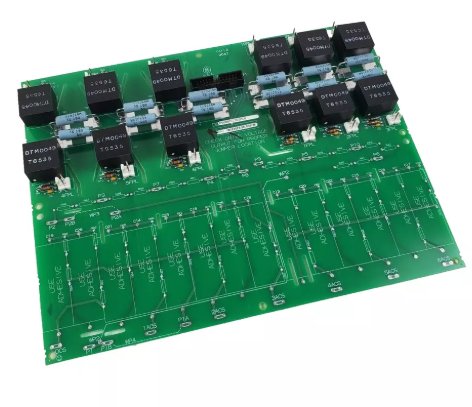

The GE DS200PCCAG1ACB power connection card is a core power distribution and management module tailored by General Electric (GE) for industrial control systems, and is a key component of the GE Speedtronic Mark VI series control system. This product mainly undertakes the functions of power access, distribution, conversion, and safety protection for industrial control equipment, providing stable and reliable power supply for the control systems of large rotating machinery such as gas turbines and steam turbines. It is the "power hub" that ensures the normal operation of various modules in the control system.

GE DS200PCCAG1ACB Power Connection Card

Product Overview

The GE DS200PCCAG1ACB power connection card is a core power distribution and management module tailored by General Electric (GE) for industrial control systems, and is a key component of the GE Speedtronic Mark VI series control system. This product mainly undertakes the functions of power access, distribution, conversion, and safety protection for industrial control equipment, providing stable and reliable power supply for the control systems of large rotating machinery such as gas turbines and steam turbines. It is the "power hub" that ensures the normal operation of various modules in the control system.

As an industrial grade power management component, it has high stability, strong anti-interference ability, and a complete protection mechanism, which can adapt to complex working conditions such as voltage fluctuations and electromagnetic interference in industrial sites. It is widely used in industries such as power, petrochemicals, and metallurgy that require strict reliability of control system power supply, laying a solid foundation for the continuous and stable operation of industrial production.

Core functions and roles

2.1 Power access and distribution

This is the core function of the module. The card supports multi specification input power supply access (such as AC 220V, DC 24V and other commonly used industrial power supplies). Through precise internal circuit design, the input power is stably distributed to various functional modules of the control system (such as overcurrent cards, signal acquisition cards, etc.), ensuring that each module can obtain power supply that meets the rated requirements. Its allocation mechanism has balance, which can avoid system failures caused by insufficient or overloaded power supply to some modules.

2.2 Power Conversion and Voltage Regulation

In response to the varying power requirements of different modules in the control system, DS200PCCAG1ACB integrates an efficient power conversion unit that enables flexible conversion between AC and DC, as well as different voltage levels (such as converting AC 220V to DC 24V). At the same time, the module is equipped with a high-precision voltage regulator circuit, which can effectively suppress the voltage fluctuations of the input power supply. The output voltage accuracy error is controlled within ± 2%, providing a stable power environment for sensitive electronic components and reducing the impact of voltage fluctuations on equipment performance.

2.3 Comprehensive Security Protection

The module is equipped with multiple protection mechanisms such as overvoltage, overcurrent, short circuit, and surge. When the input power supply experiences abnormal conditions such as high voltage, high current, or short circuit, the protection circuit will quickly act within microseconds. By cutting off the fault circuit, limiting the fault current, and other methods, it prevents the fault from spreading to the core module of the control system, avoiding equipment burnout or data loss. In addition, it has anti reverse connection function, which can effectively avoid module damage caused by confusion of the positive and negative poles of the power supply wiring.

2.4 Status Monitoring and Fault Feedback

The power connection card is equipped with a comprehensive status monitoring unit, which can real-time collect key parameters such as input/output voltage and current, and transmit monitoring data to the control system host through panel indicator lights or industrial bus. When the module itself or the power supply line fails, an alarm signal will be immediately issued, clearly indicating the type of fault (such as overvoltage alarm, overcurrent alarm, etc.), which facilitates the operation and maintenance personnel to quickly locate the root cause of the problem and shorten the troubleshooting time.

