The ABB 216EA61B (complete model: HESG448230R1/G) high-voltage direct current converter valve is the core power conversion equipment in high-voltage direct current (HVDC) transmission systems, responsible for the key task of efficiently converting alternating current energy into direct current energy in both directions. As a representative product of ABB in the fields of flexible direct current transmission (VSC-HVDC) and traditional direct current transmission, this converter valve adopts modular design and advanced power electronics technology, with the characteristics of high voltage, large capacity, low loss, and high reliability. It can accurately control the transmission direction, voltage amplitude, and power size of electrical energy, and is the core equipment for building cross regional, large capacity transmission channels, realizing new energy grid integration and consumption, and grid interconnection.

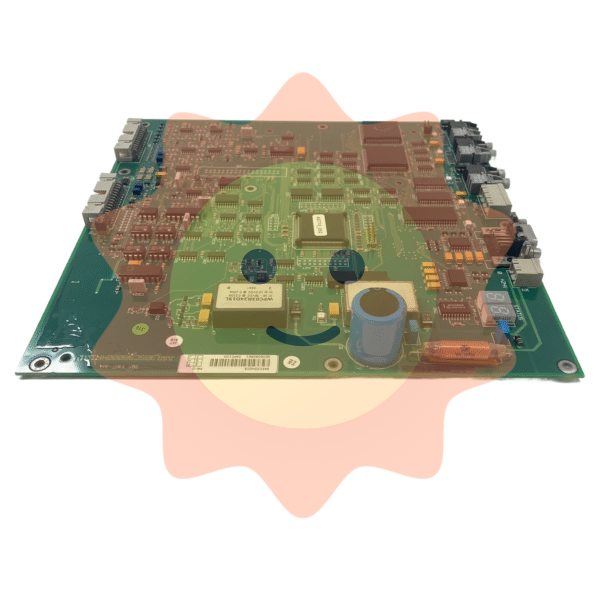

ABB 216EA61B HESG448230R1/G High Voltage DC Converter Valve

Product Overview

The ABB 216EA61B (complete model: HESG448230R1/G) high-voltage direct current converter valve is the core power conversion equipment in high-voltage direct current (HVDC) transmission systems, responsible for the key task of efficiently converting alternating current energy into direct current energy in both directions. As a representative product of ABB in the fields of flexible direct current transmission (VSC-HVDC) and traditional direct current transmission, this converter valve adopts modular design and advanced power electronics technology, with the characteristics of high voltage, large capacity, low loss, and high reliability. It can accurately control the transmission direction, voltage amplitude, and power size of electrical energy, and is the core equipment for building cross regional, large capacity transmission channels, realizing new energy grid integration and consumption, and grid interconnection.

This converter valve fully integrates ABB's profound technical accumulation in the field of power electronics. Its core components and control system are highly coordinated, which can adapt to the dynamic adjustment needs of complex power grid conditions and provide solid guarantees for the safe and stable operation of high-voltage direct current transmission systems. It is widely used in major power projects such as ultra-high voltage direct current engineering, new energy base transmission, urban power grid upgrading, and cross regional power grid interconnection.

Core functions and technical features

2.1 Core Functions

-Bidirectional conversion of AC/DC power: As the "energy conversion center" of the HVDC system, it can achieve rectification conversion of AC energy to DC energy, as well as inversion conversion of DC energy to AC energy, meeting the demand for bidirectional transmission of electrical energy between power grids and enhancing the flexibility of power grid scheduling.

-Precise power and voltage control: With advanced control algorithms built-in, the output power, DC voltage, and AC power factor can be adjusted in real time, quickly responding to changes in grid load and scheduling instructions, maintaining grid voltage stability, and suppressing power fluctuations.

-Fault crossing and self-protection: Equipped with a comprehensive fault detection and protection mechanism, when faults such as short circuits or voltage dips occur in the power grid, protective measures such as current limiting and locking can be quickly activated to prevent the fault from expanding and damaging equipment; Simultaneously supporting quick restart after fault clearance, reducing power outage time in the grid.

-Harmonic suppression and power quality optimization: Adopting a multi-level topology structure and pulse width modulation (PWM) technology, effectively reducing the harmonic components generated during the commutation process, minimizing harmonic pollution to the power grid, and improving the power quality of the transmission system.

-State monitoring and diagnosis: Integrated with a comprehensive state monitoring module, real-time collection of key data such as valve side voltage, current, temperature, insulation status, etc., through data analysis to achieve fault warning and life assessment, providing data support for equipment lifecycle management.

