Watlow 8LS Controller Setup Guide

Communication wiring:

RS-232: Used for point-to-point communication (single controller). The maximum recommended length is 3 meters (at 57.6k baud rate).

RS-485: Used for multi station network systems (up to 32 controllers). It is recommended to use shielded twisted pair cables, and the loop resistance of the transmission line (excluding terminal resistance) should not exceed 200 Ω. A 200 Ω terminal resistor must be installed at the end (farthest end) of the line. Recommend using daisy chain connections to avoid star shaped connections.

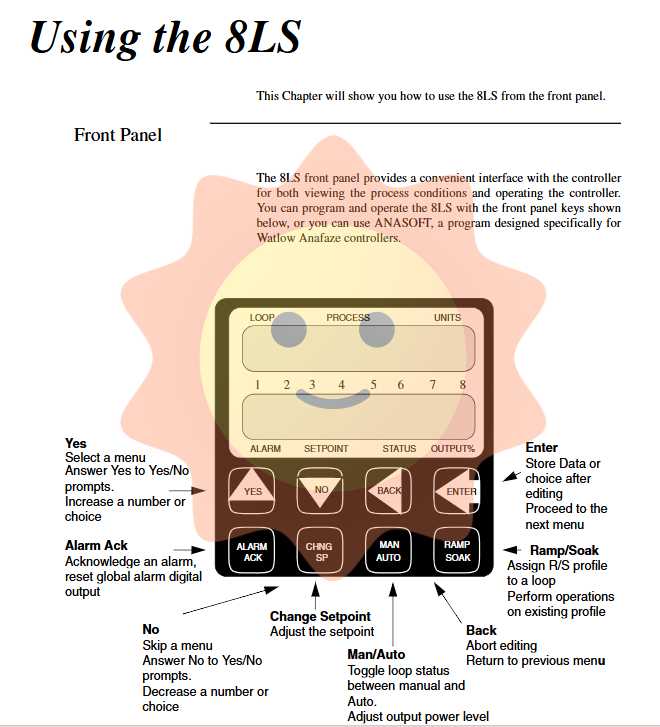

4. Front panel operation and display

The front panel of 8LS provides an intuitive user interface, making it convenient for engineers to directly monitor and operate on site.

Display mode:

Bar chart display: This is the default power on display, providing an overview of the deviation bar chart for all 8 circuits. The upper and lower limits of the bar chart correspond to high/low deviation alarms, with the set point in the middle.

Single loop display: displays detailed information about a specific loop, including process variables (PV), set points (SP), output percentages, and status (manual/automatic/hold).

Scan display: In single loop display mode, press the YES and NO keys simultaneously, and the controller will automatically cycle through the display of single loop information for all activated loops.

Alarm display: When an alarm occurs, the display will automatically switch to alarm mode and flash the alarm symbol. Press the ALARM ACK button to confirm the alarm.

Function of operation keys:

YES/NO key: used for menu navigation, numerical adjustment, confirmation/cancellation of selection.

BACK key: Return to the previous menu or abort the current editing.

ENTER key: Save data or enter the next level menu.

ALARM ACK key: Confirm alarm, reset global alarm digital output.

MAN/AUTO key: Switch between manual and automatic modes, and adjust the output power in manual mode.

RAMP/SOAK key: used to allocate slope/insulation programs to designated circuits (this function needs to be optionally selected).

CHG SP key: Adjust the set point of the current display circuit.

5. System settings and programming

By setting the menu, users can deeply customize various parameters of 8LS. The settings menu is divided into: global parameters, input settings, control settings, output settings, and alarm settings.

Global parameters:

Controller address: In a multi station communication system, each controller needs to set a unique address (1-32).

Communication protocol: Supports ANASOFT or Allen Bradley protocols.

Communication baud rate: 2400 or 9600.

Slope/insulation time base: Set whether the time unit in the program is "hour: minute" or "minute: second".

Panel lock: prevents unauthorized personnel from modifying parameters through panel buttons.

Power on output status: Set whether the output remains disconnected or returns to its original state after power failure and restart.

Input settings:

Input type: Supports J, K, T, E, and N type thermocouples, RTD1/RTD2, Linear and pulse inputs.

Linear scaling: By inputting high and low process variable values and corresponding instrument readings, the input signal is automatically calibrated to engineering units (such as PSI, m ³/h). For example, entering 100 PSI corresponds to 4mA, and 400 PSI corresponds to 20mA.

Thermocouple offset: used to correct nonlinear errors of specific types of thermocouples (such as J-type) at low temperatures.

Control settings:

PID parameters: The proportional band (PB), integral time (TI), and derivative time (TD) of the heating and cooling outputs can be independently set.

Output type

TP (Time Proportional): The output simulates an analog quantity by changing the on-off time ratio within one cycle, commonly used to drive SSRs.

DZC (zero crossing detection): determines the switch state at the zero crossing of each AC line cycle, especially suitable for fast heating loads (such as open coils).

O/F (switch): Simple on-off control.

ANA (Analog): Standard 0-5VDC or 4-20mA continuous signal.

Output limit: Maximum output limit and limit time can be set for "soft start" or limiting energy input.

Alarm settings:

Process alarm: Independent setting of high/low process alarm.

Deviation alarm: Set the width of the deviation band.

Alarm dead zone: prevents process variables from fluctuating near the alarm value, leading to repeated triggering of alarms.

Alarm delay: Set the duration required for alarm activation to avoid false alarms during startup.

6. PID tuning and tuning

8LS provides automatic tuning function, but in specific applications, manual tuning of PID parameters is necessary.

Control mode:

Switch control: The simplest control, which only activates the output when the process variable exceeds the set range. Suitable for systems with high thermal inertia.

Proportional control: The output is proportional to the error, but there is an offset.

Proportional Integral Control (PI): Introducing an integral term to eliminate static errors.

PID control: Introducing differential terms to eliminate overshoot, suitable for responsive systems.

Automatic tuning:

In single loop display mode, select the control mode as "TUNE", press the ENTER key, the controller will output 100%, and then automatically calculate and set the PID parameters. During the calculation period, if the process variable exceeds 75% of the set point or the calculation timeout (10 seconds), automatic tuning will be aborted.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor