HIES208441R is a high-performance interface module launched by ABB for the industrial automation field. It adopts standardized modular design and integrates multiple signal processing and communication conversion functions. Its core function is to achieve a "bridge connection" between industrial equipment of different interface types and signal formats, which can not only complete the bidirectional conversion of analog and digital quantities, but also support the parsing and conversion of multiple industrial communication protocols, while having functions such as signal isolation and noise suppression. This module is compatible with various ABB control systems and third-party mainstream automation equipment. After rigorous industrial environment testing, it can operate stably for a long time under complex working conditions such as high temperature, high humidity, and strong electromagnetic interference. It is a core component for improving the compatibility and reliability of automation systems.

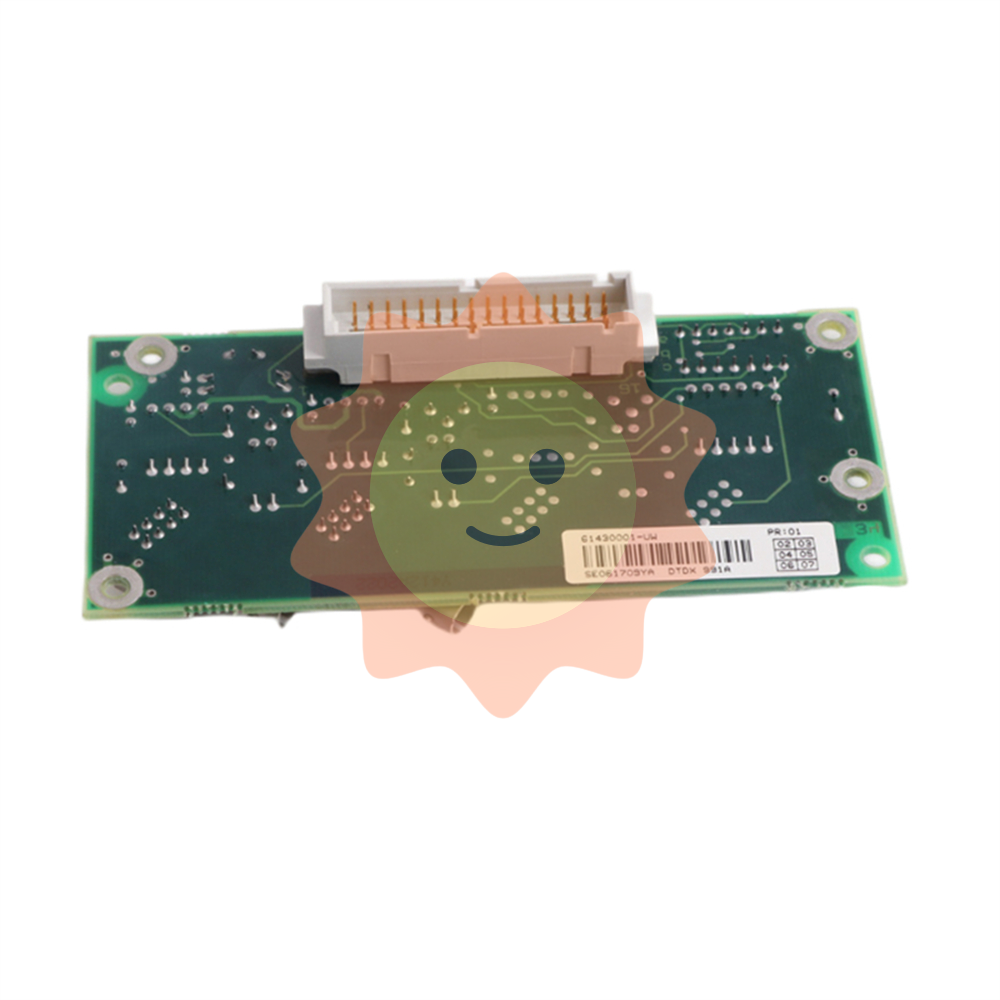

ABB HIES208441R interface module

Product Overview

HIES208441R is a high-performance interface module launched by ABB for the industrial automation field. It adopts standardized modular design and integrates multiple signal processing and communication conversion functions. Its core function is to achieve a "bridge connection" between industrial equipment of different interface types and signal formats, which can not only complete the bidirectional conversion of analog and digital quantities, but also support the parsing and conversion of multiple industrial communication protocols, while having functions such as signal isolation and noise suppression. This module is compatible with various ABB control systems and third-party mainstream automation equipment. After rigorous industrial environment testing, it can operate stably for a long time under complex working conditions such as high temperature, high humidity, and strong electromagnetic interference. It is a core component for improving the compatibility and reliability of automation systems.

