TK516 is a high-precision contact connection cable designed by ABB specifically for industrial control modules and terminal units. It is a key connecting component of DCS/PLC systems and its core function is to achieve signal transmission and power supply between modules and terminals. It is particularly suitable for the combination application of S500 series I/O modules and TU516 terminal units.

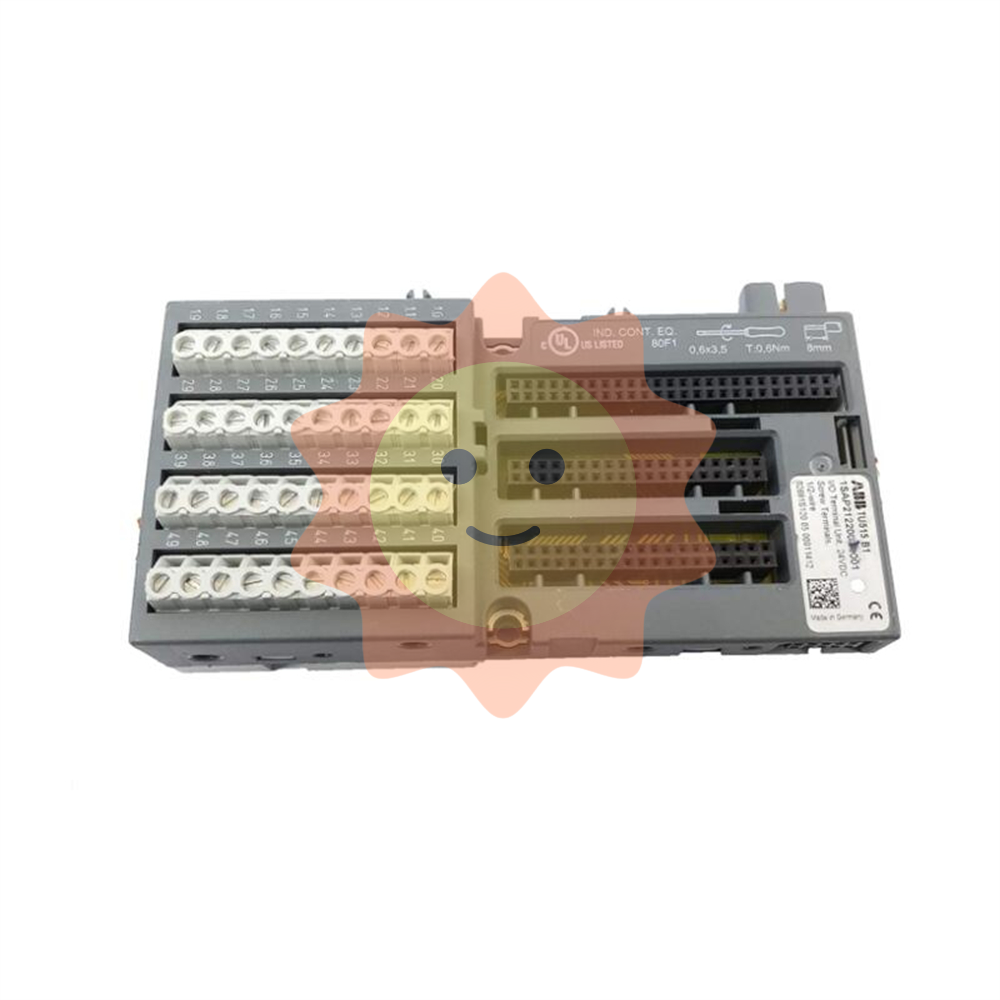

ABB TU515 I/O terminal unit

General Information

Extended Product Type:TU515

Product ID:1SAP212200R0001

ABB Type Designation:TU515

EAN:4016779649223

Catalog Description:I/O terminal unit. For analog and 24 VDC digital modules. Screw terminals (TU515)

Long Description:TU515: S500 I/O terminal unit. For analog and 24 VDC digital modules. Screw terminals.

Ordering

CN8:85389091

Invoice Description:I/O terminal unit. For analog and 24 VDC digital modules. Screw terminals (TU515)

Made To Order:No

Minimum Order Quantity:1 piece

Order Multiple:1 piece

Selling Unit of Measure:piece

Dimensions

Product Net Weight:0.232 kg

Product Net Depth / Length:28 mm

Product Net Height:135 mm

Product Net Width:67.5 mm

Gross Weight:0.262 kg

Package Level 1 Depth / Length:147 mm

Package Level 1 Height:40 mm

Package Level 1 Width:78 mm

Package Level 1 Units:1 carton

Certificates and Declarations

Declaration of Conformity - CE:3ADR980146

REACH Date:20241206

REACH Declaration:3ADR980139

REACH Information:True - contains substances > 0.1 mass percentage

RoHS Declaration:3ADR980146

RoHS Information:Following EU Directive 2011/65/EU and Amendment 2015/863 July 22, 2019

