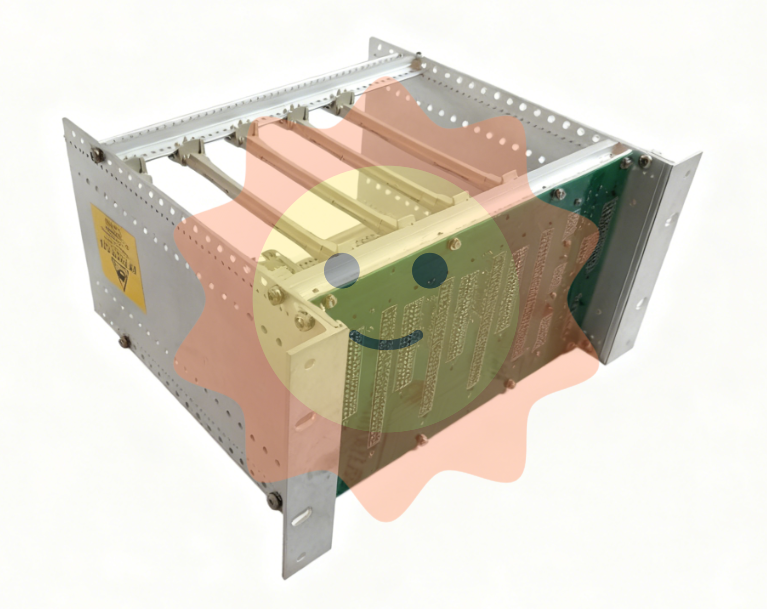

Rolls-Royce HCX CONTROL LEVER - PANEL LF80-01-20

The Rolls-Royce HCX CONTROL LEVER represents a pinnacle in precision control technology, designed specifically for demanding applications in the power industry, petrochemical plants, and general automation environments. Engineered with robust input/output capabilities, this control lever is optimized to deliver seamless operational command over complex machinery and systems, making it an indispensable component in critical industrial setups. Key technical features of the Rolls-Royce HCX CONTROL LEVER include a high-resolution input mechanism capable of processing analog and digital signals with minimal latency, ensuring responsive and accurate control. The lever supports a broad input voltage range from 5V to 24V DC, making it compatible with various power configurations commonly found in industrial control panels. Its output capacity includes multiple contact configurations that allow integration with both relay-based and PLC-driven systems, facilitating straightforward adaptation within existing infrastructure. Constructed from high-grade stainless steel and reinforced polymer composites, the HCX CONTROL LEVER guarantees exceptional durability even under harsh operating conditions characterized by extreme temperatures, vibrations, or corrosive atmospheres. Performance metrics highlight its ability to withstand over one million operational cycles without degradation in response fidelity, underscoring its reliability in continuous-duty scenarios.

In real-world applications, the Rolls-Royce HCX CONTROL LEVER excels where precision and durability are paramount. In the power industry, it serves as a critical interface for turbine governors and generator excitation controls, providing operators with tactile feedback and fine-tuned command over power output adjustments. Within petrochemical plants, the lever’s resilience to corrosive vapors and its precision control ensure safe and efficient regulation of valve actuators and pump speeds, contributing to process stability and safety compliance. General automation systems benefit from the HCX CONTROL LEVER’s compatibility with advanced supervisory control and data acquisition (SCADA) systems, enabling seamless integration and enhanced operator ergonomics in control rooms. When compared to other Rolls-Royce automation products, the HCX CONTROL LEVER stands out for its blend of mechanical robustness and electronic versatility. Unlike the Rolls-Royce G2 JOYSTICK, which primarily focuses on multi-axis directional control with limited output configurations, the HCX CONTROL LEVER offers a more extensive range of input/output customization tailored for industrial control frameworks.

Compared to the Rolls-Royce CANMAN CCN-01 and Rolls-Royce CANMAN SLIO 02, which provide modular communication and interface solutions, the HCX CONTROL LEVER excels as a direct physical control element with superior tactile feedback and mechanical endurance. Moreover, the HCX CONTROL LEVER’s design advances beyond models like the Rolls-Royce 5880-PC1026 REV.A and Rolls-Royce 5880-PC1028 by incorporating enhanced signal conditioning and noise immunity, critical in high-electromagnetic interference (EMI) environments typical of petrochemical and power plants. Alongside the Rolls-Royce HCX CONTROL LEVER, complementary models such as the Rolls-Royce MPC-300-A7029099 and the Rolls-Royce RPM40017 provide advanced processing and monitoring capabilities that enable full system automation and real-time feedback analysis. The Rolls-Royce P001240-1 and Rolls-Royce CE05-01 modules further augment control system flexibility, allowing integration of the HCX CONTROL LEVER into wider control architectures. For applications requiring specialized input devices, the Rolls-Royce SLIO-01 and Rolls-Royce ANA DIG units offer analog-to-digital conversion and signal multiplexing, enhancing the HCX CONTROL LEVER’s utility in complex automation scenarios.

The application of the HCX CONTROL LEVER in power industry, petrochemical, and general automation environments is a testament to Rolls-Royce’s commitment to engineering excellence and operational reliability. Its ability to maintain high performance under extreme conditions makes it a preferred choice for operators seeking consistent control with minimal maintenance. As part of the broader portfolio of Rolls-Royce automation products, the HCX CONTROL LEVER delivers a unique combination of precise manual control, rugged durability, and seamless integration—qualities that set it apart in a competitive market. In summary, the Rolls-Royce HCX CONTROL LEVER is a highly adaptable, durable, and precise control solution tailored for critical industrial applications. It complements and enhances the functionality of other renowned Rolls-Royce models such as the Rolls-Royce Spa-1, Rolls-Royce 222-653, and Rolls-Royce CMS, providing operators in power generation, petrochemical processing, and automation with a dependable tool for enhanced control and operational excellence. Whether deployed alongside the Rolls-Royce Thruster Panel in marine propulsion or integrated with the Rolls-Royce LIAAEN HELITRON DC0016A for sophisticated electronic control, the HCX CONTROL LEVER remains central to ensuring smooth, safe, and efficient industrial operations.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-