The ABB PDP22-FBP fieldbus interface is a key communication component in ABB process automation control systems, specifically designed to enable efficient data exchange between distributed control systems (DCS) and on-site intelligent devices. As a "bridge" connecting the control layer and the device layer, this interface module can accurately transmit the operational data of various intelligent instruments, actuators, and other devices on the fieldbus network to the control system, while receiving control instructions issued by the system, achieving centralized monitoring and decentralized control of field devices. It is widely used in process industries such as chemical, petroleum, power, and metallurgy.

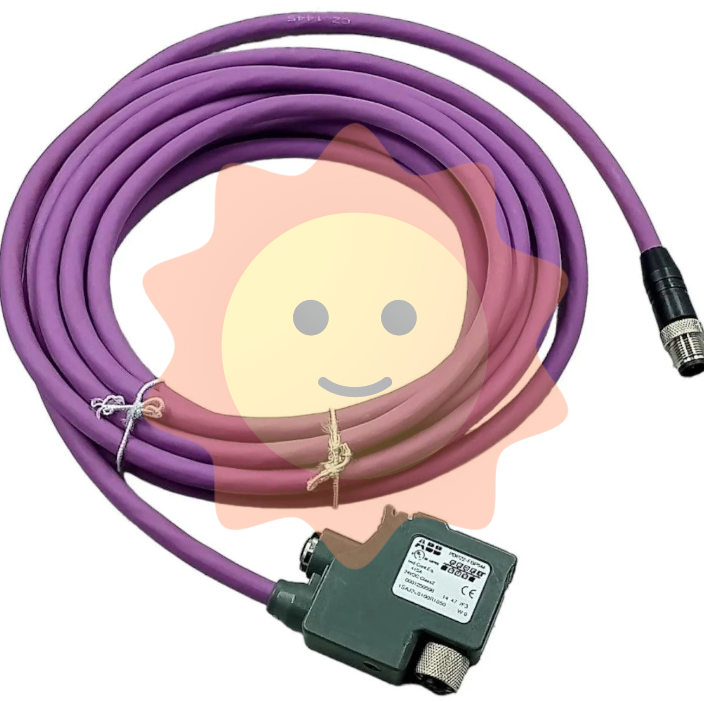

ABB PDP22-FBP fieldbus interface

Product Overview

The ABB PDP22-FBP fieldbus interface is a key communication component in ABB process automation control systems, specifically designed to enable efficient data exchange between distributed control systems (DCS) and on-site intelligent devices. As a "bridge" connecting the control layer and the device layer, this interface module can accurately transmit the operational data of various intelligent instruments, actuators, and other devices on the fieldbus network to the control system, while receiving control instructions issued by the system, achieving centralized monitoring and decentralized control of field devices. It is widely used in process industries such as chemical, petroleum, power, and metallurgy.

This interface module relies on ABB's mature industrial communication technology, with high reliability, strong anti-interference ability, and flexible adaptation characteristics. It can be seamlessly integrated into mainstream DCS systems such as ABB AC 800M and Freelance, providing solid communication support for the stable operation of industrial automation production processes.

Core functional features

1. Efficient data communication

Supports PROFIBUS-FMS (Fieldbus Message Specification) fieldbus protocol, adopts serial communication mode, and the data transmission rate can be flexibly configured between 9.6kbit/s and 12Mbit/s according to the on-site requirements, meeting the real-time communication needs of industrial sites of different scales. Capable of processing input/output data from multiple on-site devices simultaneously, achieving rapid collection of batch data and instruction issuance, ensuring real-time response of control instructions and accuracy of data transmission.

2. Flexible device adaptation

Compatible with various intelligent field devices that comply with the PROFIBUS-FMS protocol, including pressure transmitters, temperature sensors, flow meters, regulating valves, etc., without the need for additional dedicated drivers, reducing the difficulty of equipment integration. Supports multiple master/slave modes, which can be used as a master to manage and read/write data from on-site slave devices, as well as a slave to receive instructions from higher-level control systems, adapting to complex fieldbus network topologies.

3. High reliability and stability

Adopting industrial grade hardware design, it has a wide temperature working range (usually -20 ℃ to+60 ℃) and can adapt to harsh temperature environments in industrial sites. Built in comprehensive fault diagnosis and fault tolerance mechanism, including communication link detection, data verification, power overcurrent protection and other functions. When communication interruption, data error or power abnormality occurs, the alarm signal can be quickly triggered and fault information can be recorded, making it easy for operation and maintenance personnel to troubleshoot in a timely manner.

