The ABB PFCL201CE 10KN 3BSX105983-100 weighing sensor is a high-precision and highly reliable industrial grade weighing and detection component under the ABB brand. The product model number "3BSX105983-100" represents the exclusive material code, and "10KN" represents its core range specification. It is widely used in various industrial weighing scenarios and can accurately collect object weight signals and convert them into transferable electrical signals, providing core data support for weight monitoring and quality control in the production process. This sensor combines ABB's advanced sensing technology with strict manufacturing standards, and has good environmental adaptability and long-term stability. It is suitable for weighing systems in multiple industries such as metallurgy, chemical engineering, logistics, and food processing.

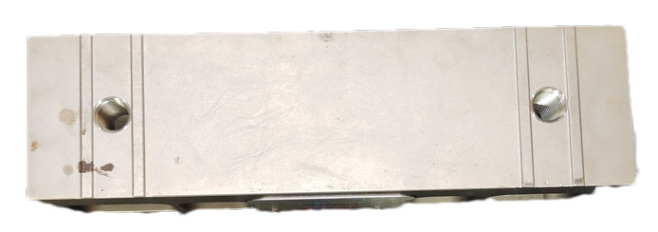

ABB PFCL201CE 10KN 3BSX105983-100 Weighing Sensor

Product Overview

The ABB PFCL201CE 10KN 3BSX105983-100 weighing sensor is a high-precision and highly reliable industrial grade weighing and detection component under the ABB brand. The product model number "3BSX105983-100" represents the exclusive material code, and "10KN" represents its core range specification. It is widely used in various industrial weighing scenarios and can accurately collect object weight signals and convert them into transferable electrical signals, providing core data support for weight monitoring and quality control in the production process. This sensor combines ABB's advanced sensing technology with strict manufacturing standards, and has good environmental adaptability and long-term stability. It is suitable for weighing systems in multiple industries such as metallurgy, chemical engineering, logistics, and food processing.

Core technical parameters

Product Model

PFCL201CE

Exclusive models for ABB weighing sensor series

Material Code

3BSX105983-100

Product unique identification code, used for procurement and traceability

Rated range

10KN

The maximum weight that can be stably measured corresponds to approximately 1000kg (calculated based on a gravity acceleration of 9.8m/s ²)

accuracy class

C3 level (typical)

Meets industrial weighing accuracy standards and is suitable for scenarios with medium precision requirements

sensitivity

2.0mV/V ± 0.02mV/V (typical)

The sensor output signal changes with excellent consistency for every 1V change in power supply voltage

power supply voltage

10-30VDC

Wide voltage adaptation to meet different power supply needs in industrial sites

Output signal range

0-4mV (corresponding to 0-10KN, when powered by 10VDC)

The signal output is linearly proportional to the weight, making it easier for subsequent equipment to collect data

Working temperature range

-20℃~+80℃

Adapt to high and low temperature industrial environments without the need for additional temperature control devices

Protection level

IP67

Dustproof and resistant to short-term immersion, suitable for humid and dusty industrial sites

structural form

Shear beam type

Strong anti eccentric load capability, easy installation, suitable for various weighing platforms

connection method

4-wire/6-wire system (optional)

The 6-wire system can compensate for the influence of wire resistance and improve the accuracy of long-distance transmission

Product advantages

-High precision and high stability: Adopting ABB's dedicated strain gauges and signal conditioning technology, the sensitivity drift is small, and the accuracy attenuation is low after long-term use, meeting the precise weighing requirements in continuous production processes.

-Excellent environmental adaptability: With an IP67 protection level and a wide temperature working range, it can resist dust, water vapor erosion, and temperature fluctuations in industrial sites, reducing the impact of harsh environments on measurements.

-Strong anti-interference ability: Built in electromagnetic interference suppression circuit can effectively resist electromagnetic radiation, voltage fluctuations and other interferences in industrial sites, ensuring stable and reliable output signals.

-Convenient installation and maintenance: The shear beam structure design has lower requirements for the installation surface, and standardized connection interfaces facilitate on-site wiring and later maintenance, reducing downtime.

-Complete brand guarantee: Relying on ABB's global service network, products have a complete quality traceability system and professional technical support, reducing equipment usage risks.

Applicable scenarios

1. Industrial weighing platform: used for ingredient weighing and finished product weight detection in production workshops, such as chemical raw material ingredient scales, food packaging weight re inspection scales, etc.

2. Logistics and Warehousing: Adapt to weighing scales and pallet scales in warehousing logistics to achieve fast and accurate collection of cargo weight, and improve warehousing management efficiency.

3. Metallurgy and Building Materials: Used for tank weighing and production line material measurement in industries such as steel and cement, ensuring the stability of production processes.

4. Automated production line: integrated into the automated production system to achieve real-time monitoring and closed-loop control of material weight during the production process, improving product quality consistency.

5. Special weighing scenarios: In some scenarios that require high reliability of sensors, such as sterile weighing environments in the pharmaceutical industry, stable performance is used to meet special needs.

Installation and usage precautions

-Before installation, it is necessary to check whether the appearance of the sensor is intact, confirm that the material code and model meet the usage requirements, and avoid misuse.

-The installation surface should be flat and sturdy to ensure even force distribution on the sensor and avoid measurement errors caused by tilting or loosening of the installation surface.

-When wiring, it is necessary to strictly follow the pin definitions in the product manual, distinguish between the positive and negative poles of the power supply and the signal output line, and avoid reversing the connection to burn out the sensor.

-Sensor cables should be kept away from sources of interference such as strong current cables and frequency converters. If long-distance transmission is required, it is recommended to use shielded cables and ground them properly.

-During use, avoid impact loads exceeding the rated range to prevent damage to the sensor strain gauges and extend their service life.

-Regularly calibrate sensors, and it is recommended to synchronize the calibration cycle with the maintenance cycle of production equipment to ensure that the measurement accuracy meets the requirements.

-When used in humid and corrosive environments, additional protective measures can be taken, such as installing protective covers, to prevent the sensor housing from being corroded.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-