2.5 System Compatibility and Redundancy Support

Specially designed for the GE Speedtronic Mark VI control system, it has excellent compatibility and can be seamlessly integrated into the power architecture of existing control systems without the need for large-scale system modifications. At the same time, the module supports redundant power supply configuration and can work in conjunction with the backup power supply connection card. When the main power supply card fails, the backup module can automatically switch to operation, achieving uninterrupted power supply and improving the system's fault tolerance.

Key technical parameters

Input power specifications

Communication: 110V/220V ± 10%, 50/60Hz; DC: 24V/48V ± 15% (supports dual input)

Output power specifications

DC 24V/10A, DC 5V/5A, etc. (multiple outputs, customizable), output voltage accuracy ± 2%

conversion efficiency

≥ 92%, efficient and energy-saving, reducing energy loss

Protect response time

≤50μs, Quickly respond to power failures

communication interface

Compatible with GE dedicated bus, supporting real-time data exchange with Mark VI host

Working temperature range

-25 ℃~65 ℃, suitable for wide temperature industrial environment

Protection level

IP20 (module level), can achieve IP54 and above when combined with the control cabinet

Overall dimensions

Compliant with GE Mark VI cabinet slot standard, approximately 140mm x 90mm x 25mm (subject to actual product)

Redundant switching time

≤10ms, Realize uninterrupted power supply

Installation and usage precautions

4.1 Installation specifications

-Before installation, it is necessary to verify that the module model matches the power requirements of the control system, check the appearance of the module for scratches or damage, and ensure that the pins and wiring terminals are not oxidized or deformed.

-Strictly follow the installation manual of GE Speedtronic Mark VI control system, insert the module into the designated power slot of the cabinet, ensure that the module is in close contact with the slot and there is no looseness.

-When wiring, it is necessary to clearly distinguish between input terminals and output terminals, accurately connect power lines according to the wiring diagram, and separate AC and DC lines to avoid cross interference; After wiring is completed, be sure to tighten the terminal screws to prevent poor contact from causing heating or ignition.

-The installation location should be kept away from heat sources, water sources, and corrosive gases, with good ventilation. At least 5cm of heat dissipation space should be reserved around the module to avoid dense arrangement with other heating modules.

4.2 Key points of use and maintenance

-Before putting the module into use, it is necessary to use a multimeter to check whether the input power voltage meets the module specifications. After confirming that there are no errors, the power can be turned on; After the first power on, observe the status of the panel indicator light (normal if the power indicator light is always on and the fault indicator light is off), and at the same time check whether the output voltage is stable within the rated range.

-In daily operation, regularly check the input/output voltage, current and other parameters of the module through the control system monitoring interface. At least once a week, inspect the surface temperature of the module on site (normal operating temperature does not exceed 50 ℃). If abnormal heating occurs, stop the machine in time for troubleshooting.

-Clean and maintain the module once a quarter, using a dry brush to remove dust from the surface and wiring terminals, checking for loose wiring terminals and damaged insulation layers, and promptly addressing any issues found.

-If the module malfunctions and alarms, the input power should be cut off first, and then disassembled for inspection; When replacing the module, it is necessary to use genuine products of the same model. After replacement, power parameter calibration and redundancy switching testing (if configured with redundancy) should be carried out to ensure normal functionality.

-Avoid plugging or unplugging wiring or disassembling modules while they are live, to prevent static electricity or arc damage to internal electronic components.

Application scenarios

The GE DS200PCCAG1ACB power connection card serves as the power core of the GE Speedtronic Mark VI control system, with typical application scenarios including:

1. Gas turbine/steam turbine control system: provides stable power supply for turbine control units, monitoring modules, actuators, etc., ensuring the electrical reliability of the entire process control of turbine start-up, load regulation, shutdown, etc.

2. Main control system of thermal power plant: used for power distribution of unit DCS system (distributed control system), distributing stable power to core modules such as data acquisition card and logic control card, ensuring real-time monitoring and precise control of the power generation process.

3. Petrochemical compressor control system: adapted to the special environment of flammable and explosive chemical sites, providing safe and stable power supply for the pressure control, speed regulation and other modules of the compressor, avoiding production interruptions caused by power supply failures.

4. Metallurgical blast furnace control system: In high-temperature and high dust metallurgical environments, it provides strong anti-interference power supply for the material level control, temperature monitoring and other modules of the blast furnace, ensuring the continuous operation of metallurgical production.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-