ABB 1MRK002133-ABr02 analog-to-digital module is a high-precision signal conversion and processing unit launched by ABB in the field of industrial automation control. It belongs to the core supporting module of ABB RELION series protection and control equipment. This module focuses on achieving bidirectional precise conversion, real-time acquisition, and reliable transmission of analog and digital signals in industrial sites, providing stable signal interface solutions for protection devices and measurement and control equipment in power systems, industrial control, and other scenarios.

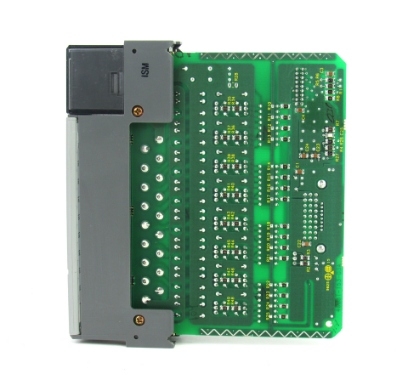

ABB 1MRK002133-ABr02 analog-to-digital module

Product Overview

ABB 1MRK002133-ABr02 analog-to-digital module is a high-precision signal conversion and processing unit launched by ABB in the field of industrial automation control. It belongs to the core supporting module of ABB RELION series protection and control equipment. This module focuses on achieving bidirectional precise conversion, real-time acquisition, and reliable transmission of analog and digital signals in industrial sites, providing stable signal interface solutions for protection devices and measurement and control equipment in power systems, industrial control, and other scenarios.

As a "signal bridge" in industrial automation systems, the 1MRK002133-ABr02 module is identified with 1MRK002133-ABr02 as the core model. It adopts standardized hardware design and modular structure, and can be flexibly integrated into ABB RELION series protection relays and various industrial control systems. It has good compatibility and scalability, and is widely used in fields such as substations, industrial plants, and new energy power stations that require strict signal processing accuracy and reliability.

Core functions and advantages

2.1 High precision signal conversion to ensure data authenticity

The core function of this module is to achieve high-precision conversion between analog signals and digital signals. Its analog input channel can accurately collect continuously changing analog signals such as voltage, current, temperature, pressure, etc. from industrial sites. It is converted into digital signals through a built-in 16 bit high-precision ADC (analog-to-digital converter), with a conversion accuracy of ± 0.1%; At the same time, the digital output channel of the module can convert the digital instructions issued by the control system into corresponding analog signals, drive the actuator to act, and control the digital to analog conversion error within a very small range. This high-precision conversion capability ensures the authenticity of signals during transmission and processing, providing a fundamental guarantee for the accuracy of control decisions.

2.2 Multi channel configuration to meet complex signal requirements

The 1MRK002133-ABr02 module adopts a multi-channel design, usually configured with 4-8 analog input channels, 2-4 analog output channels, and several digital I/O channels (the specific number of channels can be adjusted according to the configuration), which can simultaneously process multiple different types of signals. For example, in a substation scenario, the module can simultaneously collect temperature signals, bus voltage signals, and line current signals from transformers, and upload the processed digital signals to the protection device. At the same time, the receiving device outputs analog signals to control the operation of the voltage regulating device, greatly improving the signal processing efficiency of the system.

2.3 Strong anti-interference ability, adaptable to harsh environments

In response to the complex electromagnetic environment of industrial sites, this module adopts multiple anti-interference designs. At the hardware level, the module is equipped with a built-in signal isolation circuit to achieve electrical isolation between input, output, and power supply. The isolation voltage can reach 2500V AC, effectively suppressing common mode interference and differential mode interference; At the software level, the collected signals are denoised using digital filtering algorithms to eliminate high-frequency interference signals. These designs enable the module to operate stably in harsh environments such as strong electromagnetic radiation and voltage fluctuations, ensuring the reliability of signal transmission.

2.4 Flexible communication and integration capabilities

The module supports internal high-speed bus communication with ABB RELION series protection control devices, while reserving standard external communication interfaces (such as SPI, I2C) for easy access to various industrial control systems. It adopts standardized communication protocols and can quickly exchange data with devices such as PLC and DCS without the need for complex protocol conversion, reducing the difficulty of system integration. In addition, the module supports hot swappable functionality (some configurations), which allows for module replacement without shutting down the system, improving the convenience of system operation and maintenance.

