The ABB 216AB61 (model name: HESG324013R101) digital output unit is the core execution component in ABB industrial automation control systems. It is mainly used to convert the digital signals of the control system into physical signals that can drive external actuators (such as relays, solenoid valves, indicator lights, etc.), achieving precise control of various equipment in industrial production processes. This unit, relying on ABB's rigorous industrial design standards, has high reliability, strong anti-interference ability, and wide environmental adaptability, and is widely used in fields such as power, metallurgy, chemical, manufacturing, etc. that require extremely high control accuracy and stability.

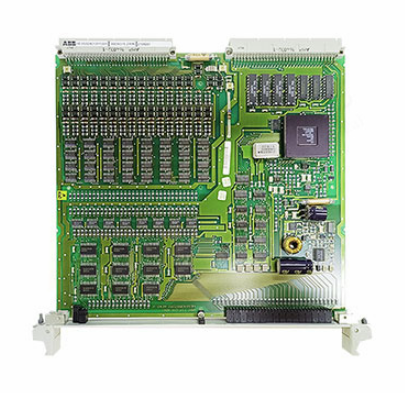

ABB 216AB61 HESG324013R101 digital output unit

Product Overview

The ABB 216AB61 (model name: HESG324013R101) digital output unit is the core execution component in ABB industrial automation control systems. It is mainly used to convert the digital signals of the control system into physical signals that can drive external actuators (such as relays, solenoid valves, indicator lights, etc.), achieving precise control of various equipment in industrial production processes. This unit, relying on ABB's rigorous industrial design standards, has high reliability, strong anti-interference ability, and wide environmental adaptability, and is widely used in fields such as power, metallurgy, chemical, manufacturing, etc. that require extremely high control accuracy and stability.

As an important component of ABB's automation product system, this digital output unit is seamlessly compatible with ABB's PLC, DCS and other control systems. Through standardized interfaces and communication protocols, it builds an efficient and collaborative control network, providing solid support for the automation and intelligent operation of industrial production.

Core functions and advantages

2.1 Core Functions

-Digital signal conversion and output: Receive low-level digital command signals (such as PLC logic signals) from the controller, amplify them through internal driving circuits, and output high-level or switch signals that meet industry standards, directly driving external execution components to achieve precise conversion of "command execution".

-Status monitoring and feedback: Built in output status detection circuit can monitor the working status of each output channel in real time (such as on/off, overload, etc.), and feedback the status information to the controller for system fault diagnosis and maintenance, improving the transparency of the control loop.

-Fault protection mechanism: It has overcurrent protection, short circuit protection, and overvoltage protection functions. When external loads encounter abnormalities (such as short circuits or overloads), the unit can quickly cut off the output circuit to avoid damage to itself and external equipment, and trigger a fault alarm signal.

-Anti interference design: adopting optoelectronic isolation technology and electromagnetic compatibility (EMC) design, effectively isolating electrical interference between input and output circuits, resisting interference factors such as electromagnetic radiation and voltage fluctuations in industrial sites, and ensuring the stability of signal transmission.

2.2 Product advantages

-High reliability: Adopting industrial grade components and modular structure design, it has undergone rigorous environmental tests such as high temperature, low temperature, humidity, and vibration, with a long mean time between failures (MTBF), adapting to complex and harsh industrial site environments.

-Flexible compatibility: Supports direct integration with mainstream ABB control systems such as AC 800M, S400, etc., and is compatible with standard industrial communication protocols, allowing for flexible integration into different automation control architectures and reducing system integration costs.

-Easy to install and maintain: Adopting standardized rail installation method, the wiring terminals are clear and standardized, supporting hot plugging (some models), making it easy to install, debug and maintain on site, reducing downtime.

-Precision control performance: Fast output response speed, low signal delay, can achieve fast and precise control of external devices, meeting the needs of high-precision industrial production processes.

Key technical parameters

output channel

Usually 8 channels/16 channels (subject to actual model)

Multi channel independent control, with channels isolated from each other

output type

Relay output/transistor output

Relay output is suitable for AC loads, transistor output is suitable for DC loads

Output voltage range

DC 24V; AC 110V/220V (matched according to output type)

Support common industrial power specifications and adapt to different load requirements

Maximum output current

Maximum 2A/5A per channel (depending on the model)

Can drive low to medium power industrial actuators

input signal

DC 24V logic signal (high level 11-30V, low level 0-5V)

Compatible with standard PLC/DCS output signals

Isolation method

Optoelectronic isolation, isolation voltage ≥ 2500V AC

Effectively block interference signal transmission

Working environment temperature

-20℃ ~ +60℃

Adapt to wide temperature industrial scenarios

Operating Humidity

5%~95% (non condensing)

Resistant to high humidity environment, avoiding damage to internal components caused by moisture

Protection level

IP20 (Panel Installation)

Suitable for installation environment inside the control cabinet

Overall dimensions

Standard guide rail installation dimensions (such as 120mm × 80mm × 60mm, subject to actual conditions)

Save internal space of control cabinet

Applicable scenarios

This digital output unit plays an important role in multiple industrial fields due to its stable performance and wide compatibility. Typical application scenarios include:

1. Power industry: Used for equipment control in substations and power plants, such as operating mechanisms for driving isolation switches and circuit breakers, as well as start stop control of indicator lights and alarm devices.

2. Metallurgical industry: Adapt to equipment such as rolling mills and furnaces in the production of steel and non-ferrous metals, control the action of hydraulic valves and pneumatic valves, and achieve precise control of the production process.

3. Chemical industry: In chemical reaction vessels and pipeline systems, components such as solenoid valves and regulating valves are driven to control the transportation, mixing, and reaction conditions of materials, ensuring production safety and stability.

4. Manufacturing industry: Used for equipment control in automated production lines, such as the start and stop of conveyor belts, triggering of robotic arm movements, and process switching of processing equipment.

5. Water treatment industry: Control water pumps, gates, disinfection equipment, etc. to achieve automated operation of sewage treatment and water supply systems.

Installation and usage precautions

5.1 Installation specifications

-Before installation, it is necessary to confirm that the unit model matches the control system, check the appearance for any damage, and ensure that the terminals are not loose.

-Installed on a 35mm standard DIN rail, the installation location should be away from high-temperature heat sources, strong electromagnetic interference sources (such as frequency converters), and corrosive gases.

-Ensure good ventilation in the installation environment to avoid performance degradation or damage to the unit due to poor heat dissipation.

-When wiring, it is necessary to strictly distinguish the power terminal, input signal terminal, and output load terminal according to the terminal diagram to avoid reverse polarity or short circuit of the positive and negative poles.

5.2 Use and Maintenance

-Before the first power on, it is necessary to check that the power supply voltage is consistent with the rated voltage of the unit to avoid overvoltage damage to the internal circuit.

-Regularly check the tightness of the wiring terminals to prevent poor contact caused by vibration.

-When a fault alarm occurs, the power should be cut off first, and the fault channel should be located through feedback information from the controller to check whether the external load is abnormal, and then the unit should be tested.

-Dry and clean tools should be used during maintenance to prevent water and dust from entering the interior of the unit.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-