SZ4127.000 is an industrial grade safety door switch, belonging to the ABB safety control component series. Its core positioning is to provide accurate switch signals for the safety control circuit of industrial equipment by monitoring the opening and closing status of the safety door in real time. Its essence is a safety device that combines mechanical and electrical components. When the safety door is in the open state, the internal contacts quickly disconnect, cutting off the dangerous circuit of the equipment or sending a shutdown signal to the controller; When the safety door is fully closed and locked, the contacts can only be closed, allowing the equipment to start running, thereby forcing the safety logic of "the safety door is not closed, the equipment is shut down".

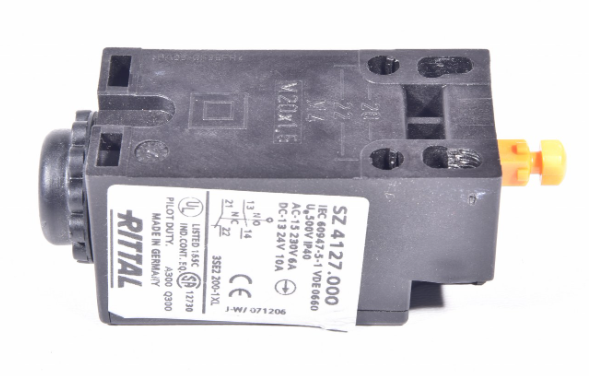

ABB SZ4127.000 door switch

Product positioning and core values

SZ4127.000 is an industrial grade safety door switch, belonging to the ABB safety control component series. Its core positioning is to provide accurate switch signals for the safety control circuit of industrial equipment by monitoring the opening and closing status of the safety door in real time. Its essence is a safety device that combines mechanical and electrical components. When the safety door is in the open state, the internal contacts quickly disconnect, cutting off the dangerous circuit of the equipment or sending a shutdown signal to the controller; When the safety door is fully closed and locked, the contacts can only be closed, allowing the equipment to start running, thereby forcing the safety logic of "the safety door is not closed, the equipment is shut down".

The core value of this product is reflected in three aspects: firstly, by forcibly disconnecting the dangerous circuit, the physical risk of equipment operation when the safety door is opened is eliminated, ensuring the safety of operators; The second is to adopt a high reliability structural design to avoid safety failures caused by contact adhesion and mechanical jamming, and to enhance the stability of the safety circuit; The third is to achieve seamless adaptation with ABB safety relays, PLCs and other control equipment through standardized installation and interface design, reducing the difficulty of system integration.

Core technical functions

The SZ4127.000 door switch integrates ABB's technical accumulation in the fields of industrial safety and mechanical structure design. The functional design closely follows the core requirements of industrial safety, and the core technical functions are as follows:

1. Precise monitoring and signal output of safety door status

The door switch adopts a mechanical linkage structure. When the safety door is opened, the internal cam mechanism drives the contact group to quickly disconnect and output a "door open" signal; When the safety door is closed to the designated position, the mechanical lock tongue resets, the contact group reliably closes, and outputs a "door closed" signal. The contacts are made of silver alloy material, which has excellent conductivity and resistance to arc wear, ensuring precise transmission of switch signals and avoiding signal distortion caused by poor contact of the contacts. At the same time, it supports the combination output of normally closed (NC) and normally open (NO) contacts, which can be flexibly selected according to safety circuit design requirements to meet different control logics.

2. Mandatory locking and anti misoperation function

Equipped with a mechanical locking mechanism, when the safety door is closed, the lock tongue can forcibly lock the safety door in the closed position. Unless a special key or equipment shutdown unlock signal is used, the safety door cannot be forcibly opened, effectively preventing operators from accidentally opening the safety door during equipment operation. Some models support the "unlock delay" function, which means that after the unlock signal is issued, the lock tongue needs to be delayed for a certain period of time (configurable) before it can be released, ensuring that the dangerous parts of the equipment have completely stopped moving before the operator can open the safety door, further enhancing the level of safety protection.

3. High protection and resistance to harsh environments

SZ4127.000 has undergone comprehensive protection design for harsh environments such as dust, oil pollution, humidity, and vibration in industrial sites. The shell is made of high-strength engineering plastic (PA66), which has excellent impact resistance and aging resistance; The sealed structure adopts an IP67 protection level design, which can effectively resist dust intrusion and short-term immersion, and is suitable for dusty and humid environments such as machine tool processing and food processing. The internal mechanical structure adopts anti jamming design, combined with special lubricating grease, which can operate stably in a wide temperature range of -25 ℃~+80 ℃, avoiding mechanical failures caused by environmental factors.

