ABB 3ASC25H705/7 is a high-end control module for precision control of heavy industrial equipment, belonging to the ABB industrial automation core control component series. Its core functions include equipment operation logic calculation, multi loop collaborative control, real-time status monitoring, and emergency fault handling. Its design focuses on high load carrying capacity and extreme environmental adaptability, specifically designed for large units in fields such as power, metallurgy, and heavy manufacturing (such as motor drive systems, steel rolling equipment, and large pump sets). It can be seamlessly integrated into ABB AC800M DCS or dedicated control system architecture, especially suitable for heavy-duty industrial scenarios with strict requirements for control response speed and load driving capability.

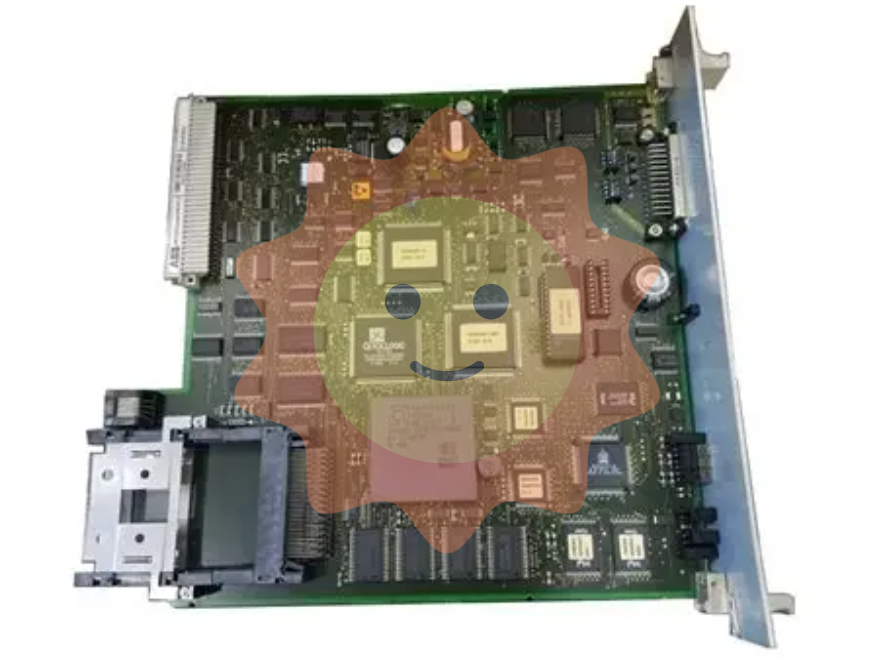

ABB 3ASC25H705/7 control module

Product core positioning

ABB 3ASC25H705/7 is a high-end control module for precision control of heavy industrial equipment, belonging to the ABB industrial automation core control component series. Its core functions include equipment operation logic calculation, multi loop collaborative control, real-time status monitoring, and emergency fault handling. Its design focuses on high load carrying capacity and extreme environmental adaptability, specifically designed for large units in fields such as power, metallurgy, and heavy manufacturing (such as motor drive systems, steel rolling equipment, and large pump sets). It can be seamlessly integrated into ABB AC800M DCS or dedicated control system architecture, especially suitable for heavy-duty industrial scenarios with strict requirements for control response speed and load driving capability.

Key technical parameters (multi-source integration and core specifications)

parameter category

specific parameters

Explanation and application adaptability

Physical specifications

Size: 190 × 130 × 45mm (standard size for industrial heavy-duty modules)

Suitable for 19 inch standard cabinets with reinforced mounting holes and anti vibration design

Weight: Approximately 1.5kg to 2.0kg

Equipped with metal shielding shell and heat dissipation structure, suitable for heavy equipment installation requirements

Electrical performance

Working voltage: 24V DC (± 20% fluctuation compatible)

Wide voltage range to adapt to unstable power sources in industrial sites, ensuring stable power supply under heavy load conditions

Power consumption: normal operation ≤ 30W, peak value ≤ 45W

Adapting to high computing power requirements, the matching heat sink can cope with continuous high load operation

control ability

Digital input: 16 channels, 24V DC (PNP/NPN compatible)

High density input channel, response time ≤ 0.5ms, suitable for multi-sensor signal acquisition

Digital output: 8 channels, 24V DC (maximum load current 5A/channel)

High load output capability, can directly drive medium-sized relays and contactors without power amplification

