FOXBORO P0973BU is a fiber optic jumper product designed by Foxboro Corporation for industrial high-frequency signal transmission, belonging to its industrial communication transmission product line. This product uses high-purity quartz fiber core as the signal transmission carrier, paired with precision ceramic plug-in connectors. Its core function is to achieve low loss and high fidelity transmission of high-frequency optical signals in industrial automation systems. As a key connection medium between devices, it can efficiently couple the optical energy of the transmitting and receiving ends, minimizing attenuation and interference during signal transmission. It adopts an industrial grade protective sheath design, which can adapt to complex environments such as vibration, temperature and humidity fluctuations in industrial sites, and provide stable and reliable physical connection guarantees for high-frequency communication links in fields such as petrochemicals and power.

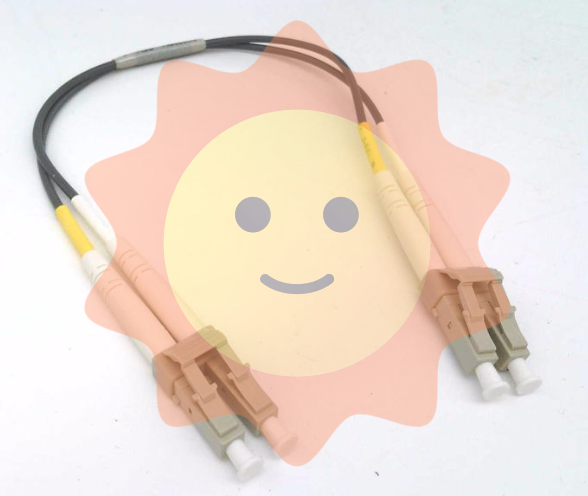

FOXBORO P0973BU high-frequency fiber optic jumper

Product Overview

FOXBORO P0973BU is a fiber optic jumper product designed by Foxboro Corporation for industrial high-frequency signal transmission, belonging to its industrial communication transmission product line. This product uses high-purity quartz fiber core as the signal transmission carrier, paired with precision ceramic plug-in connectors. Its core function is to achieve low loss and high fidelity transmission of high-frequency optical signals in industrial automation systems. As a key connection medium between devices, it can efficiently couple the optical energy of the transmitting and receiving ends, minimizing attenuation and interference during signal transmission. It adopts an industrial grade protective sheath design, which can adapt to complex environments such as vibration, temperature and humidity fluctuations in industrial sites, and provide stable and reliable physical connection guarantees for high-frequency communication links in fields such as petrochemicals and power.

Specification parameters

Basic Information

Product type: Single mode high-frequency fiber optic jumper; Country of Origin: United States; Sheath color: blue (identification feature)

Core parameters of optical fiber

Core material: high-purity quartz; Core diameter: 9 μ m; Cladding diameter: 125 μ m; Coating layer diameter: 250 μ m; Numerical aperture: 0.14

transmission performance

Working wavelength: 1310nm/1550nm dual window; Insertion loss: ≤ 0.3dB (typical value 0.15dB); Return loss: ≥ 50dB; transmission rate: supports high-frequency signals of 10Gbps and above; Transmission distance: ≤ 10km under 1310nm window, ≤ 40km under 1550nm window

Connector parameters

Connector type: SC/FC/LC optional (default SC-UPC); Insert material: zirconia ceramic; Plug and unplug lifespan: ≥ 1000 times; Connection method: plug-in, with dust cap protection

Physical and environmental parameters

Cable outer diameter: 2.0mm/3.0mm optional; Length specification: 1m/2m/3m/5m/10m customized; Working temperature: -40 ° C to 85 ° C; Storage temperature: -50 ° C to 90 ° C; Humidity: 0% -95% without condensation; Minimum bending radius: static 15mm, dynamic 30mm; tensile strength: ≥ 100N

Performance characteristics

-High frequency and low loss transmission: using 9 μ m single-mode quartz fiber core and high-precision grinding connector, optimized design for 1310nm/1550nm communication window, with extremely low insertion loss and low echo reflection, capable of stably carrying 10Gbps and above high-frequency signals, meeting the real-time transmission needs of industrial big data.

-Excellent anti-interference ability: Based on the principle of optical signal transmission, it completely avoids the influence of electromagnetic interference (EMI) and radio frequency interference (RFI), and can still maintain the stability and integrity of signal transmission in strong electromagnetic environments such as high-voltage substations and large motor groups, solving the bottleneck of traditional copper cable transmission.

-Industrial grade structural protection: using flame-retardant polyvinyl chloride (PVC) or low smoke halogen-free (LSZH) sheath, wear-resistant, tensile and has certain anti-corrosion ability; Ceramic plugs have high hardness and strong wear resistance, and can maintain good connection performance even after thousands of insertions and removals, adapting to mechanical vibrations and environmental erosion in industrial sites.

-Wide environmental adaptability: The working temperature covers an extreme range of -40 ° C to 85 ° C, and can operate stably in harsh environments such as outdoor cold regions and high-temperature workshops; Wide humidity adaptation range and excellent anti-aging performance extend the service life of the product in industrial scenarios.