2.5 Comprehensive self diagnosis and protection functions

To enhance operational security, the module is equipped with comprehensive self diagnosis and protection mechanisms. The self diagnostic function can monitor the power status, channel working status, AD/DA conversion circuit status, etc. of the module in real time. When an abnormality is detected, it immediately sends a fault signal to the main controller through the communication bus and lights up the module's own fault indicator light; The protection functions include overvoltage protection, overcurrent protection, short circuit protection, etc. When the input signal exceeds the rated range or the module experiences a short circuit fault, the protection circuit quickly acts to prevent damage to the module and associated equipment.

Key technical parameters

Analog input

4-8 channels, 0-10V DC/4-20mA DC

Supports voltage and current analog signal input, can be configured through jumper wires

Analog output

2-4 channels, 4-20mA DC

Load capacity ≤ 500 Ω, output accuracy ± 0.1%

ADC conversion accuracy

16 bits

The sampling rate can reach 1kHz, meeting the real-time signal acquisition requirements

Isolation level

2500V AC between input/output/power supply, 1 minute

Complies with IEC 61010-1 standard and enhances anti-interference capability

working power supply

24V DC ±20%

Wide voltage input range, suitable for industrial power supply fluctuations

Operating Temperature

-25℃~+70℃

Meet the operational needs of high and low temperature industrial environments

communication interface

Internal high-speed bus SPI

Support seamless communication with RELION series devices

Overall dimensions

Standard 3U rack type (specific subject to physical object)

Adapt to standard industrial control cabinet installation

Applicable scenarios

-Power system substation: integrated into transformer protection devices and line protection devices, collecting signals such as transformer oil temperature, winding temperature, bus voltage, and line current to provide accurate data support for protection logic judgment.

-Industrial automation production line: In chemical, metallurgical, automotive manufacturing and other production lines, various sensor signals (such as pressure, flow, liquid level) are collected, and PLC control instructions are converted into analog signals to drive valve, motor and other actuators, achieving precise control of the production process.

-New energy power station: In photovoltaic and wind power stations, the output voltage and current of photovoltaic modules, the speed and attitude signals of wind turbines are collected, and the processed signals are uploaded to the power station monitoring system. At the same time, control instructions are received to adjust the operating status of power generation equipment.

-Rail transit power supply system: used in the power supply system of subways and light rails to collect the operating parameters of traction inverters (such as output voltage, current, temperature), ensuring the stable operation of the power supply system and rapid response to faults.

-Data center power monitoring: Collect signals such as voltage, current, and charging/discharging status of the UPS power supply and battery pack in the data center to achieve real-time monitoring and fault warning of the power system, ensuring the reliability of power supply in the data center.

Installation and operation precautions

5.1 Installation Requirements

The module needs to be installed in a standard industrial control cabinet, and the installation position should avoid direct sunlight, rainwater splashing, and severe vibration, ensuring good ventilation of the cabinet to meet the heat dissipation requirements. When wiring, it is necessary to strictly distinguish between analog input/output channels and power channels. Analog signal lines should use shielded twisted pair cables and maintain a distance of at least 30cm from power cables to reduce electromagnetic interference; The wiring terminals should be securely fastened to prevent poor contact from causing abnormal signals.

5.2 Daily operation and maintenance

In daily operation and maintenance, it is necessary to regularly check the status of the module's operation indicator lights (power light, operation light, fault light) to ensure that the indicator lights display normally. Check the wiring terminals of the module once a month and tighten any loose terminals; Use specialized tools to clean the dust on the surface of the module and the heat dissipation holes every quarter to prevent dust accumulation from affecting heat dissipation. In addition, it is necessary to regularly verify the channel accuracy of the module through the main controller to ensure that the signal conversion accuracy meets the requirements.

5.3 Fault Handling

When the module fault light is on or the main controller prompts a module fault, the first thing to do is to check whether the module power supply is normal, eliminate the problem of abnormal power supply voltage or loose wiring; If the power supply is normal, specific fault information (such as channel failure, communication failure) can be viewed through the main controller. For channel faults, check whether the signal line wiring and external sensors/actuators of the corresponding channel are normal; For communication failures, it is necessary to check the communication line and bus configuration. If the fault cannot be resolved by oneself, one should contact ABB's official technical support to avoid disassembling the internal components of the module without authorization.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-