The YOKOGAWA 8596020000 digital I/O module is an industrial grade digital input/output module launched by Yokogawa Electric in Japan. It belongs to the core spare parts category of PLC systems and is mainly used for the acquisition of switch signals and the execution of control instructions in industrial automation scenarios. This module adopts a highly reliable isolation design and is perfectly compatible with mainstream control systems such as Yokogawa Centum-ST2. It achieves stable connection of external devices through dedicated KS2 cables and can accurately interface input devices such as sensors and buttons, as well as output actuators such as relays and solenoid valves. It provides core data transmission and control support for discrete control and status monitoring in industrial production processes. Its modular structure design not only facilitates installation and maintenance, but also allows for flexible expansion according to the actual needs of industrial sites, widely adapting to the application requirements of various complex industrial environments.

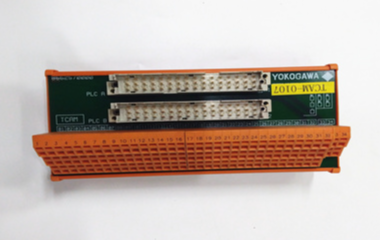

YOKOGAWA 8596020000 Digital I/O Module

Product Overview

The YOKOGAWA 8596020000 digital I/O module is an industrial grade digital input/output module launched by Yokogawa Electric in Japan. It belongs to the core spare parts category of PLC systems and is mainly used for the acquisition of switch signals and the execution of control instructions in industrial automation scenarios. This module adopts a highly reliable isolation design and is perfectly compatible with mainstream control systems such as Yokogawa Centum-ST2. It achieves stable connection of external devices through dedicated KS2 cables and can accurately interface input devices such as sensors and buttons, as well as output actuators such as relays and solenoid valves. It provides core data transmission and control support for discrete control and status monitoring in industrial production processes. Its modular structure design not only facilitates installation and maintenance, but also allows for flexible expansion according to the actual needs of industrial sites, widely adapting to the application requirements of various complex industrial environments.

Specification parameters

1. Core channel parameters

-Input channel: 16 digital inputs, supporting two modes of contact input and voltage input; The standard for contact input signal is: 100k Ω and above in OFF state, and 200 Ω and below in ON state; The voltage input signal standard is: OFF state 4.5~25V DC, ON state ± 1V DC, and impedance of 200 Ω or less.

-Output channel: 16 digital output channels, using transistor contact type, compatible with both inductive and resistive loads, with a maximum load capacity of 30V DC and 100mA.

2. Electrical parameters

-Input contact rating: 5V DC, 20mA and above.

-Power requirement: The working voltage is 5V DC, and the maximum current consumption is 450mA.

-Output response time: ≤ 16ms, ensuring fast execution and feedback of control instructions.

3. Functional parameters

-Pulse function: Supports pulse width setting from 8ms to 7200s, with a pulse resolution of 8ms; optional/P function code to achieve pulse width control or time proportional output function.

-Compatibility standard: Optional/G3 function code, compliant with ISA G3 standard, suitable for specific industrial scene specifications.

4. Physical and environmental parameters

-Connection method: Special KS2 cable is used for external connection to ensure the stability and anti-interference of signal transmission.

-Installation method: Supports positioning hole guide rail installation, compatible with industrial site standardized installation specifications.

-Working environment: Suitable for industrial wide temperature working range, with good anti vibration and anti electromagnetic interference capabilities, meeting the requirements of harsh industrial environments.

Performance characteristics

1. High reliability and stability

The module adopts a full channel isolation design, effectively avoiding the impact of external electromagnetic interference and signal crosstalk on data acquisition and control output, significantly improving the stability of operation in complex industrial electromagnetic environments. By selecting industrial grade high weather resistant components and undergoing rigorous environmental adaptability testing, they can operate stably for a long time in harsh industrial environments such as high and low temperatures, high humidity, and high dust, reducing equipment failure rates.

