ABB TP830 is a multifunctional control component designed for industrial automation scenarios. It can be divided into two core forms based on application focus, and should be distinguished from derivative models

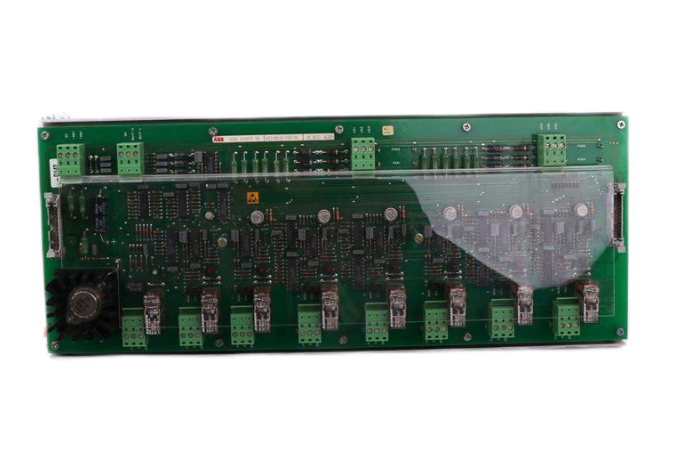

ABB TP830 Industrial Automation Control Module

Product Core Positioning and Form Analysis

ABB TP830 is a multifunctional control component designed for industrial automation scenarios. It can be divided into two core forms based on application focus, and should be distinguished from derivative models

PLC control unit

As the core module of a compact programmable logic controller, it undertakes precise control functions of equipment and processes, represented by the model 3BSE018114R1, and is the control center of small and medium-sized automation systems.

Industrial touch screen

Focusing on human-computer interaction function, device monitoring and operation control are achieved through high-definition touch interface, with strong anti-interference ability and adaptability to harsh environments in multiple industries.

Derivative model TP830-1

Dedicated digital I/O interface module, providing 16 digital input channels, focusing on signal acquisition and transmission, SKU number 3497452.

Key technical parameters and performance advantages

(1) Basic Physics and Electrical Parameters

Parameter category

Core Indicator (TP830 Basic Type)

TP830-1 derivative supplement

Size and weight

Weight 0.234kg, compact design

Same basic type, suitable for narrow installation space

Power supply specifications

Input/output voltage 24VDC, current 500mA

12-24VDC wide voltage compatible

Environmental adaptability

Working temperature -40 ° C to+70 ° C, resistant to harsh working conditions

-25 ° C to+60 ° C, suitable for indoor and outdoor scenes

Communication interface

Ethernet and RS485 dual interfaces

Supports Modbus protocol

(2) Core performance advantages

High reliability design

Using high-quality and durable materials, it can resist interference such as industrial dust and vibration, and has a long average time between hardware failures, reducing the risk of equipment downtime.

Flexible scalability

The modular structure supports seamless integration with other ABB PLC systems, and the 16 channel design of TP830-1 can expand signal acquisition capabilities as needed.

Usability optimization

The operation interface is intuitive, the installation and configuration process is simplified, and there are complete technical documents and training resources to reduce the threshold for operation and maintenance.

Typical application scenarios and industry adaptation

(1) Core application areas

Process industry

In the petrochemical and chemical industries, it is used for the start stop control and operation parameter monitoring of equipment such as compressors and reaction vessels to ensure process stability.

Discrete Manufacturing

Adapt to automotive parts and electronic component production lines, achieve equipment linkage control through PLC function, and provide visual management of production rhythm through TP830 touch screen.

Energy industry

Used for status monitoring and load regulation of generator sets and transformers in the power system, with a wide temperature design suitable for outdoor substation environments.

Basic Industry

The control of rolling mills and water pumps in the steel industry, as well as the automation process scheduling of food processing production lines, have all been maturely applied.

(2) Scenario adaptation case

Small and medium-sized production line control: TP830 PLC unit+TP830-1 I/O module combination, realizing 16 channel sensor signal acquisition and actuator control, with controllable cost and fast response.

Remote device monitoring: With the help of Ethernet interface connected to the industrial Internet of Things platform, the touch screen displays real-time device operation curves and supports fault alarm push.

Selection and usage precautions

Principle of model differentiation

Priority should be given to TP830 PLC unit (3BSE018114R1) for control functions

TP830 touch screen requires human-machine interaction and mutual selection

TP830-1 module needs to be selected for expanding I/O channels

Installation environment requirements

Although it has a wide temperature range, it is recommended to avoid direct exposure to corrosive gases or liquids. The touch screen should be regularly cleaned to prevent sensitivity degradation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-