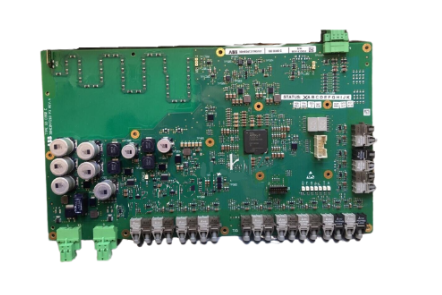

HIE300927R0101 UBC717AE101 is a core control board designed specifically for high-voltage inverter systems by ABB brand, belonging to the key component series of ABB high-voltage inverters. This board is developed based on ABB's mature power electronic control technology, with high reliability, strong anti-interference ability, and precise control performance. It is mainly used in high-voltage motor drive systems in industrial fields such as metallurgy, chemical industry, power, mining, and cement. As the "control center" of high-voltage frequency converters, it realizes real-time monitoring, precise regulation, and fault protection of motor operation status, ensuring stable and efficient operation of the entire transmission system.

ABB HIEE300927R0101 UBC717AE101 High Voltage Inverter Board

Product Overview

HIE300927R0101 UBC717AE101 is a core control board designed specifically for high-voltage inverter systems by ABB brand, belonging to the key component series of ABB high-voltage inverters. This board is developed based on ABB's mature power electronic control technology, with high reliability, strong anti-interference ability, and precise control performance. It is mainly used in high-voltage motor drive systems in industrial fields such as metallurgy, chemical industry, power, mining, and cement. As the "control center" of high-voltage frequency converters, it realizes real-time monitoring, precise regulation, and fault protection of motor operation status, ensuring stable and efficient operation of the entire transmission system.

As a dedicated board for ABB high-voltage inverters, its design strictly follows industrial environmental standards and can adapt to complex working conditions such as high temperature, high humidity, and strong electromagnetic interference, providing core guarantees for the long-term stable operation of high-voltage inverters. It is an important spare part choice to replace similar faulty boards and ensure production continuity.

Core functions and roles

1. Precise control signal processing

This board is responsible for the operation and signal processing tasks of the core control algorithm of the high-voltage frequency converter. It can receive control instructions from the upper computer, PLC, or on-site sensors (such as speed setting, start stop signals, etc.), perform real-time calculations through the built-in high-performance processor, generate accurate trigger signals, and control the on and off timing of the internal power module (such as IGBT) of the frequency converter, thereby achieving precise adjustment of output voltage and frequency, meeting the speed regulation requirements of high-voltage motors under different loads, and improving the controllability of production processes.

2. Real time status monitoring and feedback

The board integrates rich signal acquisition interfaces, which can real-time collect key operating parameters of high-voltage inverters, including output voltage, current, power, module temperature, DC bus voltage, etc. After the collected parameters are processed, they are fed back to the upper monitoring system through a communication interface to achieve remote monitoring of the equipment's operating status; On the other hand, it is used for closed-loop control inside the board to ensure that the operating parameters of the frequency converter are stable within the set range.

3. Comprehensive fault protection mechanism

To ensure the safety of high-voltage frequency converters and load motors, the board is equipped with comprehensive fault detection and protection functions. When detecting abnormal situations such as overcurrent, overvoltage, undervoltage, overheating, power module failure, communication interruption, etc., the board can respond within microseconds and immediately trigger protective actions (such as cutting off power module drive signals, issuing fault alarms, and interlocking frequency converter shutdown), effectively avoiding the expansion of faults, reducing the risk of equipment damage, and providing multiple guarantees for system safety.

4. Efficient communication and interconnection capabilities

The board supports the internal bus communication protocol of ABB high-voltage frequency converter system, and can achieve high-speed data exchange with the power unit, human-machine interaction interface (HMI), monitoring unit and other components of the frequency converter, ensuring fast transmission of control instructions and real-time sharing of operating data. At the same time, some models can be compatible with mainstream communication protocols such as industrial Ethernet and PROFINET through extended interfaces, making it easy to access factory level automation control systems and achieve centralized monitoring and scheduling.

