ABB 704.910.4 contact block strip is a core supporting component in ABB's industrial control component series, mainly used in combination with main switch equipment such as position switches and travel switches, to achieve circuit on/off control and signal transmission through precise contact coordination. As a key contact execution unit of switchgear, this product, with ABB's exquisite manufacturing technology and strict quality control, has the characteristics of stable contact, wear resistance, and strong adaptability. It is widely used in industrial automation production lines, mechanical equipment control, power system regulation and other fields, providing a basic guarantee for the reliable operation of various control circuits.

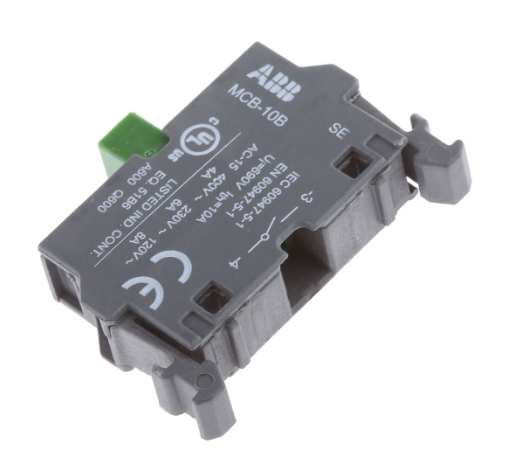

ABB 704.910.4 contact block strip

Product Overview

ABB 704.910.4 contact block strip is a core supporting component in ABB's industrial control component series, mainly used in combination with main switch equipment such as position switches and travel switches, to achieve circuit on/off control and signal transmission through precise contact coordination. As a key contact execution unit of switchgear, this product, with ABB's exquisite manufacturing technology and strict quality control, has the characteristics of stable contact, wear resistance, and strong adaptability. It is widely used in industrial automation production lines, mechanical equipment control, power system regulation and other fields, providing a basic guarantee for the reliable operation of various control circuits.

The core function of the contact block strip is to achieve reliable contact and separation of contacts through linkage with the switch operating mechanism, thereby completing the transmission of electrical signals or circuit switching. The ABB 704.910.4 model has been optimized for high-frequency operation requirements in industrial scenarios, and can maintain stable electrical performance in complex working environments. It is an important component in improving the overall reliability of switchgear.

Core Features

1. Stable and reliable contact performance

The contact block is made of highly conductive silver alloy contact material, with extremely low contact resistance and excellent stability, effectively reducing energy loss during current transmission and avoiding problems such as contact erosion and signal distortion caused by poor contact. The contact surface has undergone special electroplating treatment to enhance its oxidation resistance and wear resistance, ensuring that it can maintain a good contact state under long-term high-frequency operation and extending the product's service life.

2. High strength structural design

The base of the contact block is made of high temperature and impact resistant engineering plastic material, which has excellent mechanical strength and insulation performance, and can withstand the vibration, impact, and temperature fluctuations of industrial sites. The internal contact fixing structure has been optimized to effectively prevent displacement and looseness of the contacts during operation, ensuring consistency and reliability of contact actions and adapting to harsh industrial operating environments.

3. Wide adaptability and compatibility

The ABB 704.910.4 contact block strip adopts standardized structural dimension design, which can perfectly adapt to ABB 704 series position switches and multiple industrial switches of the same type, and can be quickly assembled without additional modification of installation structure. Its flexible installation method and contact configuration can meet different circuit control requirements, providing convenience for equipment upgrades, maintenance and replacement, and reducing equipment operation and maintenance costs.

4. Excellent environmental resistance performance

The product has good dust and moisture resistance, and can effectively resist the erosion of internal contacts by harmful substances such as dust, oil, and water vapor in industrial sites. At the same time, its working temperature range covers -25 ℃ to+85 ℃, which can adapt to extreme working conditions such as high and low temperatures. It can still work stably in harsh environments such as metallurgy, chemical industry, and mining, improving the environmental adaptability of the equipment.

5. Convenient installation and replacement

The contact block strip adopts a snap on or bolt type quick installation structure, with a simple and efficient installation process that can be assembled and fixed without the need for complex professional tools. The product identification is clear, making it easy for operators to quickly identify the contact function and wiring method. It can be quickly disassembled and replaced during later maintenance, reducing equipment downtime and improving production efficiency.

