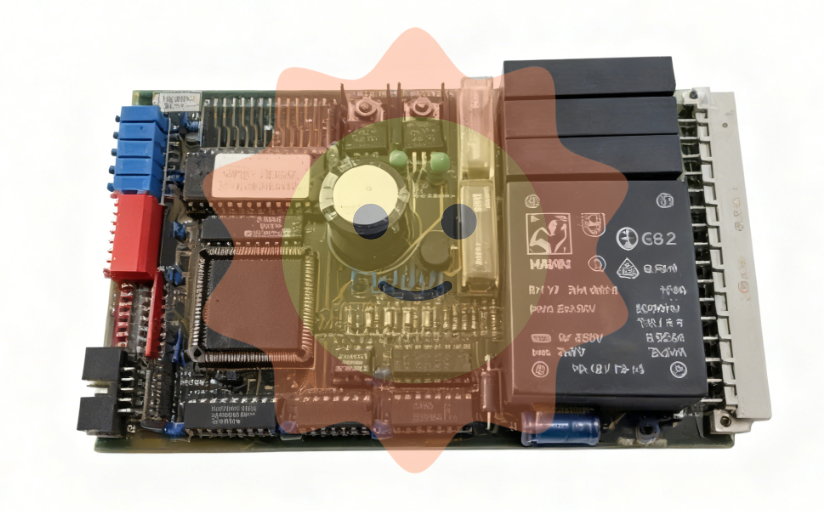

Rolls-Royce CCN 01 & SLIO 02 - CANMAN CONTROLLER NETWORK

The Rolls-Royce CCN 01 & SLIO 02 represent a pinnacle in automation technology, specifically engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. These advanced control and interface units are designed to deliver exceptional performance, reliability, and versatility, making them an essential component within complex industrial environments. At the core of the Rolls-Royce CCN 01 & SLIO 02 is a robust input/output (I/O) capacity that supports extensive data handling and real-time processing. The CCN 01 is engineered with multi-channel communication capabilities, allowing seamless integration with various sensors and actuators. It supports high-speed data transfer rates, ensuring timely response in critical operations. The SLIO 02 complements this with its scalable modular architecture, enabling flexible expansion of digital and analog I/O points to suit specific system requirements. Together, these modules provide a durable, high-performance solution capable of operating under harsh environmental conditions with superior electromagnetic compatibility and temperature tolerance. In terms of durability, the CCN 01 & SLIO 02 are built to withstand the challenges commonly faced in power generation facilities and petrochemical plants, including exposure to vibrations, dust, and corrosive atmospheres. Their ruggedized enclosures and conformal coating enhance longevity, reducing downtime and maintenance costs.

Performance metrics of these products include rapid cycle times, precise signal processing, and fault-tolerant design, which collectively contribute to enhanced system reliability and operational safety. The application of CCN 01 & SLIO 02 in power industry settings is particularly notable. These units excel in managing turbine control systems, generator protection schemes, and load distribution automation. Within petrochemical plants, they facilitate critical process control, including pressure monitoring, temperature regulation, and emergency shutdown sequences. Their role in general automation extends to factory floor control systems, integrating seamlessly with existing automation networks for optimized process efficiency. Comparing the Rolls-Royce CCN 01 & SLIO 02 to other Rolls-Royce automation products reveals several distinctive advantages. For instance, while the Rolls-Royce MPCF1-10.4" offers a sophisticated human-machine interface (HMI) for operational visualization, it does not provide the same level of I/O flexibility and ruggedness inherent to the CCN 01 & SLIO 02. Similarly, the Rolls-Royce HELICON-X-MP excels in marine propulsion control but lacks the specialized petrochemical process integration capabilities of the SLIO 02. Models such as the Rolls-Royce OBP 40018-A / CBP 40018L-A focus more on power conversion and protection, whereas the CCN 01 & SLIO 02 emphasize comprehensive control and monitoring across diverse industrial applications.

Alongside the Rolls-Royce CCN 01 & SLIO 02, we also offer complementary products like the Rolls-Royce Cct A310M and Rolls-Royce VTR-5-PY, which enhance system configurability and provide additional telemetry options. The Rolls-Royce Icon DP_94102, known for its intuitive data processing capabilities, pairs well with the CCN 01 for advanced automation schemes. For applications demanding precise load control, the Rolls-Royce Kamewa Load Control and Rolls-Royce AQUAMASTER ATC-3 provide specialized solutions that can be integrated with CCN 01 & SLIO 02 systems for comprehensive operational oversight. Additionally, the Rolls-Royce MPC200 and Rolls-Royce CANMAN CCN-11 extend communication protocols and network management, ensuring seamless interoperability within complex automation infrastructures. The Rolls-Royce automation products portfolio, including the CCN 01 & SLIO 02, is engineered to deliver unmatched reliability and performance in challenging industrial environments.

Their advanced technical features, combined with broad application versatility, make them the preferred choice for automation professionals in power generation, petrochemical processing, and beyond. Whether upgrading existing systems or designing new installations, leveraging the CCN 01 & SLIO 02 alongside models like the Rolls-Royce 5880-pc1025 rev.B and Rolls-Royce MEB-110 ensures a future-proof, scalable solution that drives operational excellence. In summary, the Rolls-Royce CCN 01 & SLIO 02 stand out as highly adaptable, durable, and efficient automation products tailored for demanding industries. Their superior I/O capacity, robust construction, and seamless integration capabilities position them as leaders in the application of CCN 01 & SLIO 02 in power industry, petrochemical, and general automation sectors. When combined with other trusted Rolls-Royce models, these units form the backbone of sophisticated control systems that empower operators to achieve optimal performance and reliability.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-