The Honeywell 05701-C-0390 interconnect cable is a key accessory designed specifically for connecting industrial automation and complex electronic devices. In the field of industrial automation, from the transmission of basic sensor signals to the interaction of instructions between controllers and actuators, it plays an indispensable bridging role, effectively ensuring the efficient collaboration of various links in the production line. In the process control industries such as chemical and petroleum, it closely connects various monitoring instruments and control equipment, providing support for operators to real-time control production process data and precise regulation, and is an important component to ensure the stable and reliable operation of industrial systems.

Honeywell 05701-C-0390 Interconnection Cable

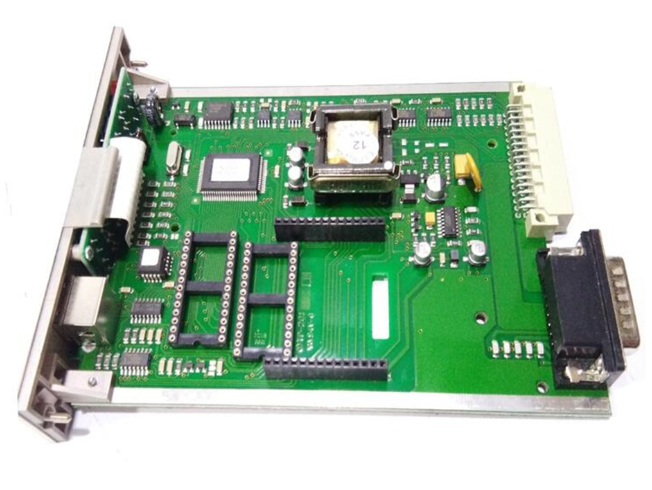

Product Overview

The Honeywell 05701-C-0390 interconnect cable is a key accessory designed specifically for connecting industrial automation and complex electronic devices. In the field of industrial automation, from the transmission of basic sensor signals to the interaction of instructions between controllers and actuators, it plays an indispensable bridging role, effectively ensuring the efficient collaboration of various links in the production line. In the process control industries such as chemical and petroleum, it closely connects various monitoring instruments and control equipment, providing support for operators to real-time control production process data and precise regulation, and is an important component to ensure the stable and reliable operation of industrial systems.

Specification parameters

Wire gauge: Although the wire gauge is not explicitly disclosed, it is speculated that its wire gauge may be in the range of 20AWG-22AWG based on similar products from Honeywell. This standard selection ensures signal transmission efficiency while also being well adapted to common industrial equipment interfaces, meeting the transmission needs of different powers and signal strengths.

Length: There are likely multiple standard length options available, such as 1 meter, 3 meters, etc. Different length settings are designed to meet diverse equipment layout and installation distance requirements, whether it is short distance connection of equipment in compact spaces or long-distance communication between equipment in larger factories, suitable cable lengths can be found.

Number of cores: Currently, the number of cores is unknown, but based on their industrial application scenarios, the number of cores may be reasonably configured according to the type and quantity of transmitted signals to achieve simultaneous transmission of multiple signals such as data and power, meeting the connection requirements of complex industrial systems.

Connector type: To achieve fast and reliable connection, facilitate installation and later maintenance, it may be equipped with customized connectors. These connectors are designed with precision to effectively reduce system failures caused by poor connections, ensuring stable equipment connections and smooth signal transmission.

Performance characteristics

Signal transmission performance: High quality copper conductors are used, and the good conductivity of copper enables high-speed and stable signal transmission, effectively reducing signal attenuation and distortion during transmission, and ensuring accurate communication between devices. Both high-frequency data signals and control signals that require high stability can be accurately delivered to the target device.

Anti interference capability: Given the numerous sources of electromagnetic interference in industrial environments, cables have a multi-layer shielding structure. This design is like putting a sturdy armor on signal transmission, which can strongly resist electromagnetic interference (EMI) and radio frequency interference (RFI). Even in high electromagnetic radiation areas, it can ensure signal stability and lay a solid foundation for the stable operation of industrial control systems.

Durability: The cable sheath is made of durable materials such as polyvinyl chloride (PVC). This type of material not only has excellent resistance to common chemical substances in industrial production, which can prevent cable damage caused by chemical corrosion, but also has oil resistance and can maintain stable performance in oily environments, greatly extending the service life of cables.

Precautions

Installation environment: Avoid installation in extreme high or low temperature environments. The ideal installation temperature range is recommended to refer to the general standard for industrial electronic products, which is about -20 ° C to 50 ° C. Excessive or insufficient temperature may affect the performance of cable materials and signal transmission effects. At the same time, it is necessary to stay away from corrosive chemicals such as strong acids and bases to prevent the outer skin from being corroded and damaging the cable structure.

Connection operation: During installation, it is necessary to strictly follow the operation manual to ensure that the connector is fully compatible with the device interface, avoiding looseness or virtual connection. Incorrect connection can easily cause signal interruption, poor contact, and other issues, affecting the normal operation of the system. If cable splicing is required, professional tools and standard processes should be used to ensure that the electrical performance of the splice is consistent with the overall performance.

Daily maintenance: Regularly inspect the appearance of the cable to see if there are any signs of outer skin damage or aging. If the outer skin is found to be damaged, insulation treatment or cable replacement should be carried out in a timely manner to prevent safety hazards such as short circuits. At the same time, avoid excessive bending or mechanical compression of cables to prevent damage to internal conductors and affect signal transmission.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-