Core functional features

1. Compatible with multiple types of signals to achieve cross device connectivity

This interface module supports the access and conversion of various commonly used industrial signal types, including analog signals (such as 4-20mA current signals, 0-5V voltage signals), digital signals (such as TTL/CMOS levels, dry contact signals), and pulse signals. Through the internal signal conditioning circuit, the module can convert different types of input signals into unified standard output signals, or customize signal formats according to the requirements of the target device, effectively solving the interface incompatibility problem between sensors and controllers, controllers and actuators, and achieving seamless integration of various industrial equipment.

2. Multi protocol conversion capability, suitable for complex communication networks

HIES208441R has built-in rich industrial communication protocol parsing modules, supporting bidirectional conversion of mainstream industrial communication protocols such as Modbus RTU/TCP, Profinet, EtherNet/IP, CANopen, etc. In complex automation systems composed of multiple brands of equipment, this module can serve as a communication gateway to enable data exchange between devices with different protocols. For example, it can convert sensor data using Modbus protocol into Profinet protocol data and transmit it to PLC, or convert EtherNet/IP control instructions from the upper computer into CANopen protocol instructions and send them to actuators, ensuring the smooth operation of the entire communication network.

3. Optoelectronic isolation design enhances the anti-interference performance of the system

In response to the strong electromagnetic interference problem in industrial sites, the module adopts comprehensive optoelectronic isolation technology to achieve electrical isolation between input signals, output signals, and module power supply, with an isolation voltage of up to 2kV AC. This design can effectively block external interference signals from entering the control system through signal lines, avoiding signal distortion, data loss, or equipment damage caused by interference. At the same time, the module is equipped with an EMC filtering circuit, which can further suppress power grid noise and RF interference, ensuring stable and reliable signal transmission in strong interference scenarios such as motor start-up and high-power equipment operation.

4. Flexible configuration methods to adapt to diverse needs

To meet the application needs of different industrial scenarios, HIES208441R provides multiple flexible configuration methods. Users can accurately set the signal conversion parameters, communication protocol types, data transmission rates, etc. of the module through ABB's dedicated configuration software (such as ABB Control Builder); At the same time, it supports local quick configuration through the built-in dip switch or button of the module, which is convenient for on-site debugging. In addition, the module also supports online modification and saving of parameters, allowing configuration updates to be completed without downtime and improving system maintenance efficiency.

5. Comprehensive diagnostic and protection functions to ensure safe operation

The module is equipped with a comprehensive self diagnosis and fault protection mechanism, which can monitor its own working status in real time, including power supply voltage, communication link, signal input and output status, etc. When detecting faults such as power overvoltage/undervoltage, communication interruption, signal abnormality, etc., the module will immediately send a local alarm signal through the fault indicator light and send fault diagnosis information to the upper computer through the communication interface, helping operation and maintenance personnel quickly locate the cause of the fault. At the same time, the module has an output short-circuit protection function, which can effectively avoid module damage caused by external circuit short circuits, and improve the safety and durability of the system.

6. Modular structure for easy system integration and expansion

Adopting a standardized modular structure design, HIES208441R can be directly installed on standard DIN rails, achieving a compact layout with other automation components and saving control cabinet space. The module supports cascading expansion of multiple units, and users can flexibly increase the number of modules according to the signal access quantity and communication requirements of the system, building a comprehensive interface conversion system with multiple channels and protocols. This expansion method does not require large-scale modifications to the existing system, reducing the cost and difficulty of system upgrades.