4. Convenient integration and configuration

Support parameter configuration through specialized configuration software such as ABB Control Builder M, with a graphical user interface that is intuitive and easy to understand. Operations personnel can quickly set and modify parameters such as communication rate, device address, and data mapping relationships. Equipped with online debugging function, it can monitor communication status and data transmission in real time, facilitating fault diagnosis and parameter optimization before the system is put into operation.

5. Strong anti-interference ability

By using differential signal transmission technology combined with optoelectronic isolation design, it effectively suppresses electromagnetic interference (EMI) and radio frequency interference (RFI) in industrial sites, ensuring the stability of data transmission in complex electrical environments. The interface circuit has surge protection function, which can withstand the impact of instantaneous overvoltage and overcurrent on the module on site and extend the service life of the equipment.

Key technical parameters

communication protocol

PROFIBUS-FMS

Compliant with IEC 61158 standard

transmission rate

9.6kbit/s - 12Mbit/s

Can be configured through configuration software

communication interface

RS-485 (differential signal)

Support multiple device connections, the maximum number of nodes depends on the protocol specifications

Power requirements

DC 24V ±10%

Typical power consumption ≤ 5W

Operating Temperature

-20℃ - +60℃

Industrial grade wide temperature design

Storage temperature

-40℃ - +85℃

Adapt to transportation and storage needs

Protection level

IP20 (module itself)

It needs to be installed inside the control cabinet for use

Installation method

DIN rail installation

Compatible with standard 35mm DIN rail

fault diagnosis

LED indicator light+software alarm

Visual display of power supply, communication status, and fault information

Applicable scenarios

The ABB PDP22-FBP fieldbus interface is widely used in various process industries and discrete manufacturing fields due to its stable communication performance and flexible adaptability. Typical application scenarios include:

1. Petrochemical industry: used in refining and chemical plants to connect intelligent instruments such as pressure, temperature, flow rate, etc. on site, to achieve real-time collection and control of operating parameters of equipment such as reaction vessels and distillation towers, ensuring the stability and safety of the production process.

2. Power industry: In thermal power, hydropower, nuclear power and other power plants, it is integrated into the control system of the generator set, connected to equipment such as steam drum water level gauges, steam flow meters, valve actuators, etc., to achieve precise control of the power generation process and improve power generation efficiency.

3. Metallurgical industry: applied to steel and non-ferrous metal smelting production lines, connecting various sensors and actuators of blast furnaces, converters and other equipment, transmitting key data such as temperature, liquid level, pressure, etc., supporting automation control of smelting processes.

4. Water treatment industry: In waterworks and sewage treatment plants, it is used to connect water quality monitoring instruments, pumps, valves and other equipment to achieve remote monitoring and automatic control of the water treatment process, ensuring that the effluent quality meets the standards.

5. Pharmaceutical industry: Intelligent instruments that comply with strict standards for pharmaceutical production, connect fermentation tanks, filters, and other equipment to achieve precise collection and traceability of drug production process parameters, meeting GMP certification requirements.

Key points for installation and maintenance

1. Installation specifications

-The module needs to be installed in a well ventilated, dust-free, and non corrosive gas control cabinet, avoiding direct sunlight and rainwater erosion, and ensuring that the working environment meets temperature and humidity requirements.

-Installed using standard 35mm DIN rails, the distance between the module and other equipment should be kept at least 5cm during installation to facilitate heat dissipation and maintenance operations.

-The communication line adopts shielded twisted pair cables, and the shielding layer needs to be grounded at one end to reduce interference; When laying the line, it should be kept away from the power cable to avoid parallel laying. If crossing, it should be done vertically to reduce electromagnetic coupling interference.

-The power wiring should strictly distinguish between positive and negative poles to avoid reverse connection; It is recommended to install a fuse (1A) at the power input end to prevent overcurrent damage to the module.

2. Daily maintenance

-Status monitoring: Regularly check the LED indicator lights on the module panel, and determine the operation status of the equipment through the status of the power light (PWR), communication light (COM), and fault light (ERR). If the fault light stays on, it is necessary to promptly query the cause of the fault through the configuration software.

-Cleaning and maintenance: Clean the module once a quarter, wipe the dust on the surface of the module with a dry soft cloth, avoid using wet cloths or corrosive cleaning agents, and prevent equipment short circuits or corrosion.

-Line inspection: Regularly check the connection of communication lines and power lines to ensure that the wiring is secure, free from looseness or oxidation; Check if the grounding of the shielding layer is good and promptly address any issues with poor grounding.

-Software maintenance: Regularly backup configuration parameters to avoid parameter loss due to module failures; If you need to upgrade the module firmware, you need to follow the upgrade process provided by ABB to prevent equipment damage caused by upgrade failure.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-