Key technical parameters

model

704.910.4

Contact material

Silver alloy (AgCdO/AgSnO ₂)

Number of contact points

2 groups/3 groups (optional, single pole double throw/double pole single throw)

rated voltage

AC 690V / DC 250V

rated current

10A (resistive load), 5A (inductive load)

contact resistance

≤ 50m Ω (initial state)

insulation resistance

≥100MΩ(500V DC)

Withstand Voltage

AC 2500V (no breakdown for 1 minute)

Working temperature range

-25℃ ~ +85℃

mechanical life

≥ 10 million times

Electrical life

≥ 1 million times (under rated load)

Installation method

Snap on/bolted fixation

Adaptive switch series

ABB 704 series position switches and industrial switches of the same specifications

Typical application scenarios

1. Industrial automation production line control

In automated production lines such as automobile manufacturing and electronic component assembly, ABB 704.910.4 contact block strips are used in conjunction with position switches to detect the movement position of conveyor belts and robotic arms. The control of equipment start stop, direction change, etc. is achieved through contact opening and closing, ensuring precise connection between various processes of the production line and improving production efficiency and product qualification rate.

2. Control and protection of power equipment

In substations and distribution equipment, the contact block serves as an auxiliary contact element for circuit breakers and isolating switches, used to transmit the opening and closing status signals of the equipment, provide accurate feedback on the equipment operation status for the power control system, achieve automatic monitoring and fault protection of the power system, and ensure stable and reliable power supply.

3. Mechanical equipment safety interlock

In mechanical equipment such as machine tools and presses, the contact block bar is linked with the safety position switch to form the safety interlock circuit of the equipment. When the protective door of the equipment is not closed and the moving parts exceed the safe range, the contact strip contacts will disconnect, cutting off the equipment operation circuit, preventing safety accidents, and ensuring the personal safety of operators.

4. Control of Rail Transit Equipment

In subway, light rail and other rail transit systems, this contact block strip is used for train door control, track signal detection and other equipment. With its excellent vibration resistance and environmental resistance, it can stably transmit control signals in complex rail transit environments, ensuring the safety and efficiency of train operation.

5. Control of chemical and metallurgical equipment

In high-temperature and high dust equipment such as chemical reaction vessels and metallurgical furnaces, ABB 704.910.4 contact block strips are used in conjunction with high-temperature resistant position switches to detect parameters such as valve opening and furnace position. Its stable contact performance and environmental resistance ensure reliable transmission of equipment control signals and ensure stable production processes.

Installation and usage precautions

-Adaptability confirmation: Before installation, it is necessary to confirm that the contact block model is consistent with the matching switch equipment model, check the appearance of the product for any damage, and ensure that the contacts are not deformed or oxidized, to ensure that the product meets the voltage and current level requirements of practical applications.

-Installation operation specifications: During installation, follow the product installation instructions to ensure smooth linkage between the contact block strip and the switch mechanism, tight contact of the contacts, and no jamming; The fixing bolts need to be tightened to prevent the contact block from loosening and shifting due to vibration during equipment operation.

-Wiring requirements: When wiring, it is necessary to distinguish between the normally open and normally closed properties of the contacts, accurately wire according to the circuit schematic, ensure that the wiring terminals are fastened, and avoid problems such as increased contact resistance and heating caused by loose wiring; After the wiring is completed, insulation testing is required to prevent short circuit faults.

-Environmental protection measures: When used in environments with high dust concentration, high humidity, or corrosive gases, protective covers should be installed on the supporting switchgear and contact blocks to prevent harmful substances from directly contacting the contacts and affecting product performance; Ensure good heat dissipation in high temperature environments and avoid exceeding the rated operating temperature of the product.

-Maintenance and testing: Regularly inspect the contact block strip, clean the dust and oxide layer on the contact surface; By using a multimeter to measure the contact resistance of the contacts, if it is found that the resistance value has significantly increased, the contacts are severely worn, or there are burn marks, the contact block strip should be replaced in a timely manner to ensure the reliability of the circuit control.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-