Technical

Function:For analog and 24 VDC digital modules. Screw terminals

Number of Analog Configurable I/Os:0

Degree of Protection:IP20

Supply Voltage:24 V DC

Ambient Air Temperature:

Operation 0 ... +60 °C

Storage -40 ... +70 °C

Additional Information

Product Main Type:TU515

Product Name:

Distributed Automation I/Os

External Classifications and Standards

eClass:27-24-22-92

ETIM 8:EC000810 - PLC mounting rack

ETIM 9:EC000810 - PLC mounting rack

ETIM 10:EC000810 - PLC mounting rack

UNSPSC:32151703

Environmental

WEEE B2C / B2B:Business To Business

WEEE Category:5. Small Equipment (No External Dimension More Than 50 cm)

Product positioning and core values

TU515 is a spring-loaded I/O terminal unit designed by ABB specifically for I/O signal transfer in industrial control systems. It is a key interface component of DCS/PLC systems and its core function is to achieve signal isolation, conversion, and wiring management between external devices (sensors, actuators, etc.) and I/O modules. It is particularly suitable for ABB S500 series I/O modules and is widely used in industrial scenarios such as power, metallurgy, and petrochemicals that require high signal stability and wiring convenience.

Its core value is reflected in * * "signal isolation+convenient operation and maintenance" * *: simplifying complex wiring through modular terminal design, and ensuring long-term connection reliability with built-in spring clamping structure; Support signal grouping isolation, reduce interference between different types of signals, and facilitate later equipment maintenance and module replacement, reducing downtime for maintenance.

Core parameters and structural characteristics

1. Key electrical and physical parameters

parameter category

Specification Details

Terminal type

Spring terminal (no need for screw fastening), compatible with wire specifications of 0.2-2.5mm ² (single/multi stranded tinned copper wire)

Signal compatibility

Supports digital input (DI), digital output (DO), analog input (AI), and analog output (AO) signals, compatible with 24V DC/220V AC signals

Isolation performance

The electrical isolation voltage between adjacent terminal groups is ≥ 500V AC (1 minute), and the signal is isolated from the power circuit to avoid crosstalk

Protection level

IP20 body, adapted to the environment inside the control cabinet; Working temperature -25 ℃ to 70 ℃, storage temperature -40 ℃ to 85 ℃

installation dimensions

Standard DIN rail installation (35mm), width 22.5mm/unit, height 100mm, depth 60mm, suitable for compact cabinet layout

identification system

Clear terminal numbers (such as 1-12) and signal type identification areas are provided on the front, supporting custom label pasting

2. Highlights of structural design

Spring clamping technology: Using high elasticity phosphor bronze springs, the wire is automatically clamped after insertion, with a contact resistance of ≤ 10m Ω and excellent seismic performance (able to withstand 50Hz, 0.5g vibration), avoiding signal interruption caused by loosening of traditional screw terminals.

Group isolation design: Every 6 terminals form a group, with insulation partitions between groups, which can be connected to DI/DO/AI/AO signals separately to prevent analog signals from being interfered by digital signals, especially suitable for high-precision sensor signal transmission (such as RTD temperature signals).

Quick wiring structure: There are wire insertion holes above the terminals, which can be completed without tools; Equipped with test holes, signals can be detected using a multimeter or oscilloscope without disconnecting the wires, improving debugging efficiency.

Module linkage buckle: There is a buckle on the side that matches the ABB S500 series I/O module, which can tightly fix the terminal unit and module on the DIN rail, reduce relative displacement caused by vibration, and ensure signal transmission stability.

