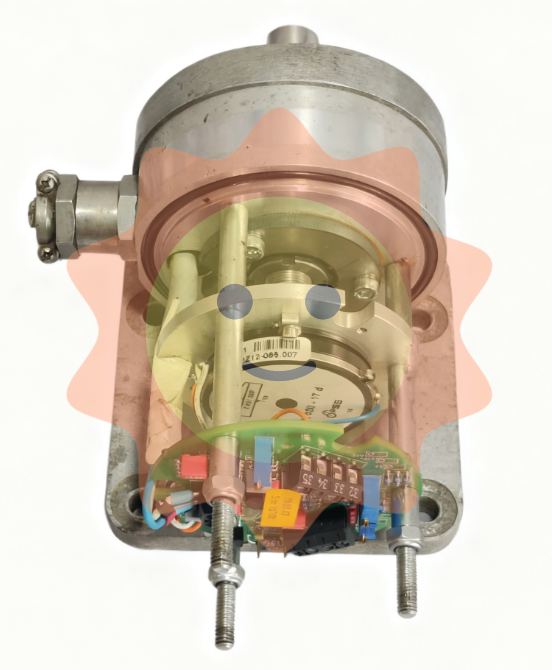

Rolls-Royce Bow Thruster Controller - Wh Deif DLQ72-pc-PY K852040

The Rolls-Royce Bow Thruster Controller stands as a pinnacle of precision and reliability within Rolls-Royce automation products, specifically engineered for demanding environments such as the power industry, petrochemical sectors, and general automation applications. This controller is designed to deliver seamless and responsive control over bow thrusters, crucial for vessel maneuverability and operational efficiency in complex industrial settings. At the core of the Rolls-Royce Bow Thruster Controller is its robust input/output (I/O) capacity, which supports a wide range of signal types including analog, digital, and pulse inputs. This versatility ensures compatibility with diverse thruster configurations and integration with existing automation systems. The controller’s durable architecture is built to withstand harsh industrial conditions, featuring high resistance to temperature fluctuations, vibration, and electromagnetic interference, which are common challenges in petrochemical and power plant environments. Performance-wise, the controller offers rapid response times and precise modulation capabilities, enabling fine-tuned thrust adjustments critical for dynamic operational demands such as docking, station-keeping, and emergency maneuvers. Real-world applications of the Rolls-Royce Bow Thruster Controller are extensive. In the power industry, it ensures reliable control of thrusters in power plant vessels, facilitating accurate positioning during fuel transfers and maintenance operations.

In the petrochemical sector, where safety and precision are paramount, the controller helps maintain vessel stability amidst variable sea conditions, thereby minimizing risk during cargo handling. Furthermore, in general automation, the controller integrates smoothly with broader plant control systems, enabling centralized monitoring and control, which enhances operational efficiency and reduces downtime. When compared to other Rolls-Royce automation products, such as the Rolls-Royce HELICON X3 or the Rolls-Royce PPSMI 2, the Bow Thruster Controller distinguishes itself through its specialized focus on thruster management combined with a highly customizable interface. While the HELICON X3 and HELICON systems provide broad automation solutions for engine and propulsion control, the Bow Thruster Controller offers unparalleled precision in thruster actuation and feedback mechanisms. Unlike the Rolls-Royce 5880-PC1028 or the 5880-pc1019, which are designed primarily for engine monitoring and diagnostics, the Bow Thruster Controller excels in real-time thrust vectoring and safety interlocks specific to bow thruster operation. Beyond its standalone capabilities, the Rolls-Royce Bow Thruster Controller complements other key Rolls-Royce models such as the Rolls-Royce 23083748, known for its advanced control protocols, and the Rolls-Royce U00E59, which provides sensor interfacing solutions.

Integration with the Rolls-Royce MPC-200 (A 7021100) enhances multi-parameter control setups, while pairing with the Rolls-Royce DC0033A enables seamless communication with distributed control systems. The controller also works effectively alongside the Rolls-Royce UN921 and the Rolls-Royce CP07-311, which are pivotal in power management and auxiliary control functions. Additionally, the Rolls-Royce PIP6-1 and Rolls-Royce GWY 01 provide complementary process interface and gateway functionalities ensuring an end-to-end automation ecosystem. In terms of durability, the Bow Thruster Controller incorporates ruggedized components similar to those found in the Rolls-Royce 5880-pc1002 Rev.A and the Rolls-Royce 5880-PC1025 REV.D, ensuring extended operational life and minimal maintenance needs under industrial stressors. This reliability is further enhanced by the controller’s compatibility with Rolls-Royce’s proprietary remote control systems, such as the Sistema De Control Remoto, enabling operators to execute precise thruster commands remotely, enhancing safety and operational flexibility.

In summary, the Rolls-Royce Bow Thruster Controller is an indispensable solution for industries requiring exacting control over vessel maneuvering under challenging conditions. Its industry-grade durability, expansive I/O capacity, and seamless integration with a suite of Rolls-Royce automation products make it the preferred choice for power industry, petrochemical, and general automation applications. Whether paired with the Rolls-Royce HELICON series, integrated into systems alongside the Rolls-Royce MPC-200, or supported by sensor and gateway units like the Rolls-Royce U00E59 and GWY 01, this controller guarantees optimized performance and operational excellence. For organizations seeking advanced automation technology with a proven track record, the Rolls-Royce Bow Thruster Controller delivers unmatched reliability and precision in the application of bow thruster control.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-