing stable and reliable control solutions for complex industrial scenarios, and widely adapting to the automation needs of multiple fields such as process industry, energy industry, and manufacturing.

Specification parameters

The specifications and parameters of this module have been optimized for industrial scenarios, taking into account compatibility and stability. The key parameters are as follows:

-Signal specifications: Input supports analog signals (4-20mA current signal, 1-5V/± 10V voltage signal), digital pulse signals, and some models are compatible with thermocouple and RTD signals; Output supports analog signals (4-20mA current signal, 0-10V voltage signal) and digital switch signals (on/off control).

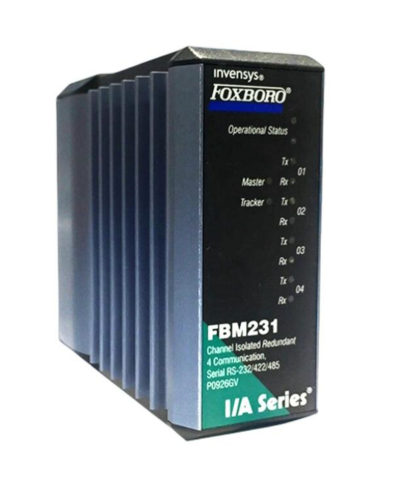

-Channel configuration: Equipped with 4 input/output channels, it can simultaneously connect multiple sensors and actuators to achieve parallel processing of multiple signals.

-Communication interface: Supports serial communication interfaces such as RS-232, RS-422, RS-485, etc., compatible with mainstream industrial communication protocols such as Modbus, Profibus, Ethernet, etc., and adaptable to different system integration requirements.

-Power parameters: The power demand is 24V DC, the output current can reach 4A, and the rated power is 96W.

-Environmental adaptability: Operating temperature range of -40 ° C to 85 ° C (some models range from -20 ° C to 60 ° C), protection level IP65, able to withstand high temperature, high humidity, vibration and other interference in harsh industrial environments.

-Physical dimensions: 70mm x 150mm x 135mm, weighing approximately 0.5kg, convenient for installation and system integration.

Performance characteristics

-Modular design: Adopting a standardized plug-in structure, supporting on-demand expansion and flexible configuration, it can quickly adapt to control systems of different scales, reducing system upgrade and maintenance costs.

-High precision data processing: Equipped with high-performance processors and integrated with advanced signal filtering and calibration algorithms, it can accurately collect and process sensor signals, ensuring the accuracy and reliability of data transmission and supporting high-precision measurement scene requirements.

-Multi functional integration: It combines multi-channel signal input/output, real-time monitoring, fault diagnosis, alarm triggering and other functions, enabling full process control of industrial field equipment without the need for additional auxiliary modules.

-Strong compatibility and interconnectivity: Supports multiple communication protocols and interface types, seamlessly integrates with FOXBORO I/A series control systems and other mainstream industrial automation systems, and adapts to sensors and actuators from different brands.

-High reliability and durability: Compliant with industrial safety standards, it has a sturdy shell structure and good anti-interference ability, and can operate stably in harsh industrial environments such as corrosive gases and strong vibrations for a long time.

-Strong usability: The installation process is simple, supports custom programming configuration, and can set control logic and alarm thresholds according to specific application needs. The debugging and operation difficulty is low, and ordinary operation and maintenance personnel can handle it.

Working principle

The core working logic of FOXBORO P0926PA module is to achieve bidirectional conversion and data exchange between "on-site signal control system signal". The specific process is as follows:

1. Signal acquisition stage: The module connects on-site sensors (such as pressure, temperature, liquid level sensors, etc.) and instruments through input channels, receives analog signals (4-20mA, 1-5V, etc.) or digital pulse signals, and filters, amplifies, and calibrates the original signals to eliminate the impact of environmental interference on signal accuracy.

2. Data transmission stage: The processed signal is transmitted to central control systems such as FOXBORO I/A series controllers through built-in communication interfaces (such as RS-485, Ethernet) and compatible protocols (such as Modbus, Profibus), providing real-time data support for system decision-making.

3. Control instruction execution stage: Receive control instructions issued by the central control system, convert them into analog output signals (4-20mA, 0-10V) or digital switch signals that can be recognized by the actuators, and drive actuators such as motors and valves through output channels to achieve precise control of industrial processes.

4. Fault monitoring and alarm stage: The module monitors its own operating status and input/output signal status in real time, identifies signal abnormalities, line faults, and other issues through built-in fault diagnosis algorithms, triggers alarm notifications, and records fault information to ensure the safe operation of the system.

Precautions

-Installation environment requirements: It should be installed in a ventilated and dry environment, avoiding direct exposure to high temperature, high humidity, corrosive gases, strong vibration or direct sunlight, and ensuring that the environmental parameters meet the requirements of the module's working temperature and protection level.

-Electrical connection specifications: Strictly follow the manufacturer's wiring guidelines, correctly connect the power supply and input/output signal lines, ensure correct polarity, secure wiring, and avoid module failures caused by short circuits, poor contacts, or signal interference.

-Software compatibility confirmation: When configuring and programming, it is necessary to ensure that the software used is compatible with the module model to avoid control logic errors or system conflicts caused by software version mismatch.

-System integration verification: When integrating into existing control systems, it is necessary to test the compatibility of modules with controllers, sensors, and actuators in advance to ensure smooth data transmission and instruction execution, and to avoid overall system failures.

-Regular maintenance and inspection: Regularly clean the module housing and interfaces, check the integrity of connectors and circuits; Update firmware in a timely manner according to the manufacturer's recommendations to ensure stable module performance; Before restarting after a long-term shutdown, a comprehensive signal and functional test is required.

-Safety operation regulations: When handling high-voltage power sources or high current lines, it is necessary to strictly comply with industrial safety regulations and wear protective equipment; When a module fails, the power should be cut off before maintenance to avoid the risk of electric shock or equipment damage.

-Technical support assistance: When encountering technical problems that cannot be solved, it is necessary to promptly contact the technical support team of FOXBORO (or its authorized service provider) to avoid disassembling the module and causing secondary damage.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-