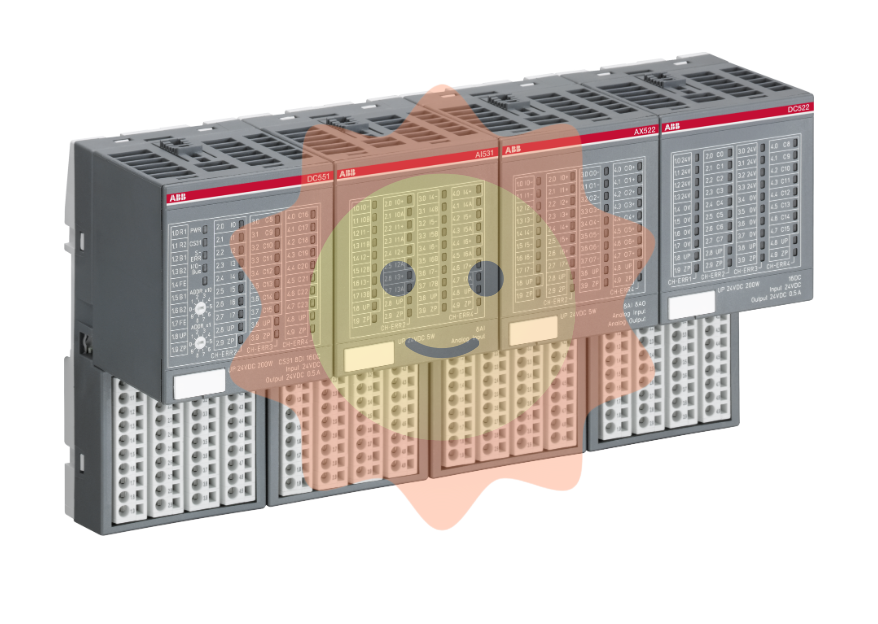

Adaptation devices and collaborative applications

1. Core adaptation equipment

Adapt to device types

Specific model and connection purpose

I/O module

The ABB S500 series (AI810 analog input module, DO810 digital output module, DI810 digital input module) achieves signal transmission through connecting cables

connecting cable

ABB TK516 with contact connection cable (compatible with 3.5mm spacing terminals), TK518 with contact connection cable (compatible with 5.0mm spacing terminals), achieve fast connection between terminals and modules

Industrial Ethernet I/O module

ABB SPCJ4D34-AA, When the module needs to expand external I/O interfaces, signals from devices such as circuit breaker auxiliary contacts and sensors are relayed through TU515

external device

24V DC proximity switch, RTD temperature sensor (such as PT100), relay coil (such as ABB CR-M series), solenoid valve, etc., to achieve signal acquisition and control command output

2. Collaborative application with TK516 cable and SPCJ4D34-AA module

TU515+TK516+S500 I/O module: One end of the TK516 cable is inserted into the "module interface end" of TU515, and the other end is connected to the S500 module. External device (such as sensor) wires are connected to the "external interface end" of TU515, forming a signal transmission link of "external device → TU515 → TK516 → S500 module". The wiring efficiency is improved by 40% compared to traditional manual wiring, and wiring errors are avoided.

TU515+SPCJ4D34-AA module: The SPCJ4D34-AA industrial Ethernet I/O module has 8 DI/4 DO signals, which can be extended to access more external devices (such as multiple circuit breaker auxiliary contacts) through TU515. For example, connect the opening and closing signals of three circuit breakers to the three sets of terminals of TU515, and then aggregate them to the DI interface of SPCJ4D34-AA through TK516 cable to achieve centralized monitoring of multiple device states.

Installation and wiring specifications

1. Installation process

Rail fixation: Insert the TU515 along a 35mm DIN rail, rotate it 90 ° and fix it, ensuring a distance of ≥ 5mm from adjacent devices (such as I/O modules and power modules) for easy heat dissipation.

Module linkage: If used in conjunction with the S500 I/O module, align the buckle on the side of the module with the buckle on the TU515 and press it until it makes a "click" sound to secure the two.

Cable connection: Insert the "terminal end" of TK516 cable into the guide slot of TU515 (corresponding to terminal group 1-6), ensuring that the contacts are fully locked; Insert the cable "module end" into the interface of the S500 module.

External wiring: According to the signal type, strip the external device wire of 5-7mm insulation layer, insert it into the corresponding terminal hole of TU515 (such as DI signal access terminal 1-2, DO signal access terminal 7-8), and gently pull the wire to confirm firmness after insertion.

2. Wiring precautions

Signal grouping: Strictly follow the terminal identification for grouping and wiring, avoid connecting 220V AC signals and 24V DC signals to the same group, and prevent equipment damage caused by voltage breakdown.

Grounding treatment: The shielding layer of analog signals (such as sensor cables) can be connected to the dedicated grounding terminal (usually the last terminal) of TU515, with a grounding resistance of ≤ 1 Ω, to reduce electromagnetic interference.

Polarity differentiation: DC signals (such as 24V DC DI) need to distinguish between positive and negative poles, and connect them according to the terminal identification "+" and "-" to avoid reverse connection and sensor or module burnout.

Overload protection: When connecting high-power actuators (such as solenoid valves), a fuse (such as 5A/250V) should be connected in series between TU515 and the actuator to prevent short circuit damage to the terminals.

Typical application scenarios

Power plant DCS system: In the boiler control system, TU515 is connected to PT100 temperature sensor (AI signal) and S500 AI810 module. Through group isolation design, it ensures that the temperature signal (accuracy ± 0.1 ℃) is not affected by frequency converter interference, ensuring stable control of boiler water temperature.

Petrochemical motor protection system: The SPCJ4D34-AA module is connected to the current transformer signals (AI) and circuit breaker auxiliary contact signals (DI) of three motors through TU515, achieving centralized monitoring of motor overload and grounding faults. The fast wiring characteristics of the terminal unit shorten the on-site debugging time to 2 hours per unit.

Automobile production line: At the robot welding station, TU515 is connected to a 24V DC proximity switch (DI) and S500 DI810 module. The seismic performance of the spring terminals ensures that the signal is not interrupted in welding vibration environments, improving the production line's utilization rate.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-