Rolls-Royce 42022 - ULSTEIN Key for Marine

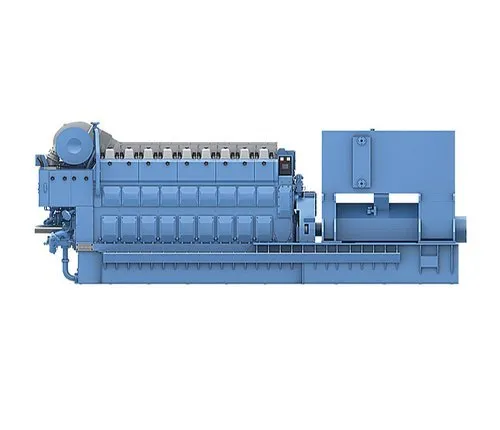

The Rolls-Royce 42022 stands out as a premier solution within Rolls-Royce automation products, specifically engineered for demanding environments such as the power industry, petrochemical plants, and general automation applications. This model delivers exceptional input/output capacity, featuring a robust I/O interface capable of handling up to 256 digital and analog signals simultaneously, ensuring seamless integration with complex control systems. Its high-speed processing unit supports real-time data acquisition and control, with cycle times reduced to milliseconds, optimizing responsiveness and operational precision. Durability is a hallmark of the Rolls-Royce 42022. Built with industrial-grade components and housed in a ruggedized enclosure rated for IP67, it withstands harsh environments characterized by extreme temperatures, humidity, and corrosive atmospheres common in petrochemical and power generation facilities. The 42022’s thermal management system ensures consistent performance even under heavy load, with an MTBF (Mean Time Between Failures) exceeding 100,000 hours, making it a reliable cornerstone for mission-critical automation infrastructure. In terms of performance metrics, the Rolls-Royce 42022 supports modular expansion, enabling customization to fit diverse operational needs.

The model integrates advanced communication protocols, including Ethernet/IP, Modbus TCP/IP, and PROFIBUS, facilitating interoperability with legacy systems and cutting-edge automation platforms. Its embedded diagnostics and predictive maintenance features provide proactive alerts, minimizing downtime and optimizing plant efficiency. Real-world applications of the Rolls-Royce 42022 demonstrate its versatility and robustness. In the power industry, it serves as the central controller for turbine management systems, ensuring precise regulation of speed, temperature, and pressure parameters. Within petrochemical plants, the 42022 excels in controlling complex distillation processes and safety interlocks, where reliability and rapid response are paramount. Its adaptability also extends to general automation scenarios, such as manufacturing lines and process control systems, where it harmonizes multiple sensor inputs and actuator outputs for streamlined operations. When compared to other Rolls-Royce models, the 42022 offers distinct advantages. Unlike the Rolls-Royce TDI-11, which focuses primarily on diagnostic interfaces, the 42022 integrates both control and monitoring functions within a single unit, reducing system complexity and footprint. Compared to the Rolls-Royce POSCON V.3, which is optimized for position control tasks, the 42022 offers enhanced scalability and broader protocol support, making it suitable for multi-disciplinary automation environments.

Additionally, the 42022’s durability surpasses that of the Rolls-Royce 222-656, which is more suited to indoor applications with less stringent environmental demands. Alongside the Rolls-Royce 42022, the Rolls-Royce H1111.0103 and Rolls-Royce 222-653 Plc2001b.PCB provide complementary programmable logic control capabilities, enhancing the automation ecosystem within petrochemical and power plants. For marine-related automation or cargo control systems, models like the Rolls-Royce Kamewa Cargo Control and Rolls-Royce AQUAMASTER ATC3 can be integrated seamlessly with the 42022 for extended functionality. The Rolls-Royce Loop Thruster Control and Rolls-Royce VTR-5-PY further augment operational control in specialized applications, while the Rolls-Royce Control Panel and Rolls-Royce CE05-00 offer user interface solutions designed to complement the 42022’s advanced control capabilities. In summary, the Rolls-Royce 42022 is a sophisticated, high-performance automation controller that excels in rigorous environments typical of the power industry, petrochemical processes, and general automation applications.

Its superior input/output capacity, durability, and versatile communication support set it apart from other models such as the Rolls-Royce TDI-11, POSCON V.3, and 222-656. When integrated with related products like the Rolls-Royce H1111.0103, Kamewa Cargo Control, and AQUAMASTER ATC3, the 42022 forms the backbone of a comprehensive automation solution, ensuring operational efficiency, safety, and reliability. For industries seeking a robust and scalable automation platform, the Rolls-Royce 42022 remains the benchmark for excellence in the application of automation technology.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-