-Easy and reliable installation: The standardized connector design enables quick insertion and removal, and the dust cap effectively prevents contamination of the plug end face; The cable has good flexibility, with a minimum static bending radius of only 15mm, making it easy to install and lay cables in densely packed industrial cabinets.

Working principle

FOXBORO P0973BU high-frequency fiber optic jumper is based on the principle of total reflection of light to achieve efficient transmission of high-frequency signals. The core process revolves around "optical signal coupling transmission reception", which is divided into three stages:

1. Optical signal coupling input: The transmitting end of industrial communication equipment (such as FOXBORO I/A series control modules, optical transceivers) converts high-frequency electrical signals into specific wavelength optical signals, and precisely couples the optical signals into the fiber core through the ceramic connector end face of the jumper. The high-precision grinding process of the connector ensures that the maximum amount of light energy enters the fiber core, reducing coupling losses.

2. Total reflection transmission of optical signals: The refractive index difference between the fiber core and the cladding (the refractive index of the fiber core is higher than that of the cladding) causes the optical signal entering the fiber core to undergo total reflection at the interface between the two, and the optical signal is confined inside the fiber core to continuously reflect and transmit forward, avoiding energy leakage. The coating layer and sheath isolate external light interference and physical damage, ensuring that the optical signal maintains high-frequency characteristics and stable intensity during transmission.

3. Optical signal coupling output: After the optical signal is transmitted to the other end of the jumper, it is efficiently coupled to the receiving device through a connector of the same specification. The receiving device then restores the optical signal to an electrical signal, completing the closed-loop transmission of high-frequency data. The entire process, due to the characteristics of optical signal transmission, effectively avoids the influence of electromagnetic interference on high-frequency signals and ensures transmission quality.

Precautions

-Connector protection: When not in use, a dust cap must be worn on the connector to prevent dust and oil contamination of the ceramic plug end face; Before use, gently wipe the end face of the plug with a degreased cotton soaked in anhydrous alcohol to avoid contamination that may cause increased insertion loss or damage to the plug.

-Cable operation specifications: Excessive bending or stretching of cables is strictly prohibited during wiring and storage, ensuring that the bending radius is not less than the specified value (static 15mm, dynamic 30mm) to avoid fiber core breakage; It is strictly prohibited to drag the connector part for cable movement to prevent the connector from loosening or being damaged.

-Installation environment requirements: Avoid installation and use in environments with high temperatures, open flames, and strong corrosive gases; When installed outdoors or in humid environments, it is necessary to use a waterproof junction box to prevent moisture from entering the connector and affecting its transmission performance.

-Safety operation warning: When the jumper is connected to the working optical equipment, it is strictly prohibited to look directly at the connector end face to avoid high-frequency laser damage to the human eye; When conducting link testing, it is necessary to confirm that the optical power is within a safe range and wear protective goggles during operation.

-Key points for troubleshooting: If there is an abnormal signal transmission, first check whether the connector is tightly inserted and whether the end face is clean; Visible laser pens can be used for on/off testing, or insertion loss can be measured using an optical power meter to determine if the jumper is functioning properly; Jumpers that are artificially damaged or exceed their insertion and removal lifespan should be replaced in a timely manner.

-Storage and transportation: When storing, the jumper wire should be coiled and placed in a dry and ventilated environment, avoiding direct sunlight and heavy objects from squeezing; During transportation, take measures to prevent falls and pressure to prevent damage to cables and connectors.

Application scenarios

As a key connecting component for industrial high-frequency communication, FOXBORO P0973BU is widely used in industrial scenarios with strict requirements for signal transmission rate and stability. Its core applications include:

1. Industrial automation control system: used for high-frequency data transmission between control modules and operation stations, IO units in FOXBORO I/A series DCS systems, as well as remote communication between PLC and SCADA systems, to ensure real-time interaction between production instructions and monitoring data.

2. Power industry: deployed in the comprehensive automation system of substations to achieve high-frequency signal transmission between relay protection devices, measurement and control devices, and backend monitoring systems; Used for data communication between combiner boxes and inverters in wind power plants and photovoltaic power stations, suitable for outdoor extreme environments.

3. Petroleum and chemical industry: In oil and gas extraction platforms and chemical production facilities, distributed control systems (DCS) are connected to on-site instruments and actuators to achieve stable transmission of high-frequency process data in high temperature, high humidity, and strong corrosive environments, supporting precise control of the production process.

4. In the field of intelligent manufacturing: Industrial Ethernet links used for smart factories, connecting industrial robots, visual inspection equipment, and control centers, carrying high-frequency image data and control signals of over 10Gbps, meeting the real-time requirements of flexible production.

In the field of transportation and energy, long-distance high-frequency communication between signal machines and control centers is achieved in the rail transit signal system; In large data centers and industrial computer rooms, high-speed optical links are used to connect servers and storage devices, improving data exchange efficiency.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-