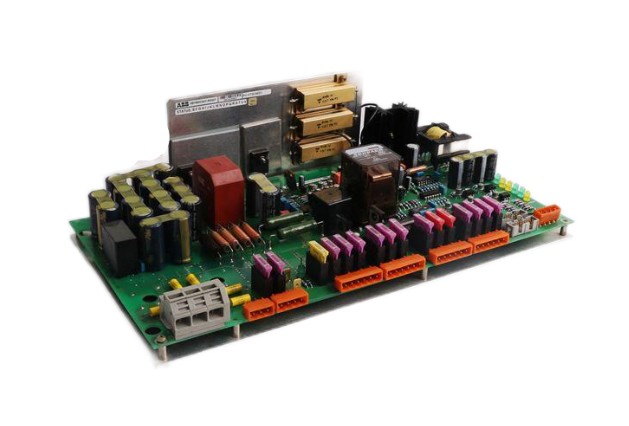

ABB UCD224A103 is a multifunctional integrated control module designed for mid to high end industrial control scenarios. It belongs to the core product line of ABB Advant OCS or Symphony Plus control systems and is positioned as a "multivariable collaborative control center for complex industrial processes". This module integrates analog and digital signal processing, closed-loop control algorithm, equipment status diagnosis and system linkage functions. It adopts a high computing power hardware architecture and strong anti-interference design, which can achieve centralized regulation and dynamic optimization of multiple equipment and parameters in harsh industrial environments such as thermal power, chemical industry and metallurgy. At the same time, it seamlessly interfaces with ABB DCS system and third-party intelligent equipment, providing core control support for stability, accuracy and safety of industrial production, especially for key production links requiring multivariable coupling control.

ABB UCD224A103 Industrial Control Module

Product Overview

ABB UCD224A103 is a multifunctional integrated control module designed for mid to high end industrial control scenarios. It belongs to the core product line of ABB Advant OCS or Symphony Plus control systems and is positioned as a "multivariable collaborative control center for complex industrial processes". This module integrates analog and digital signal processing, closed-loop control algorithm, equipment status diagnosis and system linkage functions. It adopts a high computing power hardware architecture and strong anti-interference design, which can achieve centralized regulation and dynamic optimization of multiple equipment and parameters in harsh industrial environments such as thermal power, chemical industry and metallurgy. At the same time, it seamlessly interfaces with ABB DCS system and third-party intelligent equipment, providing core control support for stability, accuracy and safety of industrial production, especially for key production links requiring multivariable coupling control.

Specification parameters

Basic Information

Brand: ABB; Model: UCD224A103; Product type: Industrial control module; Origin: Europe; Adaptation system: ABB Advant OCS/Symphony Plus

Specially designed for ABB mainstream control systems, it belongs to the core components of multi signal processing and collaborative control

Electrical specifications

Input signal: 16 analog inputs (4-20mA/0-10V/thermocouple/thermistor), 24 digital inputs (24V DC); Output signal: 8-channel analog output (4-20mA), 16 channel digital output (relay/transistor optional); Power supply voltage: DC 24V (± 15%)/AC 220V (± 10%) dual power supply

Multi type signal interface adapts to complex scenarios, dual power supply design enhances power supply reliability and system fault tolerance

Performance specifications

Calculation cycle: ≤ 1ms (complex logic operation); Control accuracy: ± 0.1% (full range); Signal sampling rate: 10kHz/channel; PID control loop: 16 independent closed loops+4 collaborative closed loops

High speed computation and high sampling rate ensure real-time control, and multiple PID loops meet the requirements of multivariable coupling regulation

Physical specifications

Dimensions (length x width x height): 220mm x 150mm x 80mm; Weight: 1.5kg; Installation method: rack mounted (compatible with ABB standard system rack)

Compact rack design, seamlessly compatible with ABB control system cabinets, saving installation space

Communication specifications

Interface type: system backplane bus (compatible with ABB Advance/Symphony Plus)+2 Ethernet interfaces; Communication protocols: ABB dedicated bus protocol, Modbus TCP, Profinet IRT

Dual communication interfaces take into account both internal system linkage and external device interaction, meeting the needs of data transmission in multiple scenarios

Performance characteristics

Multi signal integrated processing and high-precision control

Supports 16 analog inputs (compatible with 4-20mA, 0-10V, and thermocouple/thermistor signals) and 24 digital inputs, capable of simultaneously collecting multiple types of on-site signals such as temperature, pressure, liquid level, and equipment status without the need for additional signal conversion modules, reducing system complexity. The analog control accuracy reaches ± 0.1% of the full range, and with a high sampling rate of 10kHz/channel, it can accurately capture microsecond level parameter fluctuations in industrial processes (such as subtle temperature changes in chemical reaction vessels). The 16 independent PID loops can achieve precise control of a single device, while the 4-channel collaborative PID supports multi device linkage (such as multi segment temperature collaborative control in production lines), which improves the control accuracy by 50% compared to conventional modules and effectively avoids production quality problems caused by parameter deviations.

