ABB DSIH72VP ENOK is a multifunctional digital relay protection device designed specifically for the safety protection of critical equipment in power systems. Through precise monitoring and rapid response, it becomes the "safety guard" for core equipment such as generators, transformers, cables, and distribution lines. Its digital architecture breaks the functional limitations of traditional protective devices, balancing reliability and intelligence, and adapting to diverse needs from small and medium-sized industrial scenarios to large-scale power systems.

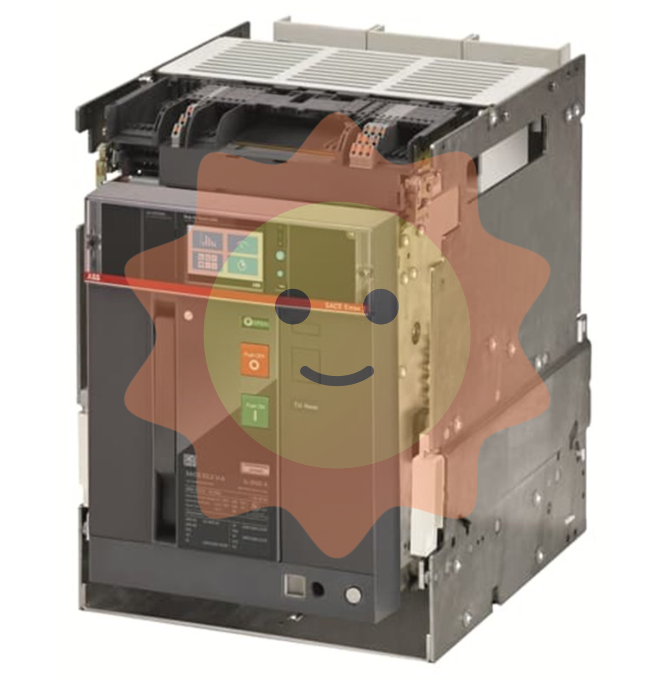

ABB DSIH72VP ENOK relay protection device

Product core positioning

ABB DSIH72VP ENOK is a multifunctional digital relay protection device designed specifically for the safety protection of critical equipment in power systems. Through precise monitoring and rapid response, it becomes the "safety guard" for core equipment such as generators, transformers, cables, and distribution lines. Its digital architecture breaks the functional limitations of traditional protective devices, balancing reliability and intelligence, and adapting to diverse needs from small and medium-sized industrial scenarios to large-scale power systems.

Core protection function

This device integrates the protection requirements of key scenarios in the power system, forming a three in one core protection system:

Overload protection: Real time monitoring of the matching between the circuit current and the rated carrying capacity of the equipment. When the current continues to exceed the threshold, graded warning or tripping action is taken to prevent equipment damage due to overheating. It is suitable for equipment such as motors and transformers that are prone to faults caused by load fluctuations.

Short circuit protection: Using high-precision current detection modules, it can identify fault types such as phase to phase short circuits and three-phase short circuits within milliseconds, quickly trigger circuit breaker action to cut off the fault circuit, and avoid instantaneous high temperature and electric force damage to the insulation layer and mechanical structure of equipment caused by short-circuit current.

Grounding protection: By monitoring the insulation status of the grounding system, it accurately identifies faults such as single point grounding and multi-point grounding, especially suitable for neutral point non effective grounding systems, which can effectively prevent equipment insulation breakdown and personal electric shock risks.

Core protection function

This device integrates the protection requirements of key scenarios in the power system, forming a three in one core protection system:

Overload protection: Real time monitoring of the matching between the circuit current and the rated carrying capacity of the equipment. When the current continues to exceed the threshold, graded warning or tripping action is taken to prevent equipment damage due to overheating. It is suitable for equipment such as motors and transformers that are prone to faults caused by load fluctuations.

Short circuit protection: Using high-precision current detection modules, it can identify fault types such as phase to phase short circuits and three-phase short circuits within milliseconds, quickly trigger circuit breaker action to cut off the fault circuit, and avoid instantaneous high temperature and electric force damage to the insulation layer and mechanical structure of equipment caused by short-circuit current.

Grounding protection: By monitoring the insulation status of the grounding system, it accurately identifies faults such as single point grounding and multi-point grounding, especially suitable for neutral point non effective grounding systems, which can effectively prevent equipment insulation breakdown and personal electric shock risks.

Applicable scenarios and industries

Based on its multifunctional characteristics and environmental adaptability, this device is widely used in:

Energy industry: neutral point protection for generators in thermal and hydroelectric power generation systems, low-voltage side protection for main transformers;

Manufacturing industry: feeder protection and motor protection for factory power distribution systems;

Transportation: Cable line protection for traction power supply systems in rail transit;

Infrastructure: Key distribution circuit protection for data centers and commercial buildings.

Key points for installation and maintenance

(1) Installation specifications

After the equipment arrives, it needs to undergo a visual inspection to confirm that there is no damage, deformation, or rust. At the same time, the module and accessory models and quantities should be checked according to the packing list;

The installation location should avoid strong magnetic field interference sources, ensure good ventilation, control the ambient temperature between -20 ℃~60 ℃, and the relative humidity should not exceed 95% (no condensation);

When wiring, it is necessary to strictly distinguish between power circuits, signal circuits, and trip circuits to avoid cross interference, and all wiring terminals must be securely fastened in place.

(2) Daily maintenance

Regularly check the equipment operation status indicator lights every month to confirm that the power, communication, and protection functions are normal;

Export operation logs through remote monitoring system every quarter to analyze the trend of changes in parameters such as current and voltage;

Conduct on-site verification once a year, with a focus on testing the accuracy and response time of protective action values to ensure compliance with technical specifications.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-