2.2 Technical Characteristics

-Modular and standardized design: using standardized components such as valve modules and cooling modules for easy on-site installation, debugging, and later maintenance and replacement; The modules are independent of each other, reducing the impact of single point failures on the overall system.

-High voltage and large capacity adaptability: High performance insulated gate bipolar transistors (IGBT) or thyristors are used as core switching devices, which can adapt to voltage requirements ranging from hundreds of kilovolts to ultra-high voltage levels. The rated power of a single valve group can reach hundreds of megawatts, meeting the needs of large capacity transmission.

-Efficient and energy-saving features: By optimizing the topology structure and device selection, the conduction loss and switching loss during the commutation process are reduced, and the commutation efficiency can reach over 99%, significantly improving the energy utilization efficiency of the transmission system.

-Strong grid adaptability: With a wide range of voltage and frequency adaptability, it can operate stably in complex working conditions such as weak grids and islanded grids, especially suitable for high proportion new energy grid connection scenarios in new energy (wind power, photovoltaic) bases.

-High insulation and electromagnetic compatibility performance: Adopting reinforced insulation design, the insulation level meets the requirements of high-voltage power grid operation; Through rigorous electromagnetic compatibility (EMC) testing, it can resist electromagnetic interference in the power grid while avoiding interference with surrounding devices.

Key technical parameters

Rated DC voltage

± 200kV/± 320kV/± 500kV (configured according to engineering requirements)

Adapt to high-voltage direct current transmission projects of different voltage levels

Rated DC current

1000A - 3000A

Match the demand for high-capacity power transmission

Rated capacity

200MW -1000MW single valve group

Flexible combination and configuration based on project scale

Core switch device

High voltage IGBT module/thyristor

IGBT is suitable for flexible DC, thyristor is suitable for traditional DC

topological structure

Two level/three-level/modular multilevel (MMC)

MMC structure is currently the mainstream, with better harmonic performance

Conversion efficiency

≥99.2%

High conversion efficiency reduces energy loss

cooling method

Forced air cooling/water cooling

Water cooling is suitable for large capacity, high power density scenarios

Insulation level

Operating impulse withstand voltage: 1200kV (peak); Lightning impulse withstand voltage: 1500kV (peak)

Meet the insulation safety requirements of high-voltage power grid

Control response time

≤10ms

Quickly respond to power grid dispatch and fault regulation needs

Working environment temperature

-25 ℃~+45 ℃ (outdoor installation); 0 ℃~+40 ℃ (indoor installation)

Adapt to different regional climate conditions

Protection level

Outdoor cabinet IP54; Indoor cabinet IP4X

Resist the impact of outdoor environments such as dust, rain, etc

Applicable scenarios

The ABB 216EA61B HESG448230R1/G high-voltage direct current converter valve, as the core equipment of high-voltage direct current transmission systems, is highly compatible with the national energy strategy and the development needs of the power grid, mainly including:

1. Ultra high voltage direct current transmission project: used for national ultra-high voltage backbone networks such as "West East Power Transmission" and "North South Power Supply", to achieve cross regional and large capacity power transmission, and solve the problem of geographical mismatch between energy sources and load centers.

2. Outward transmission of new energy bases: Adapt to the centralized transmission needs of new energy bases such as wind power and photovoltaics, stabilize the volatility and intermittency of new energy generation through flexible DC technology, and ensure efficient grid connection and stable transmission of new energy.

3. Cross regional power grid interconnection: To achieve interconnection between different provincial and regional power grids, improve the interconnection capability and resource optimization level of the power grid, enhance the risk resistance and power supply reliability of the power grid.

4. Urban power grid upgrade and power supply guarantee: used for high-voltage direct current power supply systems in core areas and industrial parks of large cities, to enhance the power supply capacity and quality of urban power grids, and meet high-density load electricity demand.

5. Power supply for isolated islands and remote areas: Provide stable power supply for isolated power grids such as islands and remote mining areas. It can be connected to the main power grid or new energy generation system through direct current transmission to solve the problem of power supply in isolated areas.

6. Special power supply in the industrial field: used for connecting self owned power plants of large industrial enterprises such as metallurgy and chemical industry to the main power grid, or providing stable DC power supply for high energy consuming equipment to enhance the reliability of industrial production electricity.

