The ABB 216VC62A (complete model: HESG324442R112/F) signal digital processor is a key data processing unit in ABB industrial automation control systems. Its core function is to real-time collect, filter, calculate, convert, and logically process various analog and digital signals in the industrial field, converting raw signals into precise data that can be recognized and utilized by the control system, providing core data support for equipment control, status monitoring, and fault diagnosis.

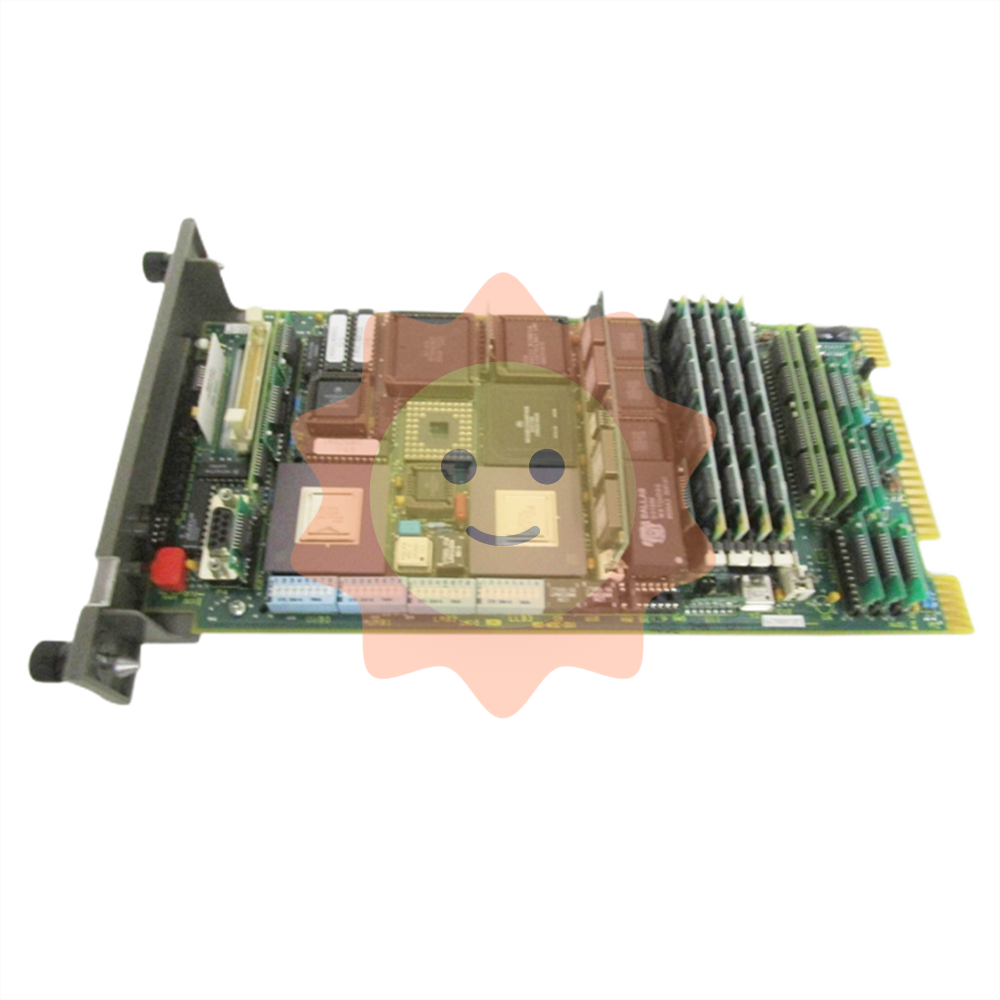

ABB 216VC62A HESG324442R112/F Signal Digital Processor

Product Overview

The ABB 216VC62A (complete model: HESG324442R112/F) signal digital processor is a key data processing unit in ABB industrial automation control systems. Its core function is to real-time collect, filter, calculate, convert, and logically process various analog and digital signals in the industrial field, converting raw signals into precise data that can be recognized and utilized by the control system, providing core data support for equipment control, status monitoring, and fault diagnosis.

This processor integrates high-precision signal conditioning technology and high-performance digital computing core, with the characteristics of fast signal processing speed, high data accuracy, and strong anti-interference ability. It can seamlessly integrate with ABB mainstream PLCs (such as AC 500 series), DCS (such as 800xA system), and various sensors and actuators, and is widely used in industrial scenarios such as power, metallurgy, chemical, and intelligent manufacturing that require strict real-time and reliability signal processing.

