The ABB 3BHE004573R0143 UFC760BE143 interface board is a key component responsible for signal conversion and equipment interconnection in ABB industrial automation systems. It is designed to solve problems such as communication protocol differences and signal type mismatches between different devices. This interface board can achieve bidirectional conversion of digital signals and analog signals, protocol adaptation of different communication buses, and efficient data exchange between control units and peripheral devices (such as sensors, actuators, monitoring equipment, etc.). It is widely used in industrial fields such as power, petrochemicals, metallurgy, and intelligent manufacturing, and is the core hub for ensuring the collaborative work of various components in automation systems and stable and reliable data transmission.

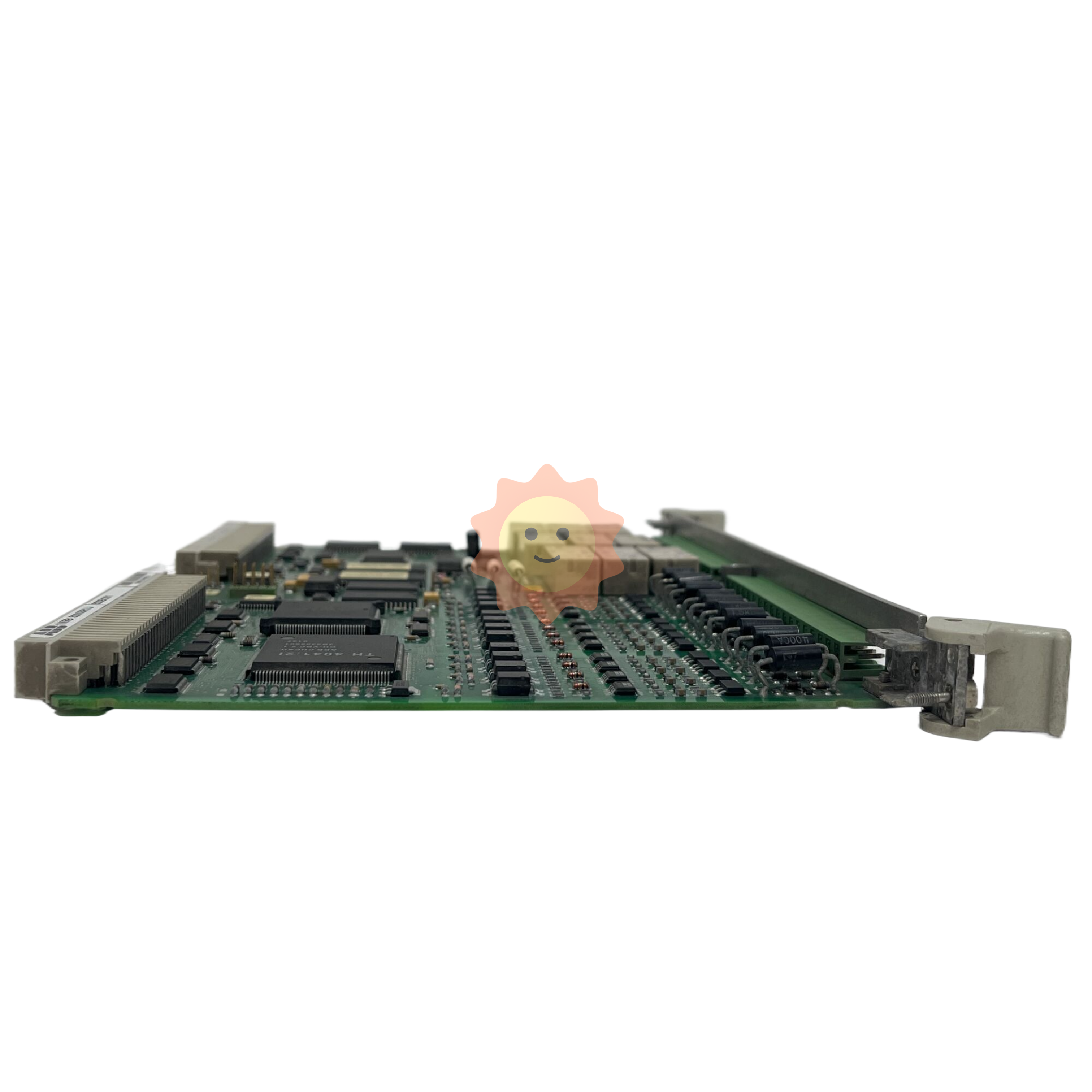

ABB 3BHE004573R0143 UFC760BE143 INTERFACE BOARD

Product Overview

The ABB 3BHE004573R0143 UFC760BE143 interface board is a key component responsible for signal conversion and equipment interconnection in ABB industrial automation systems. It is designed to solve problems such as communication protocol differences and signal type mismatches between different devices. This interface board can achieve bidirectional conversion of digital signals and analog signals, protocol adaptation of different communication buses, and efficient data exchange between control units and peripheral devices (such as sensors, actuators, monitoring equipment, etc.). It is widely used in industrial fields such as power, petrochemicals, metallurgy, and intelligent manufacturing, and is the core hub for ensuring the collaborative work of various components in automation systems and stable and reliable data transmission.