Structure composition and working principle

5.1 Core Structure Composition

-Valve module: composed of IGBT/thyristor, buffer circuit, voltage equalization circuit, etc., it is the core unit for realizing power conversion. Multiple valve modules are connected in series or parallel to form a converter valve group that meets voltage and current requirements.

-Valve Control System (VCS): As the "brain" of the converter valve, it is responsible for receiving instructions from the upper control system, generating trigger pulses to control the on/off of switch devices, and monitoring the status of the valve module in real time to achieve fault protection.

-Cooling system: including cooling medium (air, deionized water), radiator, circulating pump/fan, etc., used to timely remove the heat generated during the operation of switch devices, ensuring that the equipment operates within the allowable temperature range.

-Insulation support system: composed of insulators, insulation sleeves, etc., providing reliable insulation support for the converter valve, isolating high voltage potential from ground potential, and ensuring the safety of equipment and personnel.

-Monitoring and Diagnostic System: Integrating sensors for voltage, current, temperature, insulation status, etc., real-time collection of equipment operation data, and achieving status assessment, fault warning, and diagnosis through data analysis.

5.2 Working principle

The working principle of this converter valve is based on the on/off control of power electronic switching devices, achieving the conversion of electrical energy from AC to DC:

1. Rectification mode: When the system needs to convert AC power into DC power, the valve control system generates a trigger signal based on the phase of the AC side voltage, controls the IGBT/thyristor to conduct and turn off at a specific timing, and converts the three-phase AC power into stable DC power through rectification topology, which is transmitted to the load end or DC grid through the DC bus.

2. Inverter mode: When it is necessary to convert DC electrical energy into AC electrical energy, the valve control system controls the on/off frequency and duty cycle of the switching devices through PWM modulation and other technologies, inverts DC electrical energy into AC electrical energy that meets the frequency and voltage requirements of the power grid, and realizes the feedback of electrical energy to the AC power grid or the supply of AC loads.

3. Dynamic adjustment: During operation, the valve control system receives real-time power grid dispatch instructions and its own status monitoring data. By adjusting the trigger pulse parameters, it dynamically adjusts output power, voltage, and other parameters to maintain stable system operation and respond to changes in power grid conditions.

Installation and operation maintenance precautions

6.1 Installation specifications

-Before installation, a detailed on-site investigation is required to ensure that the installation site meets the equipment's requirements for space, temperature, humidity, ventilation, and load-bearing capacity. Outdoor installation should consider measures to prevent wind, rain, and ice and snow.

-Equipment transportation and lifting must be strictly carried out in accordance with operating procedures, avoiding severe impact and vibration, and preventing damage to insulation components; Precision components such as valve modules need to be transported and stored in specialized protective packaging.

-During the installation process, it is necessary to strictly control the cleanliness of the insulation components to avoid dust and oil contamination of the insulation surface, which may affect the insulation performance; The wiring must be securely fastened to avoid local overheating caused by poor contact.

-Before installing the cooling system, pipeline flushing and sealing testing must be carried out to ensure that the cooling medium circuit is leak free and free of impurities; The installation of the insulation support system must ensure levelness and verticality, and ensure even force distribution.

-After installation, a series of debugging work such as insulation resistance testing, DC withstand voltage testing, and control circuit joint debugging are required to confirm that the equipment performance meets the design requirements before it can be put into trial operation.

6.2 Key points of operation and maintenance

-Daily monitoring: Real time monitoring of the operating parameters of the converter valve (voltage, current, temperature, power, etc.) through the converter station monitoring system, with a focus on abnormal parameter fluctuations and timely investigation of the causes.

-Regular maintenance: According to the maintenance manual, regularly replace the medium and clean the filter of the cooling system; Clean and test the insulation performance of insulation components; Check the fastening status and heating condition of the wiring terminals.

-Fault handling: When the equipment malfunctions and alarms, the emergency plan should be immediately activated. The fault module should be located through the monitoring system, and isolation, maintenance, or replacement should be carried out while ensuring safety; After troubleshooting, comprehensive testing is required before resuming operation.

-Spare parts management: Establish a reserve library of key spare parts (such as valve modules, IGBT devices, sensors, etc.) to ensure the quality and availability of spare parts and shorten the time for fault repair.

-Technical file management: Complete recording of equipment installation and commissioning data, operating parameters, maintenance records, fault handling, etc., providing a basis for equipment lifecycle management and performance evaluation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-