Core functions and technological advantages

2.1 Core Functions

-Multi type signal compatible acquisition: supports synchronous acquisition of analog signals (such as 4-20mA current signals, 0-10V voltage signals), digital signals (such as switch signals, pulse signals), and frequency signals, suitable for various industrial sensor output signals such as temperature, pressure, flow rate, liquid level, etc. A single module can achieve multi-channel parallel acquisition.

-High precision signal conditioning and filtering: Built in programmable gain amplifier (PGA) and multi-stage digital filtering algorithms (such as low-pass filtering and Kalman filtering) can effectively suppress electromagnetic interference, noise interference, and signal drift in industrial sites, accurately amplify and purify weak signals, and ensure the stability and accuracy of data acquisition.

-Real time digital computation and logic processing: Equipped with a high-performance 32-bit embedded processor, it supports arithmetic operations (addition, subtraction, multiplication, division, integration, differentiation), logical operations (AND/NOR, XOR), and custom algorithms (such as PID operations and trend analysis), with computation cycles as low as microseconds, meeting real-time control requirements.

-Signal conversion and protocol adaptation: It can convert processed digital signals into communication protocols that comply with industry standards (such as PROFINET, EtherNet/IP, Modbus TCP), enabling data exchange with upper level control systems; Simultaneously supporting the conversion of digital signals into analog or pulse signals for output, driving actuator actions.

-Fault diagnosis and self verification: It has channel fault detection (such as disconnection and short circuit), signal over range alarm, and module self verification functions, which can monitor its own operating status and input signal integrity in real time. The fault information is fed back to the control system through the communication interface, making it easy to quickly locate the problem.

-Data storage and logging: Built in non-volatile memory, capable of caching critical processing data, fault logs, and operating parameters. Data is not lost after power failure, providing a basis for device operation traceability and fault analysis.

2.2 Technical advantages

-High processing accuracy and speed: The analog acquisition accuracy can reach ± 0.1% FS, and the digital processing delay is ≤ 10 μ s, meeting the requirements of high-precision closed-loop control and fast response scenarios.

-Strong anti-interference performance: adopting optoelectronic isolation (isolation voltage ≥ 2500V AC), electromagnetic shielding and power filtering technology, passing IEC 61000-4 series electromagnetic compatibility testing, it can resist common mode interference and differential mode interference in industrial sites.

-Flexible programmability: Supports customizing signal processing logic, computational algorithms, and communication parameters through ABB's dedicated programming software (such as Control Builder M) to meet personalized needs in different industrial scenarios.

-High reliability and stability: Adopting industrial grade components and fanless cooling design, it is suitable for harsh industrial environments such as wide temperature, high humidity, and vibration, with an average time between failures (MTBF) of ≥ 100000 hours.

-Convenient system integration: adopting standardized rail installation method, supporting hot plugging (some models), modular design of wiring terminals, which can quickly connect with existing automation systems and reduce integration costs.

Key technical parameters

Input channel

Analog quantity: 8/16 channels; Digital quantity: 16/32 channels; Frequency: 4/8 channels

Multi channel combination configuration, supporting mixed signal types

Analog input range

Current: 4-20mA, 0-20mA; Voltage: 0-5V, 0-10V, ± 5V, ± 10V

Adapt to mainstream industrial sensor output signals

Accuracy of analog quantity acquisition

±0.1% FS(25℃),±0.2% FS(-10℃~+60℃)

Maintain high-precision acquisition within a wide temperature range

Digital input type

PNP/NPN compatible, with optional dry/wet contacts

Adapt to different types of switches and sensor signals

Frequency input range

0.1Hz - 100kHz

Can collect frequency related signals such as rotational speed and flow rate

Processor core

32-bit ARM Cortex-M4, clock frequency ≥ 120MHz

Provide powerful computational processing capabilities

Calculation cycle

Basic operations ≤ 1 μ s, complex algorithms ≤ 10 μ s

Meet the fast response requirements of real-time control

communication interface

1 x PROFINET, 1 x EtherNet/IP, 2 x RS485 (Modbus RTU)

Supports multiple industrial communication protocols for easy system interconnection

Output signal type

Analog quantity: 4-20mA/0-10V (4-channel); Digital quantity: PNP output (8 channels)

Can directly drive actuators or provide feedback control signals

Power demand

DC 24V ± 10%, power consumption ≤ 15W

Adapt to industrial standard DC power supply

Working environment temperature

-20℃ ~ +60℃

Adapt to extreme industrial environments such as severe cold and high temperatures