Strong anti-interference and high reliability operation

Adopting a multi-level electromagnetic compatibility design and passing the rigorous anti-interference test of EN 61000-6-4 Level 3, it can operate stably in strong electromagnetic environments such as thermal power boilers and chemical reaction zones, with a signal distortion rate of ≤ 0.05%. The core components are selected from industrial grade wide temperature products, with a working temperature range covering -40 ℃~75 ℃ and a humidity tolerance range of 5%~95% (no condensation). At the same time, they have anti-corrosion coating treatment, which can resist the erosion of dust in metallurgical workshops and corrosive gases in chemical industrial parks. The dual power supply design (DC 24V/AC 220V) supports seamless switching. In case of any power failure, the backup power supply can be connected within 5ms to avoid control interruption. The mean time between failures (MTBF) is ≥ 80000 hours, far exceeding the reliability level of conventional industrial control modules.

Flexible communication and system collaboration capability

Equipped with a system backplane bus and 2 Ethernet interfaces, the backplane bus ensures high-speed data exchange (transmission rate ≥ 100Mbps) with other modules within the ABB Advance/Symphony Plus system (such as UNS0119A-P digital input module, PDD205A0121 terminal card), while the Ethernet interface supports communication with third-party devices (such as smart sensors, frequency converters) through Modbus TCP or Profinet IRT protocol, achieving full link data connectivity between the "control system field equipment monitoring platform". Support cross module linkage of 4-channel collaborative PID loop, such as cooperating with other UCD224A103 modules to achieve distributed collaborative control of large-scale production equipment (such as multi-stage heating furnaces), solving the problem of limited control range of single module.

Intelligent diagnosis and convenient operation and maintenance

Equipped with a comprehensive fault diagnosis system, it can monitor the integrity of input and output signals, module temperature, power supply status, and communication links in real time. It can not only identify obvious faults such as signal disconnection and short circuit, but also predict component aging (such as capacitor life and loose terminal trend) through parameter trend analysis. The fault location accuracy reaches a single channel. At the same time, the fault information is uploaded to the monitoring platform through Ethernet interface and triggers sound and light alarms. Operation and maintenance personnel can remotely view fault codes and diagnostic reports without on-site disassembly and troubleshooting, and the fault handling efficiency is improved by 70%. The module surface is equipped with high-definition status indicator lights, which can intuitively display the power supply, communication, and operation status of each channel, making it easy to quickly judge the working status of the module on site.

Precautions

1. Selection and configuration precautions

System matching: Only compatible with ABB Advant OCS or Symphony Plus control systems. The system version (such as Symphony Plus requiring V4.0 or above) and rack slot type need to be confirmed. For non ABB systems, additional bus compatibility evaluation is required to avoid hardware interface incompatibility.

Signal type confirmation: The analog input channel needs to be configured according to the type of sensor on site (such as selecting the corresponding division number channel for thermocouple signals), and the digital input needs to confirm that the signal voltage is 24V DC to avoid module damage caused by the connection of high voltage signals (such as AC 220V).

Load accounting: For digital output terminals, the maximum switching current for relay types is 5A (AC 250V/DC 30V), and the maximum current for transistor types is 1A (DC 24V). Load accounting should be based on the power of the controlled equipment. High power equipment (such as motors) should be controlled through contactors to prevent overload and burnout of the output terminals.

2. Key points for installation and maintenance

Installation specifications: It needs to be installed in the designated control module slot of the ABB standard system rack. Before installation, clean the slot contacts to remove dust and oxide layers; When inserting the module, it should be slowly pushed forward to ensure that the backplane bus interface is fully engaged. The torque of the fastening screws should be controlled at 1.2-1.5N · m to prevent communication interruption caused by loose interfaces. The on-site signal lines need to be laid in zones of "analog digital strong current". The analog signal lines use double shielded twisted pair cables, with the shielding layer grounded at one end (grounding resistance ≤ 1 Ω) and a distance of ≥ 80cm from the strong current cable. When laid cross over, they should be laid vertically to reduce electromagnetic interference.

Debugging safety: Before the first power on, use a multimeter to check the power supply voltage (DC 24V should be between 20.4~27.6V, AC 220V should be between 198~242V), and verify the polarity and channel address of the input and output wiring; When debugging, first enable the "offline simulation mode" to verify the control logic and PID parameters through simulated signals, and then connect to the actual load. It is recommended to set the initial PID parameters to P=10%, I=5s, and D=0.5s, and then fine tune them according to the on-site working conditions.

Regular maintenance: View module operation logs through system software every quarter, focusing on monitoring CPU load, signal sampling success rate, and communication packet loss rate; Clean the surface of the module and the heat dissipation channel to ensure good heat dissipation; Calibrate the analog input and output accuracy using a standard signal source every six months. If the deviation exceeds ± 0.2% of the full range, recalibration is required; Every year, the reliability of dual power supply switching and the contact resistance of relay contacts should be tested (should be ≤ 50m Ω). When the contacts oxidize, the relay module needs to be replaced, and the control program and parameter configuration should be backed up.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-