Core Basic Parameters

parameter category

Specific content

Product Model

3BHE004573R0143、UFC760BE143

manufacturer

ABB Group

core functionality

Signal conversion, protocol adaptation, device interconnection, data exchange

power supply voltage

Typical value: DC 24V (wide voltage compatible, please refer to the product manual for details)

Working temperature range

-10 ℃~55 ℃ (industrial grade environmental adaptability design)

Storage temperature range

-40℃ ~ 80℃

Signal processing type

Supports analog (4-20mA/0-10V) and digital (DI/DO) signal processing

Communication protocol support

Compatible with mainstream industrial communication protocols such as Modbus, PROFINET, EtherNet/IP, etc

Installation method

Standard DIN rail installation, compatible with ABB standard control cabinet layout

Dimensions

Meets industrial standard dimensions, subject to actual product and manual specifications

Core functional characteristics

1. Multi type signal adaptation capability

This interface board has a powerful signal conversion function, which can achieve bidirectional precise conversion between analog signals (such as 4-20mA current signals, 0-10V voltage signals) and digital signals, solving the problem of signal matching between different types of sensors and control units. At the same time, it supports filtering and amplification processing of signals, effectively suppressing interference signals in industrial sites and ensuring the accuracy of transmitted data.

2. Rich communication protocol compatibility

Built in multiple mainstream industrial communication protocol parsing modules, capable of protocol conversion and data transmission between different communication buses. Both traditional RS485 bus devices and Ethernet based PROFINET and EtherNet/IP devices can be connected to the same automation system through this interface board, breaking down communication barriers between devices and enhancing system integration flexibility.

3. High stability and anti-interference performance

Adhering to ABB's strict industrial grade product design standards, using high-quality components and reinforced circuit design, it has complete overvoltage, overcurrent, and short-circuit protection functions. At the same time, through EMC (Electromagnetic Compatibility) certification, it can effectively resist strong electromagnetic radiation, voltage fluctuations and other interference factors in industrial sites, ensure stable operation under complex working conditions, and reduce the bit error rate during signal transmission.

4. Convenient configuration and diagnostic functions

Support parameter configuration through ABB dedicated configuration software or web interface, allowing users to flexibly set signal types, communication protocols, data transmission rates, and other parameters according to actual application scenarios. The onboard rich status indicator lights (power lights, communication lights, fault lights, etc.) can provide real-time feedback on equipment operation status and data transmission, making it easy for on-site maintenance personnel to quickly locate faults and shorten maintenance time.

5. Good system compatibility

Specially designed for ABB automation systems, compatible with various ABB controllers PLC、 Seamless integration of human-machine interface and other devices without the need for additional adaptation modules. At the same time, it also supports compatibility and linkage with other brands of industrial equipment to meet the system upgrade and renovation needs of different users.

Applicable scenarios

-Power industry: In the DCS system of thermal power plants, data exchange between on-site sensors and the main control unit is achieved; Collection and transmission of equipment status signals in substations

-Petrochemical industry: In chemical plants, various detection instruments (temperature, pressure, flow meters) are connected to control modules to ensure real-time monitoring of production process parameters

-Metallurgical industry: In the steel rolling production line of a steel plant, signal interconnection between actuators (valves, motors) and control systems is achieved to accurately control the production process

-Intelligent Manufacturing: On an automated production line, responsible for communication and coordination between different brands of equipment, achieving collaborative operation and unified data management of the production line

-Industrial automation transformation: In the process of upgrading old systems, solve the problem of signal and protocol incompatibility between new and old equipment, and reduce the cost of transformation

5、 Precautions for use

Before installation, it is necessary to verify whether the interface board model matches the system requirements, strictly follow the product manual for wiring operations, ensure correct power polarity and signal line connections, and avoid equipment damage caused by wiring errors.

2. The installation location should be far away from strong electromagnetic interference sources (such as high-power motors, frequency converters) and high temperature, humid, and dusty areas. If necessary, shielding and heat dissipation measures should be taken to ensure the normal working environment of the equipment.

Before configuring the parameters, it is necessary to clarify the communication protocol, signal type, and other requirements of the system. After the configuration is completed, functional testing must be conducted to confirm that data transmission is normal and signal conversion is accurate before it can be put into formal operation.

4. During daily maintenance, it is necessary to regularly check the operation status of the interface board, the tightness of the wiring terminals, and the display status of the indicator lights. If any looseness or abnormality is found, it should be dealt with in a timely manner to avoid signal transmission interruption.

When the equipment malfunctions, the power supply should be cut off first and inspected and repaired by qualified technicians. Non professionals are prohibited from disassembling or modifying the equipment parameters without authorization.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-