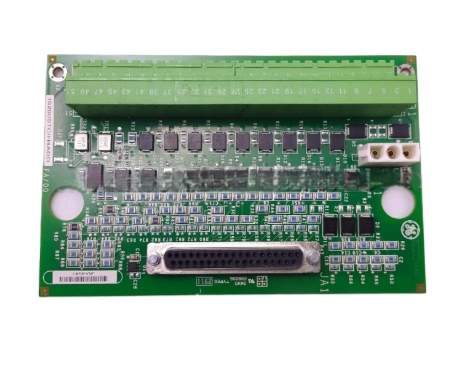

GE IS200AEADH4A (model 109W3660P001) is a high-performance input terminal board launched by General Electric (GE), which is a core component of the Mark VIe series control system. This product is designed specifically for industrial automation control scenarios, mainly responsible for signal transfer, isolation, and transmission between external devices such as sensors and actuators on site and the control system host. It is a key link in ensuring the stability and reliability of control system signal acquisition. Its design strictly follows industrial standards and can adapt to complex industrial environments such as high temperature, high humidity, and electromagnetic interference. It is widely used in large-scale unit control systems in heavy industries such as power, petrochemicals, metallurgy, and papermaking.

GE IS200AEADH4A 109W3660P001 Input Terminal Board

Product Overview

GE IS200AEADH4A (model 109W3660P001) is a high-performance input terminal board launched by General Electric (GE), which is a core component of the Mark VIe series control system. This product is designed specifically for industrial automation control scenarios, mainly responsible for signal transfer, isolation, and transmission between external devices such as sensors and actuators on site and the control system host. It is a key link in ensuring the stability and reliability of control system signal acquisition. Its design strictly follows industrial standards and can adapt to complex industrial environments such as high temperature, high humidity, and electromagnetic interference. It is widely used in large-scale unit control systems in heavy industries such as power, petrochemicals, metallurgy, and papermaking.

Core functions and advantages

1. Efficient signal conversion and acquisition

As the core function of the input terminal board, this product can achieve centralized access and conversion of multiple analog or digital signals. It has standardized terminal interfaces and supports direct connection with various common industrial sensors such as thermocouples, thermistors, pressure sensors, limit switches, etc., without the need for additional adaptation modules, effectively simplifying the on-site wiring process. At the same time, the internally optimized signal path design reduces signal transmission loss, ensuring that the collected raw signals can be accurately transmitted to the control system host, providing data support for the precise control of the unit.

2. Strengthen signal isolation and anti-interference capability

There are a large number of electromagnetic interference sources in industrial sites, such as high-power motors, frequency converters, etc., which can easily cause signal distortion or false triggering. The IS200AEADH4A input terminal board is equipped with a high-performance optoelectronic isolation module, which achieves electrical isolation between the input signal and the internal circuit of the system through optoelectronic conversion. The isolation voltage level can reach several thousand volts, effectively suppressing common mode interference and differential mode interference. In addition, the product adopts shielding design and anti-interference components, further improving the stability of signal transmission, and ensuring signal quality even in complex electromagnetic environments.

3. Stable and reliable industrial grade design

The product uses industrial grade high-strength PCB boards and high-quality connectors. The terminal block has good resistance to insertion and removal and contact stability, and can adapt to long-term and frequent on-site operations. In terms of environmental adaptability, its working temperature range covers -40 ℃ to 70 ℃, supporting stable operation in industrial scenarios with high humidity (relative humidity ≤ 95%, no condensation) and high dust, meeting the harsh environmental requirements of different regions and industries.

4. Convenient installation and maintenance

This terminal board adopts a standardized rail installation method, which can be quickly integrated into the cabinet of GE Mark VIe control system and seamlessly connected with other modules of the system. The terminal identification is clear and concise, making it easy for on-site engineers to connect, debug, and troubleshoot. At the same time, the product has good maintainability, and the modular design of key components makes replacement more efficient in case of failure, effectively reducing downtime.

Key technical parameters

Product Model

IS200AEADH4A / 109W3660P001

series

GE Mark VIe Control System

signal type

Supports analog input (such as 4-20mA, 0-10V) and digital input (dry contact, wet contact)

Number of input channels

16 routes (subject to actual configuration)

Isolation level

Isolation between input channels, isolation voltage ≥ 2500V AC (1 minute)

working power supply

DC 24V(±10%)

Operating Temperature

-40℃ ~ 70℃

Storage temperature

-55℃ ~ 85℃

relative humidity

5%~95% (no condensation)

Installation method

35mm DIN rail installation

Dimensions (length x width x height)

Approximately 120mm x 80mm x 30mm (subject to actual product)

Applicable scenarios and application cases

1. Applicable scenarios

-Thermal power plant: used for collecting temperature, pressure, flow and other parameters of steam turbine generator units, connecting on-site thermocouples, pressure transmitters and other equipment, providing signal support for unit speed regulation and excitation control.

-Petrochemical industry: used for monitoring process parameters of equipment such as reaction vessels and pipelines, such as collecting and transmitting signals of temperature, liquid level, concentration, etc., to ensure the stability and controllability of the production process.

-Metallurgical industry: Suitable for steel and non-ferrous metal smelting equipment, collecting signals such as furnace temperature, liquid level, and motor operation status to assist in the automation control of the smelting process.

-Light industries such as papermaking and textiles: used for collecting parameters such as speed, tension, and humidity on production lines to achieve precise control of the production process.

2. Typical application cases

A large thermal power plant adopts GE Mark VIe control system as the core control platform in the upgrading and renovation of steam turbine generator units, among which IS200AEADH4A input terminal board is widely used in the auxiliary system control of the unit. This terminal board is responsible for collecting temperature, vibration, pressure signals of auxiliary equipment such as water pumps and fans, as well as valve switch status signals. After isolation processing, the signals are transmitted to the controller. After the transformation, the stability of system signal acquisition has been significantly improved, the false alarm rate has been reduced by 80%, and the reliability of equipment operation and the power generation efficiency of the unit have been effectively improved.

Installation and usage precautions

1. Before installation, it is necessary to confirm that the product model matches the control system, check the appearance of the terminal board for any damage, and ensure that the connectors are not deformed, in order to avoid any impact on use due to transportation damage.

During the installation process, it is necessary to strictly follow the wiring diagram to ensure that the input signal type corresponds to the terminal interface, and to avoid equipment damage caused by reverse or incorrect connections.

3. When wiring, ensure that the wires are firmly connected to the terminals to avoid signal interruption or heating due to poor contact. The cross-sectional area of the wires should meet the load-bearing requirements of the terminal board.

4. The installation environment should be kept dry and ventilated, avoiding direct sunlight and rainwater erosion, and away from strong electromagnetic interference sources and high-temperature heat sources.

Before powering on the system, it is necessary to check the correctness of the wiring again. After confirming that there are no errors, slowly close the circuit and observe the status of the terminal board indicator lights (if available) to determine whether the equipment is starting normally.

6. During daily maintenance, it is necessary to regularly check the connection status of the terminals, clean the dust and debris on the surface of the terminals, and avoid insulation performance degradation caused by dust accumulation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-