Protection level

IP20 (Panel Installation)

Suitable for installation inside control cabinets

Overall dimensions

140mm (width) × 110mm (height) × 120mm (depth)

Standardize dimensions to save control cabinet space

Applicable scenarios

The ABB 216VC62A signal digital processor is widely used in various industrial automation scenarios due to its multifunctional integration, high reliability, and flexible adaptability. Typical scenarios include:

1. Process control field: In the control systems of reaction vessels and distillation towers in industries such as chemical, petroleum, and pharmaceutical, key process parameters such as temperature, pressure, liquid level, and flow rate are collected, and PID closed-loop control is achieved through real-time calculation to accurately adjust valve opening, pump speed, etc., ensuring stable process parameters.

2. Power system monitoring: Collect electrical parameters such as voltage, current, and power factor in substations and power plants, analyze the operation status of the power grid through data calculation, provide data support for load regulation and fault warning, and ensure the stable operation of the power system.

3. Intelligent manufacturing and production line control: In automated production lines such as automotive manufacturing and electronic processing, equipment operating parameters (such as motor speed, robotic arm position) and product detection signals are collected, and process linkage, quality inspection, and fault shutdown control of the production line are achieved through logical operations.

4. Metallurgy and building materials industry: In the blast furnace control system of steel plants and the rotary kiln control system of cement plants, signals such as furnace temperature, material level, and gas composition are collected to optimize production processes through complex algorithms, improve product quality, and reduce energy consumption.

5. New energy equipment control: In wind power and photovoltaic inverter systems, signals such as wind speed, light intensity, and DC bus voltage are collected, and power output is adjusted through real-time calculation to achieve efficient grid connection and stable operation of new energy generation.

6. Equipment status monitoring and diagnosis: In the predictive maintenance system of large rotating equipment such as fans, pumps, compressors, etc., vibration, temperature, noise and other signals are collected, and potential equipment faults are identified through algorithms such as spectrum analysis and trend judgment, and maintenance warnings are issued in advance.

Structure composition and workflow

5.1 Core Structure Composition

-Signal input module: composed of analog input circuit, digital input circuit, and frequency input circuit, responsible for receiving external sensor signals and converting them into weak current signals recognizable by the processor through signal conditioning circuit.

-Core processing unit: With a 32-bit embedded processor as the core and high-speed memory (RAM/ROM), it is responsible for performing core tasks such as signal filtering, arithmetic processing, and logic judgment, and is the "arithmetic center" of the processor.

-Signal output module: It includes analog output circuits and digital output circuits, which convert processed digital signals into physical signals to drive external actuators or communicate with other devices.

-Communication module: integrates multiple industrial communication interfaces and protocol stacks to achieve data exchange with upper level control systems (such as PLC, DCS) and other intelligent devices, supporting data upload and instruction reception.

-Power module: converts industrial DC 24V power supply into stable voltage required by various modules inside the processor, and has overvoltage and overcurrent protection functions to ensure safe power supply for the equipment.

-Diagnosis and indication module: including LED status indicator lights (power, operation, fault) and fault diagnosis circuit, providing real-time feedback on equipment operation status for on-site personnel to quickly troubleshoot problems.

5.2 Workflow

The workflow of this signal digital processor follows the core logic of "signal acquisition conditioning filtering operation processing data output", and the specific steps are as follows:

1. Signal acquisition: The raw signals (analog/digital) output by external sensors (such as temperature sensors and pressure transmitters) enter the signal input module through input terminals to complete the initial signal connection.

2. Signal conditioning and filtering: The original signal is amplified by a programmable gain amplifier (PGA) and converted from analog to digital by an ADC (analog-to-digital converter); Meanwhile, digital filtering algorithms suppress noise and interference in the signal, purifying the effective signal.

3. Digital operation and processing: The core processing unit calls preset algorithms (such as arithmetic operation, logical judgment, PID operation) to process the purified digital signal, generate control instructions or monitoring data.

4. Data output and interaction: The processed results are output in two ways: one is to convert them into analog or digital signals through the signal output module to drive the actuator action; The second is to upload data to the upper control system through the communication module, achieving data sharing and remote monitoring.

5. Status monitoring and diagnosis: Throughout the entire working process, the diagnostic module monitors the real-time operation status of each module and the integrity of input and output signals. If a fault is detected (such as signal over range or communication interruption), it immediately triggers a fault alarm and records a log, while also prompting through LED indicator lights.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-