Key technical parameters

parameter category

Specific parameters

Instructions

Model identification

HIEE300927R0101 / UBC717AE101

ABB official unique model code, used for product identification and spare parts matching

Working Voltage

Usually DC 24V ± 10%

Industrial standard control power supply ensures stable power supply for the board

Working temperature range

-20℃ ~ +60℃

Adapt to complex temperature environments in industrial sites

Processor performance

High performance 32-bit industrial grade MCU

Support real-time computation of complex control algorithms with fast response speed

Signal input/output

Analog quantity (4-20mA/0-10V), digital quantity (DI/DO)

Compatible with mainstream sensors and control device signals

communication interface

Internal bus, RS485 (optional), Ethernet (optional)

Meet communication needs at different levels

Protection level

IP20 (board level)

It needs to be installed inside a closed control cabinet for use

Applicable scenarios and application areas

As the core component of ABB high-voltage frequency converters, this board is highly compatible with the application fields of high-voltage frequency converters, mainly concentrated in industrial scenarios that require high-voltage high-power motor drives, including:

-Metallurgical industry: used for high-voltage motor control of equipment such as rolling mills, blast furnace fans, and converter oxygen guns, to achieve precise speed regulation and energy-saving operation in the production process.

-Chemical industry: Suitable for equipment such as chemical reaction kettle stirring motors, centrifugal compressors, material conveying pumps, etc., to ensure the stability and safety of chemical processes.

-Electric power industry: used for high-voltage motor control of auxiliary equipment such as induced draft fans, supply fans, and feed pumps in thermal power plants, reducing power plant energy consumption and improving operational efficiency.

-Mining industry: Adapt key equipment such as mine hoists, main ventilation fans, and belt conveyors to ensure the continuity and safety of mining production.

-Cement industry: High voltage motor drive for equipment such as cement rotary kilns, raw material mills, and cement mills, optimizing production processes and reducing energy consumption.

Installation and usage precautions

1. Installation specifications

Before installation, it is necessary to ensure that the high-voltage inverter is in a power-off state and to discharge the relevant circuits to avoid the risk of electric shock; The board must strictly follow the installation manual of ABB frequency converter, align with the card slot and insert smoothly to ensure good contact of the connectors, and avoid signal transmission abnormalities or equipment failures caused by loose installation; During the installation process, it is necessary to avoid forcefully plugging and unplugging to prevent damage to the board pins or internal components.

2. Environmental requirements

The control cabinet for board installation should have good ventilation and heat dissipation conditions to avoid the performance degradation of the board due to high temperature environment; At the same time, dust and moisture prevention measures should be taken to prevent dust and water vapor from entering the control cabinet, which may affect the service life of the board; In addition, the control cabinet should be kept away from strong electromagnetic interference sources (such as high-power transformers, welding machines, etc.), and shielding measures can be taken if necessary.

3. Debugging and maintenance

After the installation of the board, it is necessary to configure and calibrate the parameters through the ABB frequency converter debugging software to ensure that the board matches and coordinates with other components of the frequency converter; In daily maintenance, it is necessary to regularly check the power supply voltage of the board, the contact condition of the connectors, and whether there is dust or oil accumulation on the surface of the board. If there is, it needs to be cleaned in a timely manner; If any abnormality is found in the board indicator light or related fault codes are reported by the frequency converter, professional technicians should be contacted in a timely manner for inspection and maintenance to avoid disassembling the board without authorization.

4. Replacement of spare parts

When replacing the board, it is necessary to choose a product that is exactly the same as the prototype number (HIEE300927R0101 UBC717AE101) to avoid using alternative models that may cause equipment incompatibility or operational failures; After replacement, it is necessary to re import and debug the parameters to ensure that the frequency converter resumes normal operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-