4. Redundant design and security level assurance

The product complies with international safety standards EN ISO 13849-1 (PL d level) and IEC 61508 (SIL 2 level), and adopts a dual contact redundancy design internally. Two sets of independent contacts simultaneously monitor the status of the safety door. Even if one set of contacts fails, the other set can still work normally and provide feedback on the fault information, avoiding safety risks caused by the failure of a single contact. At the same time, the response time for contact disconnection is ≤ 10ms, which can quickly cut off the dangerous circuit and buy time for equipment shutdown.

5. Flexible installation and adaptation capabilities

Support multiple installation methods, including front installation, side installation, and embedded installation, which can adapt to different structures of safety doors and equipment frames; The travel and triggering force of the lock tongue have been optimized and designed to be compatible with safety door panels of different thicknesses (3mm~15mm), without the need for additional adjustments to the mechanical structure. The terminal block adopts a spring or screw design, which is convenient and firm for wiring, supporting wire connections of 1.5mm ²~2.5mm ², and suitable for commonly used cable specifications in industrial sites.

Key technical parameters

Product Model

SZ4127.000

Product Type

Mechanical locking safety door switch

Contact configuration

2 sets of normally closed (NC)+1 set of normally open (NO), dual contact redundant design

Contact capacity

AC 250V/6A,DC 30V/6A

Rated insulation voltage

AC 500V

Action response time

≤ 10ms (contact disconnection time)

security level

EN ISO 13849-1 PL d; IEC 61508 SIL 2

Protection level

IP67 (enclosure), IP65 (terminal block)

Working temperature range

-25℃ ~ +80℃

Adapt to door thickness

3mm~15mm (metal/plastic door panels are acceptable)

locking method

Mechanical tongue lock, supports key unlocking/electrical unlocking

Installation method

Front installation, side installation, embedded installation (with mounting bracket)

wiring method

Screw terminal, supporting wire specifications of 1.5mm ²~2.5mm ²

Shell material

PA66 engineering plastic (flame retardant grade UL94 V-0)

Overall dimensions

Width 65mm, height 105mm, depth 45mm (typical value)

Typical Applicable Scenarios

The SZ4127.000 door switch, with its high safety, reliability, and flexible adaptability, is widely used in various industrial scenarios that require safe isolation. Typical scenarios include:

1. Safety protection of machine tool equipment

Installed on the safety protection door of machine tools such as lathes, milling machines, machining centers, and stamping machines, it is used to monitor the opening and closing status of the protective door. When the operator opens the protective door for tool change, material retrieval, or waste cleaning, the door switch contact immediately disconnects, cutting off the power circuit of the machine tool spindle or slider and forcing the equipment to stop; After the protective door is closed and locked, the contacts are closed, and the equipment can start running, effectively preventing the moving parts of the machine tool from causing injury to the operator.

2. Monitoring of protective barriers for automated production lines

Used to monitor the status of protective barriers or isolation doors in automated production lines such as automotive manufacturing, electronic processing, and food packaging. When maintenance personnel open the protective fence and enter the equipment operation area, the door switch sends a "door open" signal to the PLC or safety relay, and the control system immediately cuts off the operation instruction of the production line, and all actuators stop moving; After maintenance is completed, close the protective fence and lock it. The door switch will provide a "door closed" signal, and the production line can resume operation to avoid personnel entering the dangerous area by mistake.

3. Safety control of lifting and conveying equipment

Install SZ4127.000 door switch on the cab door of the crane, the maintenance door of the winch, and the protective cover of the belt conveyor. When the driver's cab door is not tightly closed or the maintenance door is opened, the door switch cuts off the starting circuit of the equipment to prevent accidental starting of the equipment; For belt conveyors, when the protective cover is opened, the equipment immediately stops to prevent personnel from coming into contact with the running conveyor belt and causing squeezing or scratching accidents.

4. Safety isolation of new energy equipment

Used to monitor the opening and closing status of equipment cabinet doors in new energy equipment such as photovoltaic inverter cabinets, energy storage battery cabinets, and electric vehicle charging piles. When the cabinet door is opened, the door switch disconnects the control signal of the high-voltage circuit, ensuring that maintenance personnel carry out maintenance in an environment without high voltage risks; After the cabinet door is closed and locked, the high-voltage circuit can be powered on to ensure the safety of equipment and personnel.

5. Protection of medical and pharmaceutical equipment

On the isolation doors of sterile workshops in medical equipment (such as MRI machines, disinfection and sterilization equipment) and pharmaceutical production lines, the door switch can achieve interlocking control of equipment operation and door status. When the device is in operation, the isolation door is forcibly locked and cannot be opened; After the equipment is shut down, the door switch is unlocked and the operator can enter, which not only ensures personnel safety but also avoids external interference with the operation status of the sterile workshop or equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-