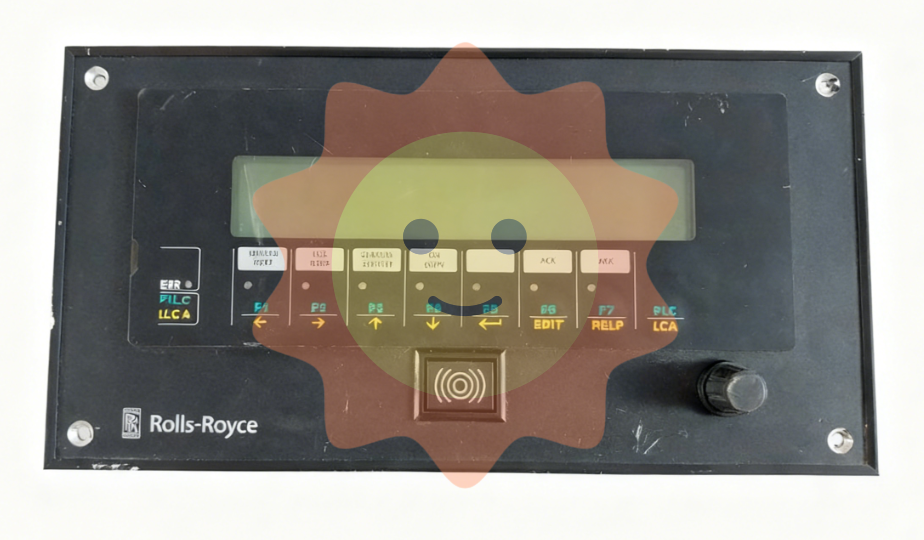

Rolls-Royce HATTELAND - 15 INCH TFT DISPLAY 100W 115VAC/60HZ

The Rolls-Royce HATTELAND is a pinnacle of engineering excellence within Rolls-Royce’s automation portfolio, designed specifically to meet the demanding requirements of the power industry, petrochemical sectors, and general automation applications. This robust system delivers superior input/output capacity, exceptional durability, and unparalleled performance metrics that set a new benchmark for industrial automation solutions. At its core, the Rolls-Royce HATTELAND boasts an advanced modular architecture that supports up to 512 input/output channels, enabling seamless integration with a wide range of sensors, actuators, and control devices. This high-capacity I/O capability ensures real-time data acquisition and precise control, critical for optimizing complex industrial processes. With an operating temperature range from -40°C to 85°C and a ruggedized enclosure rated to IP67, the HATTELAND is engineered to withstand harsh environments typical of petrochemical plants and power generation facilities, providing reliable performance in corrosive, high-vibration, and high-humidity conditions. Performance-wise, the HATTELAND features ultra-fast processing speeds with latency under 2 milliseconds, ensuring rapid response times essential for safety-critical automation tasks. Its built-in redundancy options and fault-tolerant design reduce downtime, increasing operational uptime in mission-critical applications.

The system supports multiple communication protocols including Modbus TCP/IP, Profibus, and CANopen, offering versatile connectivity options to integrate seamlessly with existing infrastructures. In real-world scenarios, the Rolls-Royce HATTELAND excels in applications such as turbine control in power plants, automated valve positioning in petrochemical refineries, and complex process control in manufacturing automation. For example, in the power industry, the HATTELAND can manage distributed control systems that regulate gas turbines, ensuring optimized fuel consumption and emission control. In petrochemical environments, it provides precise monitoring and actuation for chemical reactors, enhancing safety and product quality. Its adaptability also makes it an ideal choice for general automation tasks, including robotic assembly lines and packaging systems, where reliable input/output handling and fast processing are crucial. When compared to other Rolls-Royce automation products, the HATTELAND stands out for its exceptional scalability and ruggedness. While models like the Rolls-Royce UMAS-V and the Rolls-Royce HY200 3424 0170 offer specialized control solutions, the HATTELAND’s broad I/O capacity and environmental resilience make it a more flexible option across diverse industrial settings. Unlike the Rolls-Royce Load Control DQ96-c, which focuses primarily on load management, the HATTELAND delivers comprehensive automation control with enhanced fault tolerance.

Additionally, compared to the Rolls-Royce AQM 4 LSP007, which is optimized for specific sensor integration, the HATTELAND supports a wider range of communication protocols and larger system architectures. Alongside the Rolls-Royce HATTELAND, complementary products such as the Rolls-Royce KAMEWA AIU-3 and the Rolls-Royce G2 JOYSTICK provide intuitive human-machine interface solutions, enabling operators to monitor and adjust system parameters with ease. The Rolls-Royce SLIO-02 and Rolls-Royce UN925 models offer additional modular I/O and control options that can be integrated with HATTELAND to expand system capabilities. For applications requiring precise motor control, the Rolls-Royce MEG-100-101-102 series pairs effectively with HATTELAND, delivering synchronized automation performance. Furthermore, the Rolls-Royce RPM40017 and Rolls-Royce HCX LF80-01-20 complement HATTELAND in providing enhanced diagnostic and control features crucial for maintaining system health and efficiency. The application of HATTELAND in power industry, petrochemical, and general automation sectors is a testament to Rolls-Royce’s commitment to delivering cutting-edge automation products tailored for challenging industrial environments.

Its combination of high input/output capacity, rugged durability, and fast, reliable operation makes it an indispensable asset for engineers seeking to enhance process control, safety, and productivity. In summary, the Rolls-Royce HATTELAND represents an advanced automation solution uniquely suited for complex industrial applications. Its superior technical features and compatibility with other Rolls-Royce automation products such as the Rolls-Royce UN924, Rolls-Royce MEC210, and Rolls-Royce ATC3 ensure that it integrates seamlessly into existing systems while providing future-proof scalability. For industries aiming to leverage state-of-the-art automation technologies, the Rolls-Royce HATTELAND stands as a reliable, high-performance choice that elevates operational excellence across power generation, petrochemical processing, and general automation landscapes.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-