2. Flexible signal adaptation capability

The input channel is compatible with two mainstream input types: contact signals and voltage signals, and can be connected to different types of digital input devices without the need for additional conversion modules, greatly improving the versatility of the module. The output channel supports both inductive and resistive load types, which can directly drive various industrial actuators, reduce intermediate transfer links, and improve the reliability of the control link.

3. Accurate control response and pulse function

Output response time ≤ 16ms, able to quickly respond to upper computer control instructions, ensuring real-time industrial control processes, suitable for production scenarios with high control accuracy requirements. Equipped with high-precision pulse width control function, the pulse resolution reaches 8ms, which can meet the application requirements of precise pulse signals such as flow control and stepper drive. The expandable time proportional output function can be selected through the function code to adapt to more complex control logic.

4. Convenient compatibility and scalability

Deeply compatible with mainstream control systems such as Yokogawa Centum-ST2, it can seamlessly integrate into existing industrial automation systems, reducing the cost of system upgrades and renovations. Modular design facilitates on-site installation, debugging, and maintenance, supports parallel expansion of multiple modules, and can be flexibly combined according to the input and output point requirements of industrial sites, enhancing the flexibility of system configuration.

Working principle

The core working logic of YOKOGAWA 8596020000 digital I/O module is divided into two core links: digital input acquisition and digital output control. The entire control loop is achieved through cooperation with the upper computer control system.

1. Principle of digital input

When external sensors, buttons, and other input devices generate switch signals, the signals are transmitted to the input channel of the module through a dedicated KS2 cable. The isolation circuit inside the module performs anti-interference processing on the input signal and converts the analog switch signal into a standard digital electrical signal (high/low level). Subsequently, the module transmits the converted digital signal to the upper control system through the internal bus to complete the acquisition of switch status. For different types of input signals, the built-in signal recognition circuit of the module can automatically adapt to ensure the accuracy of the collected data.

2. Principle of digital output

The upper control system generates control instructions based on the preset control logic and transmits them to the YOKOGAWA 8596020000 module through the system bus. After receiving instructions, the module converts digital control signals into electrical signals that can drive external actuators through internal logic processing, and transmits them to relays, solenoid valves, and other devices through output channels to achieve control actions such as start stop and switching of the equipment. For pulse control requirements, the module can accurately generate pulse signals with a set width based on upper level instructions, and achieve precise process control through time proportional output or pulse width control functions. At the same time, the built-in load protection circuit of the module can provide overcurrent and overvoltage protection for the output channel, avoiding damage to the module caused by abnormal loads.

Precautions

1. Installation and wiring safety

-Before installing and wiring the module, it is necessary to confirm that the external circuit is in a power-off state to avoid electric shock accidents or module damage caused by live operation.

-After wiring is completed, it is necessary to ensure that all terminals are securely fastened to prevent signal transmission abnormalities or equipment failures caused by poor contact.

-When used in combination with external current transformers, if the primary side of the transformer is in a powered state, it is strictly prohibited to disconnect the secondary side circuit, otherwise dangerous voltage may be generated; Before disassembling the module, the secondary side of the transformer must be short circuited first.

2. Operating standards for operation

-During the operation of the module, it is strictly prohibited to touch the input/output terminals and plug interfaces to avoid the risk of electric shock.

-When powered on, do not open the module casing or cover to prevent damage to internal circuits or safety accidents.

-It is prohibited to replace terminal plugs or switch relays during operation to avoid circuit short circuits or equipment failures.

3. Parameter matching and maintenance

-During use, it is necessary to strictly follow the rated parameters of the module and not exceed the limits of rated voltage and current to avoid module overload damage.

-Regularly inspect the module wiring terminals, clean the dust and debris at the terminals, and ensure stable signal transmission.

-The user manual for the module should be properly stored near the equipment for easy access by operators and maintenance personnel at any time; The manual should be retained until the module is scrapped.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-