Key technical parameters

Signal input type

Analog quantity: 4-20mA (current), 0-5V/0-10V (voltage); Digital quantity: TTL/CMOS, dry contacts; Pulse quantity: 0-10kHz

Signal output type

Analog quantity: 4-20mA (current), 0-5V/0-10V (voltage); Digital quantity: TTL/CMOS, relay output

communication protocol

Supports Modbus RTU/TCP, Profinet, EtherNet/IP, CANopen

communication interface

RS485, Ethernet (RJ45), CAN bus

Isolation performance

Isolation between input/output/power supply, isolation voltage ≥ 2kV AC/1min

Conversion accuracy

Analog conversion accuracy ≤ ± 0.1% FS; digital response time ≤ 1ms

working power supply

DC 24V ± 15%, power consumption ≤ 8W

working environment

Temperature: -25 ℃ -70 ℃; Humidity: 5% -95% (no condensation); Protection level: IP20 (module level)

Installation method

Standard 35mm DIN rail installation

Overall dimensions

Width x Height x Depth: 35mm x 100mm x 120mm (typical value)

Typical application scenarios

The HIES208441R interface module, with its strong compatibility and reliability, is widely used in various industrial automation scenarios and has become a core component for connecting different devices and ensuring data transmission. Typical applications include:

1. Intelligent manufacturing production line: In intelligent manufacturing production lines such as automobile manufacturing and electronic processing, modules can be connected to sensors of different brands (such as temperature and pressure sensors), PLCs (such as ABB AC500, Siemens S7 series), and industrial robots to achieve unified collection of sensor data and precise issuance of PLC control instructions, ensuring the coordinated operation of various equipment in the production line.

2. Process control system: In process control scenarios such as petrochemicals and chemical pharmaceuticals, the module can convert the 4-20mA analog signal output by the on-site transmitter into a digital signal and transmit it to the DCS system. At the same time, it can convert the DCS control signal into a signal recognizable by the actuator, achieving precise control of process parameters such as temperature, pressure, and flow rate.

3. Power automation system: In power automation scenarios such as substations and power stations, modules can serve as communication gateways, connecting relay protection devices, power instruments, and other equipment with the upper monitoring system to achieve real-time uploading of equipment operation data and issuance of monitoring instructions, ensuring the safe and stable operation of the power system.

4. Intelligent warehousing and logistics system: In the intelligent warehousing and logistics sorting system, modules can be connected to barcode recognition devices, conveyor control modules, AGV (Automated Guided Vehicles) and other equipment to achieve communication and collaboration between various devices, improving the automation level and operational efficiency of warehousing and logistics.

5. Upgrading and retrofitting of old equipment: In industrial equipment upgrading and retrofitting projects, for old equipment that does not support mainstream communication protocols, modules can be connected to new automation control systems through signal conversion and protocol conversion functions, avoiding the high cost of overall equipment replacement and achieving intelligent upgrading of old equipment.

Precautions for use

1. Installation specifications: The module should be installed in a well ventilated location away from heat sources and strong electromagnetic radiation sources; When using DIN rail installation, it is necessary to ensure a firm installation and avoid module loosening caused by vibration; A certain amount of heat dissipation gap should be reserved between modules to prevent performance degradation in high-temperature environments.

2. Wiring requirements: Before wiring, it is necessary to confirm the voltage level of the module power supply, and it is strictly prohibited to connect power sources beyond the rated range; Signal lines and power lines should be laid separately to avoid parallel wiring and reduce electromagnetic interference; When wiring, it is necessary to firmly connect to prevent poor contact from causing signal abnormalities. After wiring is completed, insulation treatment should be done well.

3. Parameter configuration: Based on the signal type, communication protocol, and other parameters of the connected device, accurately set module parameters through configuration software or local dip switches; After the parameter configuration is completed, testing should be conducted to confirm that the signal conversion accuracy and communication link stability meet the system requirements, in order to avoid equipment communication failures caused by parameter errors.

4. Fault handling: When a module malfunctions, the fault type should be preliminarily determined through the fault indicator light and diagnostic information from the upper computer; When troubleshooting, it is necessary to disconnect the module power supply to avoid live operation; When replacing a module, ensure that the parameters of the new module are consistent with those of the original module to avoid affecting the normal operation of the system.

5. Regular maintenance: Clean the module regularly to remove surface dust and debris; Check the fastening of module wiring terminals and promptly address issues such as looseness and oxidation; Regularly test the signal conversion accuracy and communication stability of the module to ensure that its performance meets operational requirements.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-