Analog input: 8 channels, supporting 0-10V DC, 4-20mA

16 bit AD conversion accuracy, acquisition error ≤ ± 0.05% FS, suitable for precision signals such as pressure and temperature

communication capability

Interface type: 2 x Ethernet (Profinet/Modbus TCP), 1 x RS-485

Dual Ethernet redundancy design, with a maximum communication speed of 1Gbps, ensuring seamless transmission of control instructions without delay

Communication delay: Ethernet ≤ 0.5ms, RS-485 ≤ 8ms

Meet the real-time control requirements of overloaded devices and adapt to multi device collaborative scenarios

environmental adaptability

Working temperature: -40 ° C to+75 ° C

Ultra wide temperature design, capable of handling extreme environments such as high temperatures in metallurgical workshops and low temperatures in mines

Protection level: IP20 (requires cabinet installation)

The metal shielding shell meets the EN 55022 standard and has excellent electromagnetic interference resistance

Vibration resistance level: IEC 60068-2-6 (10-500Hz)

Can withstand continuous vibration during the operation of heavy equipment, ensuring signal stability

Reliability indicators

Mean Time Between Failures (MTBF): ≥ 150000 hours

Heavy duty industrial grade reliability reduces the risk of unplanned downtime for large equipment

Core functions and advantages

Heavy load precise driving and control

The maximum load current of a single digital output channel can reach 5A, which can directly drive heavy-duty actuators such as steel rolling equipment contactors and large pump relays without the need for additional intermediate relays, simplifying control circuit design; Combined with 16 bit high-precision analog input, it can capture real-time operating parameters of heavy-duty equipment (such as motor current, bearing temperature), and achieve closed-loop adjustment of parameters such as speed and pressure through built-in PID algorithm, with a control accuracy of ± 0.1%, suitable for precision requirements such as steel rolling thickness control and pump pressure stability.

Multi system collaboration and redundancy guarantee

Support Profinet and Modbus TCP dual protocol communication, seamlessly integrate with ABB AC800M DCS, Siemens S7-400 PLC, and third-party heavy-duty equipment controllers, and achieve cross system equipment linkage (such as coordination between rolling mills and conveyor rollers in metallurgical production lines); The dual Ethernet interface supports redundant configuration. When the main communication link fails, it automatically switches to the backup link within 0.1ms, and with module level hot swapping function, it ensures uninterrupted overload production process.

Comprehensive fault diagnosis and safety protection

Built in hardware level fault self detection module, which can monitor input and output channels, power supply voltage, and communication link status in real time. It generates exclusive codes for more than 20 types of faults such as overcurrent, overvoltage, and signal disconnection, and dual alarms through indicator lights and communication interfaces; Equipped with output channel short circuit protection function, it can instantly cut off the output circuit when the load is short circuited, avoiding damage to the module and external heavy-duty equipment, in compliance with IEC 61508 SIL 2 functional safety standard.

Structural design for overloaded scene adaptation

Adopting a metal shielding shell and reinforced terminal blocks, it can resist industrial dust, oil pollution, and electromagnetic interference (such as strong electromagnetic pulses generated by motor start-up); The module integrates high-density heat sinks at the bottom, combined with natural convection heat dissipation design, which can maintain an internal temperature of ≤ 65 ° C under a peak power consumption of 45W, suitable for high-temperature and dusty heavy-duty environments such as metallurgy and mining.

Flexible configuration and engineering adaptation

Compatible with ABB Control Builder M programming software, supports multiple programming methods such as ladder diagram (LD) and structured text (ST), and can customize control logic for heavy-duty equipment characteristics (such as speed grading adjustment program for steel rolling equipment); Supporting online parameter modification and program download, configuration updates can be completed without power outage, greatly reducing the debugging and maintenance time of overloaded devices.

Typical application scenarios

Metallurgical industry: precision control of rolling mill roll gap (adjusting hydraulic valve through analog output), closed-loop control of heating furnace temperature, coordinated speed of steel strip conveyor line (driving variable frequency motor with digital output)

Power industry: Start stop control of large induced draft fans/supply fans (high load digital output driven contactors), pressure regulation of boiler feedwater pumps, monitoring of cooling system status of generator sets

Heavy duty manufacturing: Shield tunneling machine propulsion speed control (analog output regulating hydraulic pump), crane lifting mechanism load monitoring (analog input collecting tension signal), large machine tool spindle speed regulation

Mining industry: logic control of mine hoist start stop, pressure stabilization of mining pump group (PID closed-loop control), monitoring of crusher operation status and fault alarm

Petrochemical industry: speed regulation of large compressors (analog output control frequency converter), load monitoring of reaction kettle stirring motor, coordinated control of oil pipeline pump group

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-