ABB SNAT602 TAC TAC Interface Board is a specialized interface board designed for collaborative interconnection scenarios between industrial control systems. It belongs to the ABB Advant OCS or Symphony Plus control system supporting product line and is positioned as a "bridge for multi system signal interaction and protocol conversion". This interface board focuses on solving the signal compatibility and data exchange problems between different control subsystems (such as TAC building automation system and industrial DCS system) and devices. It integrates multi protocol conversion, signal isolation, and data preprocessing functions, adopts a high stability hardware architecture and anti-interference design, and can achieve bidirectional conversion between TAC protocol and industrial standard protocol in scenarios such as building intelligent control, industrial park comprehensive monitoring, and large-scale public facility automation. It provides reliable interface support for cross system collaborative control (such as building energy management and industrial production energy scheduling linkage), especially suitable for comprehensive automation projects that require multi system integration.

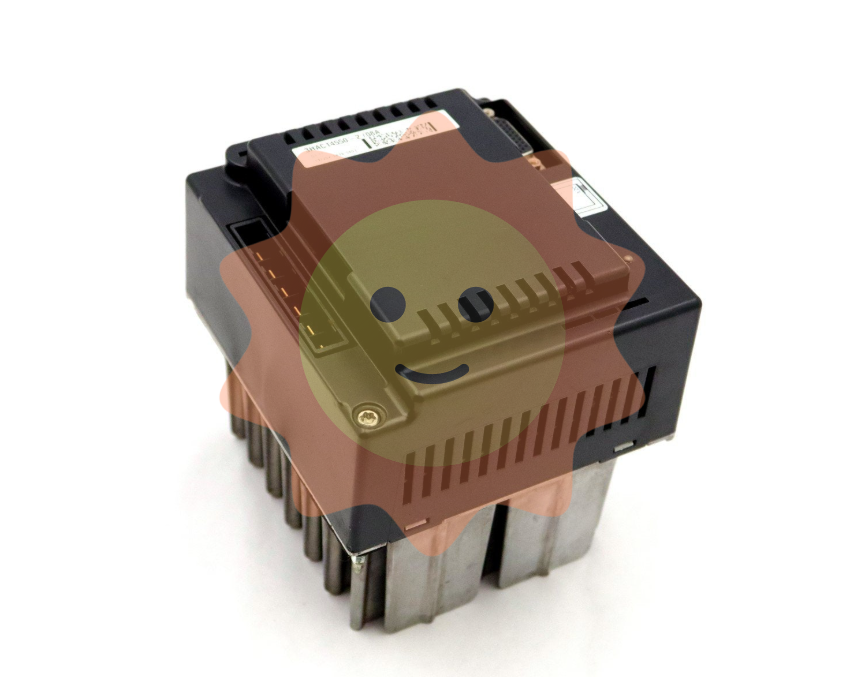

ABB SNAT602TAC Interface Board

Product Overview

ABB SNAT602TAC Interface Board is a specialized interface board designed for collaborative interconnection scenarios between industrial control systems. It belongs to the ABB Advant OCS or Symphony Plus control system supporting product line and is positioned as a "bridge for multi system signal interaction and protocol conversion". This interface board focuses on solving the signal compatibility and data exchange problems between different control subsystems (such as TAC building automation system and industrial DCS system) and devices. It integrates multi protocol conversion, signal isolation, and data preprocessing functions, adopts a high stability hardware architecture and anti-interference design, and can achieve bidirectional conversion between TAC protocol and industrial standard protocol in scenarios such as building intelligent control, industrial park comprehensive monitoring, and large-scale public facility automation. It provides reliable interface support for cross system collaborative control (such as building energy management and industrial production energy scheduling linkage), especially suitable for comprehensive automation projects that require multi system integration.

Specification parameters

Basic Information

Brand: ABB; Model: SNAT602 TAC TAC Interface Board; Product type: TAC dedicated interface board; Origin: Europe; Adaptation System: ABB Advant OCS/Symphony Plus, ABB TAC Building Automation System

Specially designed for ABB TAC protocol and industrial system interconnection, it belongs to the core component of cross system collaboration

Electrical specifications

Signal interface: 2-channel TAC protocol interface (RS485 physical layer), 4-channel industrial standard interface (2-channel RS485, 2-channel Ethernet); Input signal types: TAC protocol signals (such as building temperature and humidity, energy consumption data), industrial standard signals (Modbus RTU/TCP, BACnet MS/TP); Power supply voltage: DC 24V (± 15%)

