The ABB PM820-2 PLC pulse counting module is a functional module designed specifically for industrial automation scenarios. It is an extension component of the AC 800M series PLC and its core function is to accurately collect and process pulse signals output by field devices such as encoders, flow meters, counters, etc., to achieve quantitative monitoring and control of physical quantities such as speed, flow rate, displacement, and output. As an important supporting component of the PM820-1 processor module, it can seamlessly integrate into the AC 800M system, making up for the shortcomings of the main processor in high-frequency pulse signal processing, and providing reliable data support for high-precision industrial control scenarios such as production line measurement, equipment speed regulation, and position positioning.

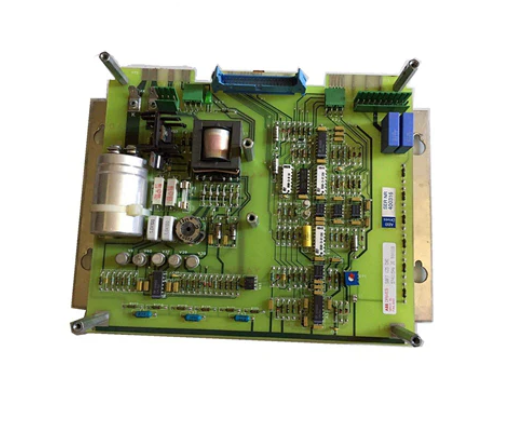

ABB PM820-2 PLC Pulse Counter Module

Product core positioning

The ABB PM820-2 PLC pulse counting module is a functional module designed specifically for industrial automation scenarios. It is an extension component of the AC 800M series PLC and its core function is to accurately collect and process pulse signals output by field devices such as encoders, flow meters, counters, etc., to achieve quantitative monitoring and control of physical quantities such as speed, flow rate, displacement, and output. As an important supporting component of the PM820-1 processor module, it can seamlessly integrate into the AC 800M system, making up for the shortcomings of the main processor in high-frequency pulse signal processing, and providing reliable data support for high-precision industrial control scenarios such as production line measurement, equipment speed regulation, and position positioning.

Key technical parameters

(1) Pulse acquisition core parameters

Count the number of channels

4 independent differential input channels (compatible with single ended input), capable of processing pulse signals from 4 different devices simultaneously

Pulse frequency range

Single channel supports up to 1 MHz high-frequency pulse input, suitable for high-speed rotating equipment such as high-speed encoders and high-frequency flow meters

Counting mode

Supports up counting, down counting, and bidirectional counting modes, which can be flexibly configured through software

Counting accuracy

32-bit unsigned counter, with a maximum count value of 4294967295, to avoid data loss caused by count overflow

Signal input type

Differential RS422/RS485 signal (strong anti-interference ability), single ended TTL signal (compatible with conventional pulse equipment)

Input voltage range

Differential input: ± 5 VDC; Single ended input: 5-24 VDC, compatible with mainstream pulse equipment power supply standards in industrial sites

(2) Basic hardware and communication parameters

Power supply specifications

Input voltage 24 VDC (allowable fluctuation range ± 10%), power consumption ≤ 3 W, compatible with AC 800M system power supply

Size specifications

Width 40mm x height 100mm x depth 160mm, consistent with the size of PM820-1 processor module, compatible with standard 35mm DIN rail installation, saving control cabinet space

Environmental adaptability

Working temperature -25 ° C to+70 ° C, storage temperature -40 ° C to+85 ° C; relative humidity 5% to 95% (no condensation); Anti vibration level IEC 60068-2-6 (10-500 Hz, 10 g acceleration), anti impact level IEC 60068-2-27 (15 g, 11 ms), capable of withstanding harsh environments in industrial sites

Communication interface

1 internal bus interface of AC 800M system, with a data transmission rate of 100 Mbps, communicates in real-time with the main processor and other I/O modules to ensure that pulse data is uploaded without delay

(3) Functional control parameters

Trigger and reset mode

Support three reset methods: software triggering (sending instructions through Control Builder M software), hardware triggering (external reset signal input), and timed reset; Support pulse edge triggering (rising edge, falling edge, double-sided edge), adapted to the signal characteristics of different pulse devices

Alarm function

Equipped with counting overflow alarm, signal loss alarm, and input overvoltage alarm functions, the alarm information is uploaded to the upper computer through the system bus for easy troubleshooting

Filtering function

Configurable 1-100 μ s digital filtering effectively suppresses pulse counting errors caused by electromagnetic interference in industrial sites

Core performance advantages

High frequency pulse precision processing capability: Single channel 1 MHz maximum counting frequency, paired with a 32-bit high-precision counter, can meet the pulse acquisition needs of high-speed equipment (such as motor encoders with over 10000 revolutions per minute), while avoiding numerical overflow caused by long-term counting, ensuring data accuracy.

Strong anti-interference design: adopting differential signal input method, the anti-interference ability is improved by 3-5 times compared to single ended input, which can effectively resist electromagnetic interference generated by industrial field frequency converters, high-power motors and other equipment, and reduce pulse erroneous acquisition; Simultaneously supporting digital filtering function, further filtering high-frequency noise signals.

Flexible functional configuration: Four independent channels can be configured with counting mode, triggering mode, and reset logic respectively, adapting to different types of pulse devices (such as upward counting for flow meters and bidirectional counting for encoders); By using Control Builder M software, parameters can be modified online without the need for power outages or restarts, reducing the impact of operation and maintenance on production.

Seamless system compatibility: Fully compatible with AC 800M series main processors (such as PM820-1) and I/O modules, real-time data exchange is achieved through internal buses, and pulse data can be directly used for logical operations and control instruction execution of the main processor (such as adjusting valve opening based on flow counting and controlling motor frequency based on speed counting), without the need for additional data conversion modules.

High reliability operation: Using industrial grade components, it has undergone wide temperature testing from -40 ° C to+85 ° C and over 100000 vibration and shock tests, with an average time between failures (MTBF) of over 100000 hours; Equipped with a comprehensive alarm mechanism, it can monitor the hardware status and signal abnormalities of the module in real time, facilitating timely troubleshooting.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-