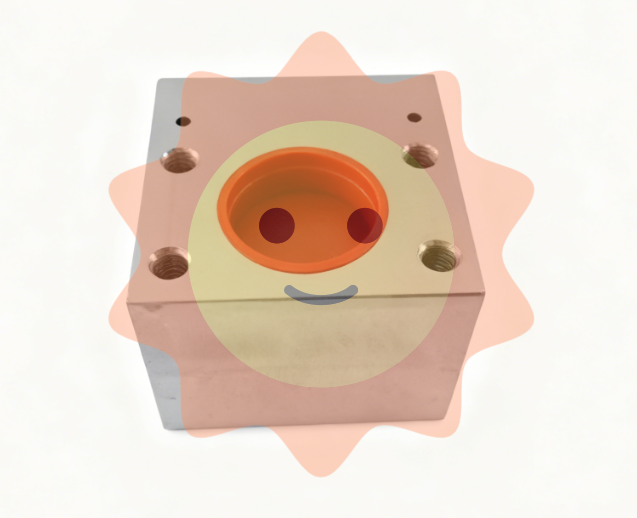

Rolls-Royce En-Tronic ft-110 - Control Ze544-110a-520 #1

The Rolls-Royce En-Tronic ft-110 stands as a pinnacle of innovation within the realm of automation technology, specifically engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Renowned for its robust architecture and advanced performance capabilities, the En-Tronic ft-110 offers exceptional input/output capacity, unparalleled durability, and precise control metrics that distinguish it among Rolls-Royce automation products. At the core of the Rolls-Royce En-Tronic ft-110 is its versatile input/output system, designed to handle high-density signal processing with ease. Supporting up to 128 digital inputs and 96 analog outputs, the ft-110 ensures seamless integration with complex industrial systems, enabling real-time data acquisition and responsive control. The unit operates with a rapid processing speed, boasting cycle times as low as 1 ms, which is critical for high-speed automation tasks where milliseconds can impact overall system efficiency. Built with industrial-grade components, the En-Tronic ft-110 is engineered to withstand extreme environmental conditions, including temperature ranges from -40°C to +70°C and resistance to electromagnetic interference, ensuring reliable operation in harsh petrochemical plants or power generation facilities. Durability is further enhanced by its ruggedized casing and conformal coating, making it resistant to dust, moisture, and vibration—common challenges in heavy industrial environments.

The system’s modular design facilitates easy maintenance and scalability, allowing operators to expand or modify configurations without extensive downtime. Additionally, the En-Tronic ft-110 supports multiple communication protocols such as Modbus, Profibus, and Ethernet/IP, enabling seamless integration into existing SCADA and DCS frameworks. In real-world applications, the Rolls-Royce En-Tronic ft-110 excels in optimizing processes where precision and reliability are non-negotiable. Within the power industry, it effectively manages turbine controls and load balancing, ensuring optimal energy distribution and minimizing downtime. Petrochemical plants benefit from its advanced monitoring and safety interlocks, which help in detecting faults and preventing hazardous situations through swift automated responses. Its adaptability makes it equally valuable in general automation scenarios, from complex assembly lines to infrastructure management, where it enhances operational efficiency and reduces human error. When compared to other models within the Rolls-Royce automation portfolio, the En-Tronic ft-110 distinguishes itself through its superior I/O density and processing speed.

For instance, while the Rolls-Royce LCD1026 B provides reliable display interfacing and user interaction, it does not match the ft-110’s robust control capabilities. Similarly, the Rolls-Royce BPC-1-0G-505E-00AE-A2V2-A1 excels in specific control applications but lacks the modular flexibility and environmental resilience found in the En-Tronic ft-110. Models such as the Rolls-Royce 5880-PC1025 REV.D and the Rolls-Royce PCC1030C offer complementary functions but are typically deployed in less demanding control scenarios or as part of subsystem integrations. Alongside the Rolls-Royce En-Tronic ft-110, we also offer the Rolls-Royce Aquamaster ACP122 and Rolls-Royce Load Control DQ96-c, which complement the ft-110 by providing specialized thruster and load management solutions, respectively. For enhanced system visualization and operator control, the Rolls-Royce Icon DP_94102 and Rolls-Royce UMAS UN-940 are ideal companions, offering advanced human-machine interface capabilities. In applications requiring remote control and monitoring, the Rolls-Royce Sistema De Control Remoto and Rolls-Royce Bow Thruster Controller integrate seamlessly, extending the operational reach of automation systems.

The application of En-Tronic ft-110 in the power industry, petrochemical, and general automation sectors demonstrates Rolls-Royce’s commitment to delivering cutting-edge solutions that combine performance, reliability, and versatility. Whether deployed alongside the Rolls-Royce 5880-PC1026 REV.A for enhanced processing or paired with the Rolls-Royce H1111.0102 for diagnostic functions, the ft-110 proves indispensable for operators looking to optimize complex industrial processes. In summary, the Rolls-Royce En-Tronic ft-110 sets a new standard in industrial automation by offering a powerful blend of high input/output capacity, rugged durability, and fast processing speeds tailored to demanding environments. Its seamless compatibility with a suite of Rolls-Royce automation products positions it as a cornerstone for modern control systems, driving efficiency and safety across the power industry, petrochemical plants, and diverse automation applications worldwide.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-