Multi interface configuration adapts to different system connection requirements, wide voltage power supply enhances scene compatibility

Performance specifications

Protocol conversion delay: ≤ 10ms (TAC) ↔ Modbus TCP); Signal isolation level: Optical isolation between interfaces (2500V AC/1min); Data transmission rate: TAC protocol ≤ 115.2kbps, Ethernet interface ≤ 100Mbps; Data cache capacity: 8MB (supports offline temporary storage)

Low latency ensures real-time data exchange, high isolation avoids interference between systems, and caching function responds to network fluctuations

Physical specifications

Dimensions (length x width x height): 160mm x 120mm x 35mm; Weight: 0.4kg; Installation method: rack mounted (compatible with ABB standard system rack)/rail mounted (compatible with 35mm standard DIN rail)

Compact size suitable for small spaces in control cabinets, dual installation method enhances layout flexibility

Function configuration

Built in protocol conversion engine (supports TAC) ↔ Modbus RTU/TCP、TAC ↔ BACnet MS/TP); Equipped with signal diagnostic indicator lights (protocol operation, data transmission, fault status); Support data filtering and format conversion (such as TAC floating-point data → industrial standard integer data)

Multi protocol conversion covers mainstream scenarios, diagnostic lights display operational status intuitively, and data preprocessing reduces system adaptation costs

Performance characteristics

Bi directional conversion between TAC protocol and industrial standard protocol

Built in dedicated protocol conversion engine, supporting bidirectional real-time conversion between TAC protocol and mainstream industrial standard protocols, among which TAC ↔ Modbus TCP conversion delay ≤ 10ms, TAC ↔ Modbus RTU conversion delay ≤ 5ms, TAC ↔ BACnet MS/TP conversion delay ≤ 8ms, which can meet the real-time data exchange requirements across systems (such as building automation system transmitting real-time energy consumption data to industrial DCS, DCS issuing energy scheduling instructions to building systems). The protocol conversion parameters can be customized through ABB's dedicated configuration software (such as TAC Toolbox), for example, mapping the "building air conditioning unit operating status" in the TAC protocol to Modbus register addresses (0x0001-0x0002) without modifying the original system program, reducing integration complexity.

Multi interface and signal isolation design

Equipped with 2 native TAC protocol interfaces (RS485 physical layer, supporting TAC specific communication protocol) and 4 industrial standard interfaces (2 RS485 for Modbus RTU/BACnet MS/TP, 2 Ethernet for Modbus TCP), it can simultaneously connect TAC building automation systems with multiple industrial subsystems (such as inter vehicle DCS and park energy monitoring systems), achieving "one board connected to multiple systems". The interface adopts optoelectronic isolation technology (isolation voltage 2500V AC/1min), which can effectively block common mode interference between different systems (such as potential difference interference between building weak current systems and industrial strong current systems), with a signal distortion rate of ≤ 0.03%, ensuring the accuracy of cross system data transmission and avoiding system misjudgment caused by interference (such as energy scheduling errors caused by energy consumption data deviation).

Data preprocessing and caching guarantee

Support preprocessing of data before and after conversion, including data filtering (removing instantaneous fluctuation interference, such as jump data of building temperature and humidity sensors), format conversion (such as 32-bit floating-point data of TAC protocol → 16 bit integer data of Modbus protocol, with accuracy retained ± 0.1%), range scaling (such as TAC energy consumption data "kWh" → industrial system "MWh" unit conversion), to reduce the data processing pressure of the receiving end system. Built in 8MB data cache area, when the network is temporarily interrupted (≤ 5 minutes), it can store critical data offline (such as peak energy consumption, equipment failure signals), automatically transmit after network recovery, avoid data loss, and ensure the continuity of cross system data, especially suitable for unstable wireless network scenarios in industrial parks.

Wide environment adaptation and high reliability operation

The core components adopt industrial grade selection, with a working temperature range covering -20 ℃~65 ℃ and a humidity tolerance range of 10%~90% (no condensation), which can adapt to different environments such as building computer rooms, outdoor control cabinets in industrial parks, and weak current rooms in large shopping malls; The shell is made of flame-retardant ABS material (UL94 V-0 grade), which has good dust-proof performance (protection level IP20, can be increased to IP54 with the cabinet). Through EN 61000-6-3 electromagnetic compatibility testing, it can resist electromagnetic interference generated by building variable frequency air conditioning and industrial motors, with an average time between failures (MTBF) of ≥ 120000 hours, far exceeding the reliability level of conventional interface boards and reducing long-term operation and maintenance costs.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-